Glass fiber reinforced plastic shield assembly of road roller

A technology of glass fiber reinforced plastics and road rollers, applied in roads, roads, road repairs, etc., can solve the problems of poor rigidity of glass fiber reinforced plastics, inconvenient maintenance of road rollers, poor overall effect, etc., to overcome the shortcomings of low shear strength, light weight, and improve The effect of connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

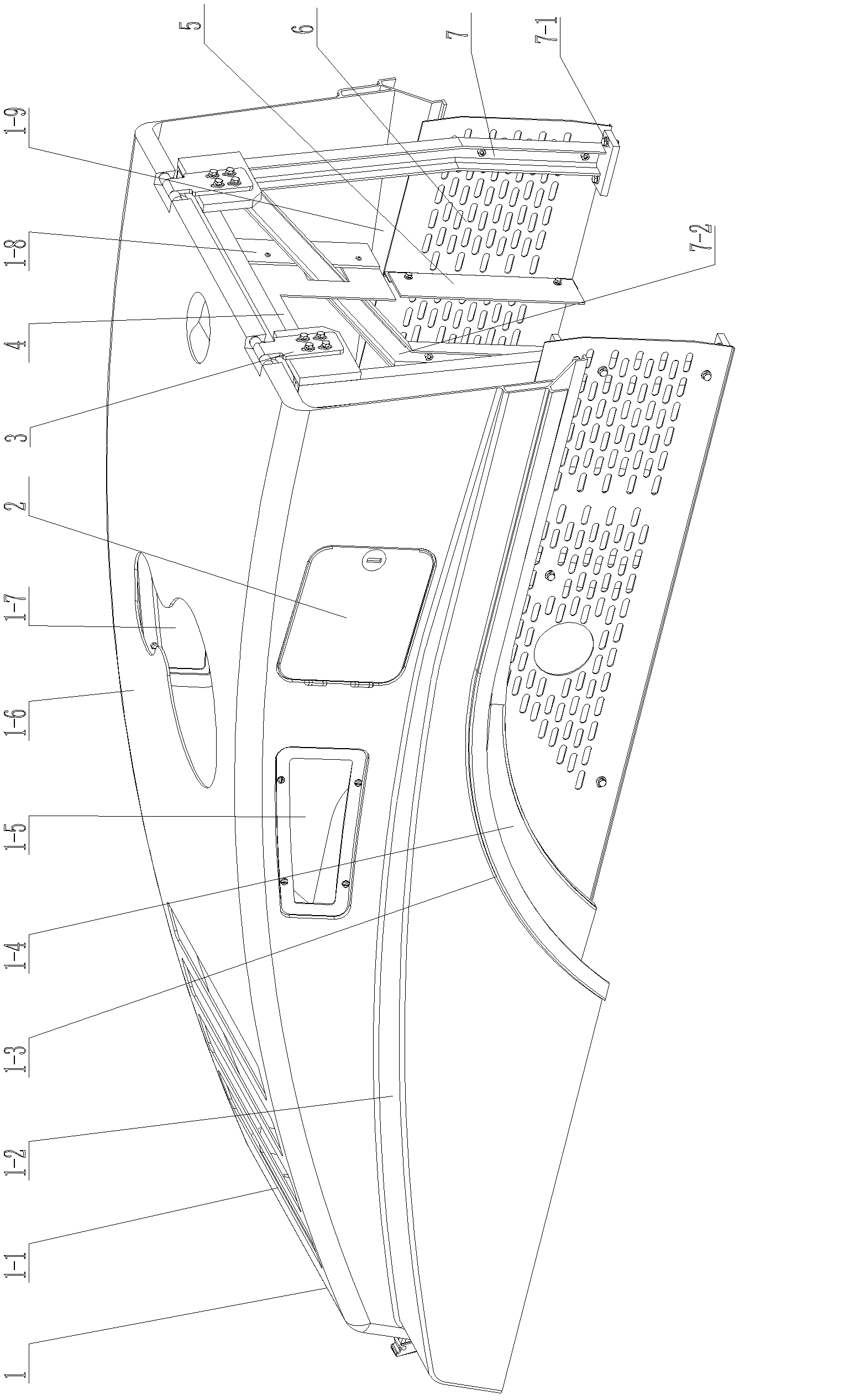

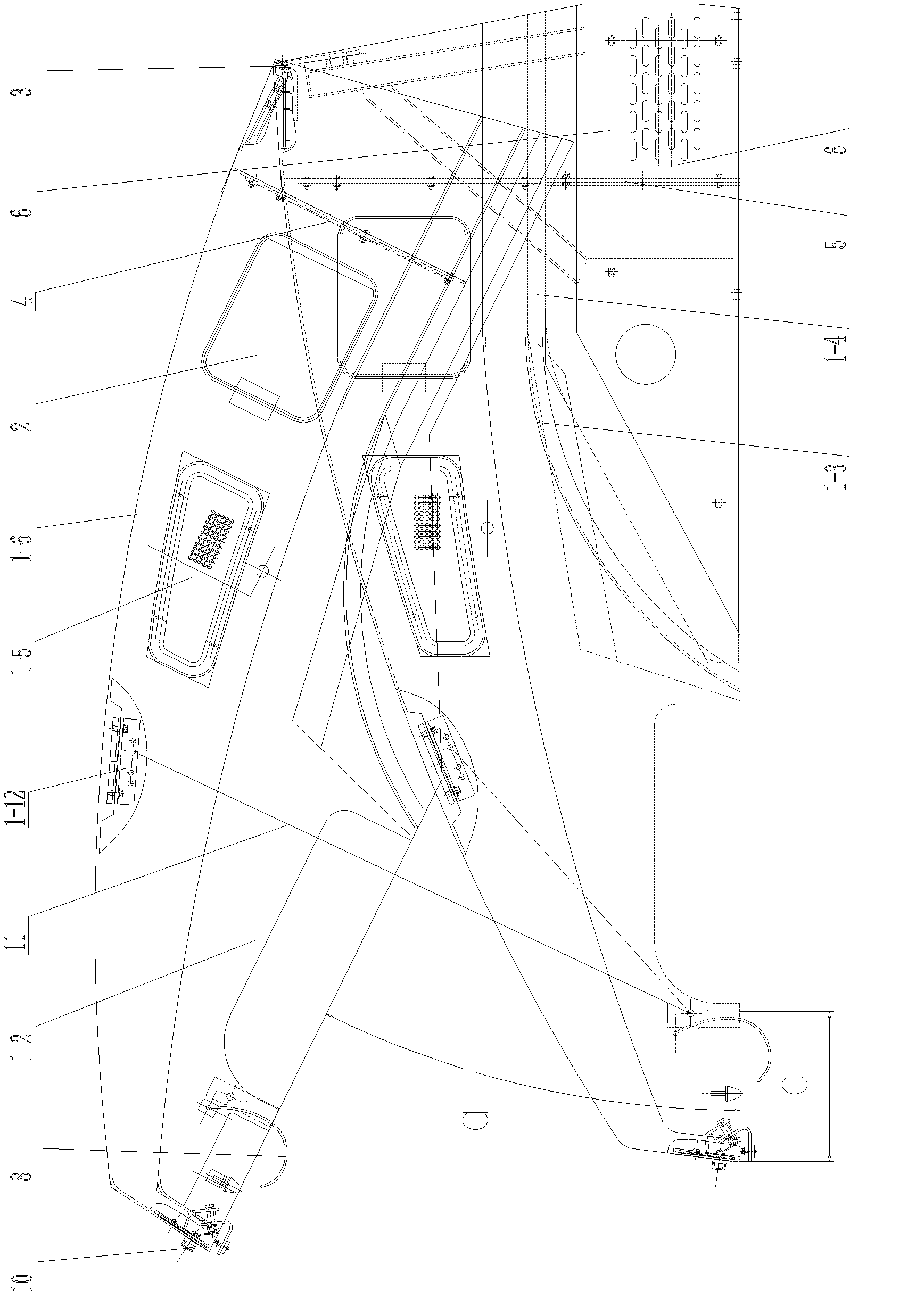

[0014] See Figure 1~5 As shown, the road roller FRP shield assembly of the present invention includes a metal bracket 7, two metal side plates 6 with cooling holes, at least one gas spring 11 and a FRP shield 1 embedded with horizontal and vertical metal skeletons.

[0015] See Figure 1~5 As shown, the FRP shield 1 of the present invention includes a top plate 1-6, side plates 1-2 with stepped sides on both sides, and an inner fender 1-4 and an outer fender 1 located at the front middle of the side plates 1-2. -3, the FRP shield 1 of the present invention is made of 196-198 high temperature resistant resin, and is made by hand-pasting glass cloth. The FRP shield 1 is embedded with two horizontal and vertical metal skeletons, and the thickness of the FRP shield 1 is 6±1mm, not only can improve the rigidity of the FRP shield, but also light in weight, the present invention has flocking on the inner wall of the FRP shield 1, which can increase the effect of sound insulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com