Anti-precipitant and its preparation method

An anti-precipitation agent and solvent technology, applied in the direction of dyeing, textiles and papermaking, can solve the problems of increasing the complexity of the dyeing process, reducing the dyeing effect of fabrics, easy to produce color spots and color stains, etc., to solve the problems of uneven dyeing, Simple and easy process, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

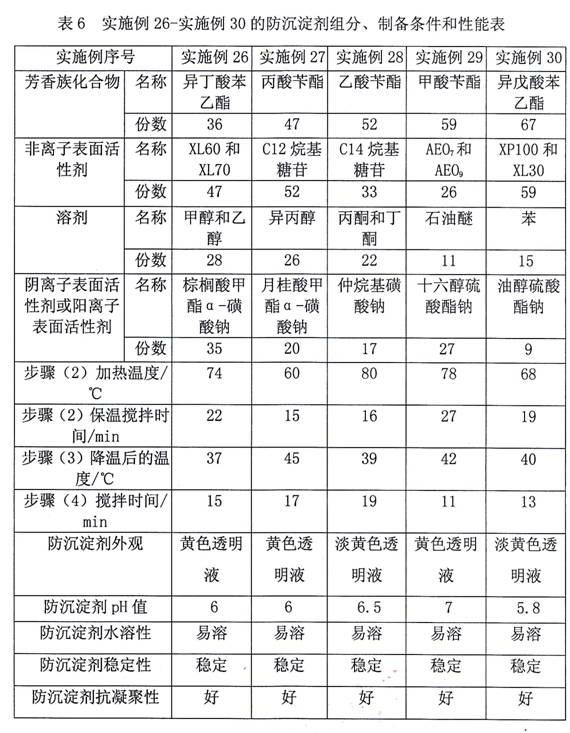

[0019] The anti-precipitation agent in this embodiment includes 30g methyl terephthalate, 25g decanyl alcohol polyoxyethylene ether, 35g sodium lauryl sulfate and 10g isopropanol.

[0020] The preparation method of the anti-sedimentation agent in the present embodiment is as follows: add 30g methyl terephthalate, 25g dedecyl alcohol polyoxyethylene ether and 35g lauryl to the reactor that agitator, thermometer and reflux condensation device are housed Sodium sulfate, then close the reactor and start stirring; heat at the same time, when heated to 60-65°C, keep warm, and stir for 15-20min; then cool down to below 40°C, then add 10g of isopropanol into the reactor and Stir for 10 minutes; then filter and discharge to prepare the anti-sedimentation agent, the performance of the anti-sedimentation agent is shown in Table 1.

[0021] The anti-precipitation agent in this embodiment is mainly used in the same-bath dyeing of anionic dyes and cationic dyes, which can achieve the purpos...

Embodiment 2

[0023] The anti-precipitation agent in the present embodiment includes 40g methylnaphthalene, 25g alkyl glucoside, 20g sodium dodecylbenzenesulfonate and 15g alcohol.

[0024] The preparation method of anti-precipitation agent in the present embodiment is as follows: add 40g methylnaphthalene, 25g alkyl glucoside and 20g sodium dodecylbenzene sulfonate to the reactor that stirrer, thermometer and reflux condensation device are housed, then airtight Reactor and start stirring; heat at the same time, when heated to 60-65°C, keep warm, and stir for 15-20min; then cool down to 40°C, then add 15g of alcohol into the reactor and stir for 10min; then filter and discharge , so as to prepare the anti-precipitation agent, the performance of the anti-precipitation agent is shown in Table 1.

[0025] The anti-precipitation agent in this embodiment is mainly used in the same-bath dyeing of anionic dyes and cationic dyes, which can achieve the purpose of preventing the combination of anioni...

Embodiment 3

[0027] The anti-precipitation agent in this embodiment includes 35g methyl salicylate, 30g alkyl glycoside, 20g quaternary ammonium salt and 15g isopropanol.

[0028] The preparation method of anti-precipitation agent in the present embodiment is as follows: add 35g methyl salicylate, 30g alkyl glucoside and 20g quaternary ammonium salt in the reaction kettle that stirrer, thermometer and reflux condensation device are housed, then airtight reaction kettle and Start stirring; heat at the same time, when heated to 65-70°C, keep warm, and stir for 20-30min; then cool down to 40°C, then add 15g of isopropanol into the reaction kettle and stir for 10min, then filter and discharge, Thereby making anti-sedimentation agent, the performance of this anti-sedimentation agent is shown in Table 1.

[0029] The anti-precipitation agent in this embodiment is mainly used in the same-bath dyeing of anionic dyes and cationic dyes, which can achieve the purpose of preventing the combination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com