Immersion cooling conductive cross arm

A conductive cross-arm and cross-arm technology, applied in electric heating devices, electrical components, heating by discharge, etc., can solve the problems of aluminum's electrical conductivity not as good as copper's, increase processing and manufacturing costs, and complex processing techniques, and achieve a conductive area. Increase, reduce processing cost, overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

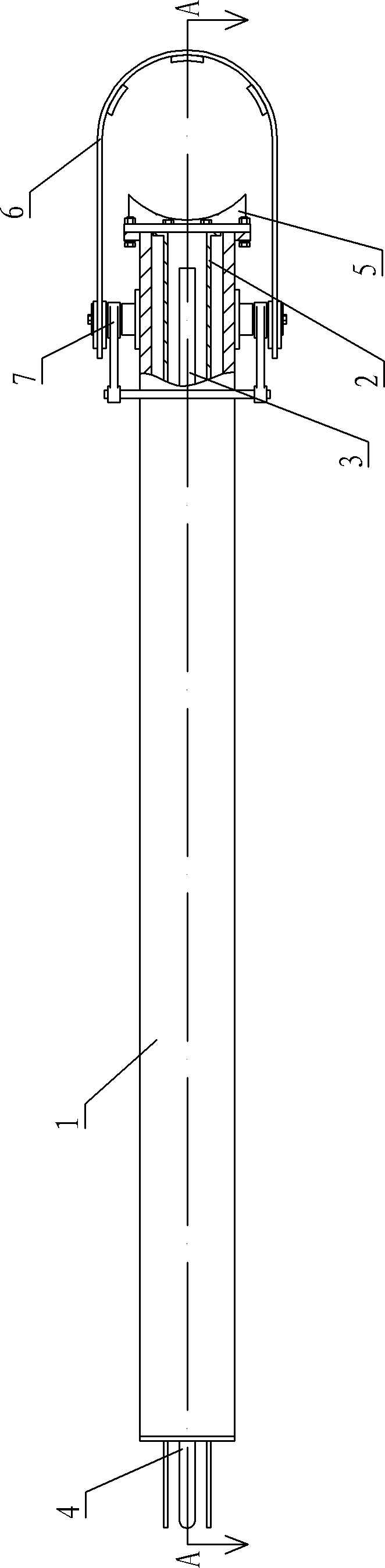

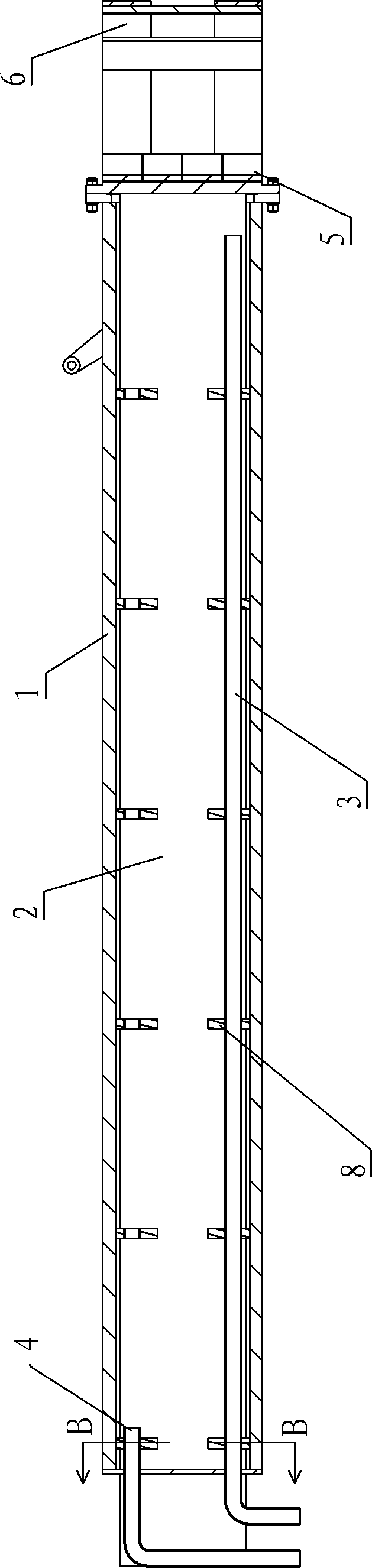

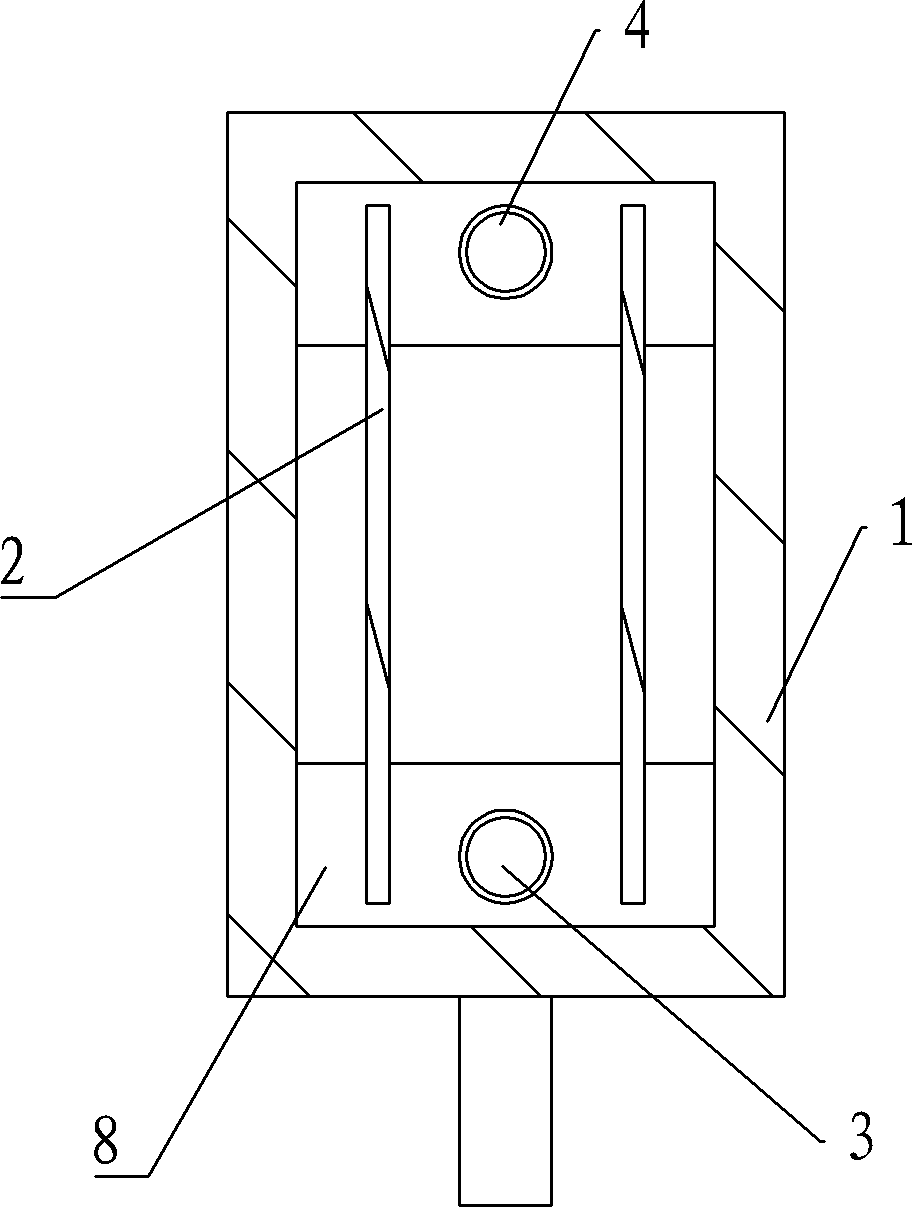

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the immersion-type conductive cross arm of this embodiment includes a steel cross arm main body 1, a conductive copper bar 2, a water inlet pipe 3, a water outlet pipe 4, a conductive chuck 5, an electrode hoop 6, a cam locking mechanism 7, Install fixture 8. The conductive cross arm is installed on the support column through threaded fasteners and a support plate made of insulating material, and rises and falls together with the support column.

[0022] The cross arm main body 1 of the present invention is welded and processed into a rectangular box-type structure, and a copper conductive chuck 5 is installed on the front end of the cross arm main body 1 through bolts and flanges, and the electrode hoop 6 is installed on the cross arm through a cam locking mechanism 7 The front part of the arm main body 1 and the electrode hoop 6 are made of stainless steel. The electrodes (not shown) are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com