Composite floor

A composite floor and board sticking technology, which is applied in the field of floor manufacturing, can solve problems such as easy deformation, and achieve the effects of preventing moisture deformation, reducing deformation rate, and facilitating installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

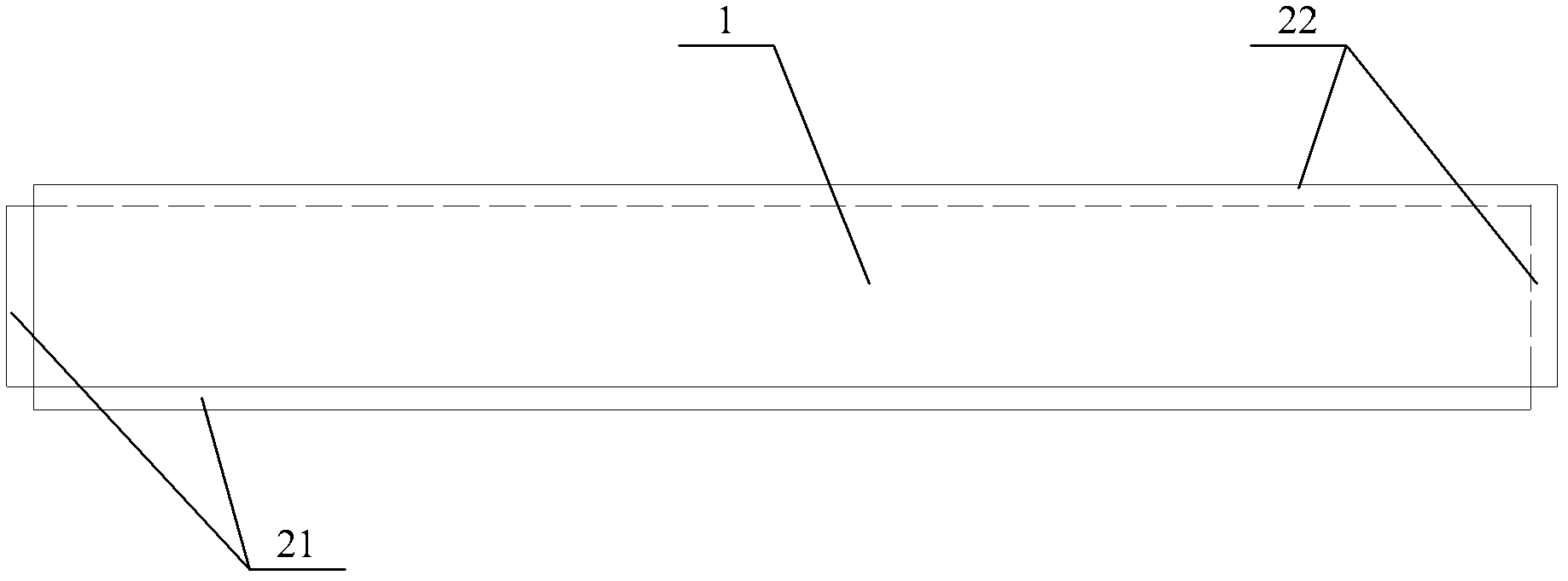

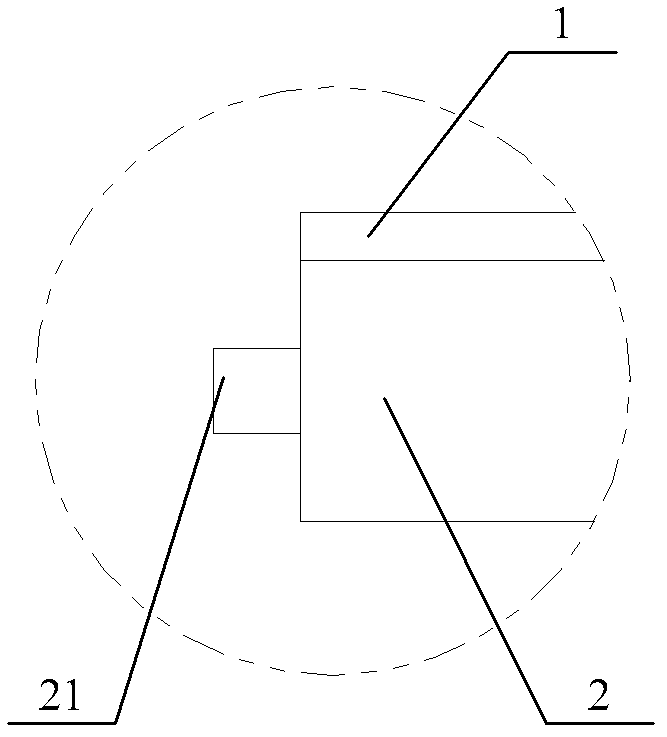

[0026] refer to figure 1 with figure 2 , figure 1 The front view of the composite floor provided by the first embodiment of the present invention; figure 2 for figure 1 Top view of laminate flooring shown.

[0027] Such as figure 1 with figure 2 As shown, the composite floor provided by the first embodiment of the present invention includes a surface plywood 1 and a base plate 2 with a small thermal expansion coefficient. The surface plywood 1 is attached to the base plate 2, and the surface plywood 1 can be bonded to base plate 2.

[0028] There are corresponding protrusions 21 and grooves 22 on the side of the base board 2, and the protrusions 21 and grooves 22 can be fastened with the grooves 22 and protrusions 21 on another composite floor to realize the integration of multiple composite floors. assembled.

[0029] The surface plywood 1 can be a lightweight and beautiful board, such as a solid wood board, artificial leather board, artificial wood veneer or natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com