Connecting joint of steel pipe concrete column and profile steel concrete beam

A technology for concrete-filled steel tubular columns and concrete beams, which is applied in construction and building construction, etc., can solve problems such as long construction period, inability to construct, and steel bars collide, and achieve simple construction, increase in total material costs, and increase in the cost of peripheral steel pipes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

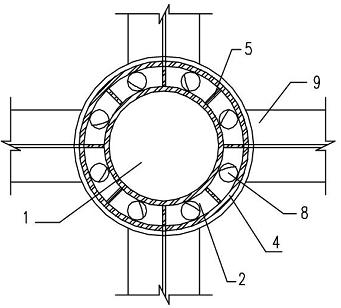

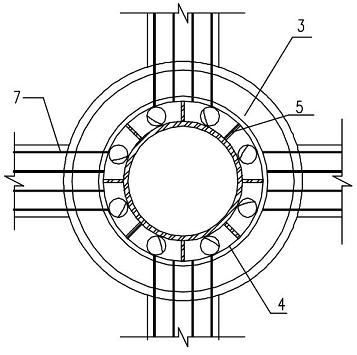

[0013] A connection node between a steel pipe concrete column and a steel concrete beam. A pair of large and small ring plates 3 and 2 with different diameters are arranged at the intersection of the inner steel pipe 1 of the steel pipe concrete column 10 and the steel beam flange 6 in the steel concrete beam 9. The two ring plates 2 and 3 are horizontally and vertically staggered. In order to avoid damage to the section of the steel concrete column 10 caused by opening a large number of steel holes on the steel pipe 1 in the steel pipe concrete column 10, the small ring plate 2 and the steel The steel beam flange 6 in the concrete beam 9 is welded, the large ring plate 3 is welded with the beam internal longitudinal reinforcement 7 in the steel concrete beam 9, and a steel pipe 4 is arranged between the ring plates 2 and 3 to connect the large and small ring plates 3 , 2 welded together as a whole, for further reinforcement, the steel pipe 1 in the column of the concrete-fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com