Purifying process for chymotrypsin

A chymotrypsin and process technology, which is applied in the field of chymotrypsin to achieve the effects of improving drug safety, high purity and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

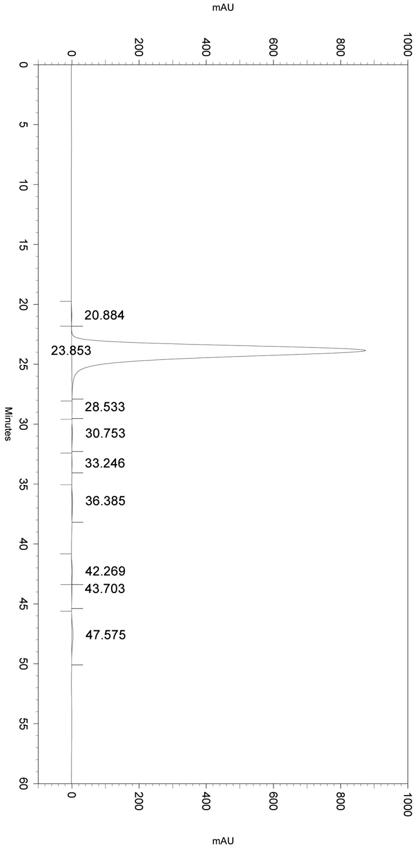

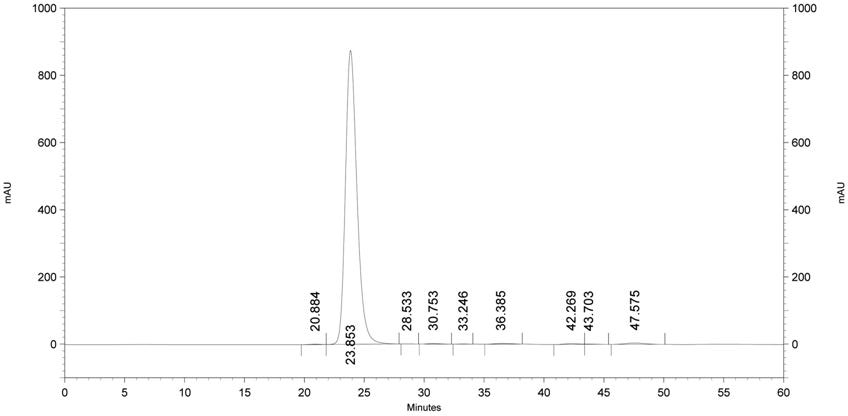

Image

Examples

Embodiment 1

[0031] (1) Take 10 kg of fresh bovine pancreas, remove fat, connective tissue, etc., and grind it into pancreas pulp with a meat grinder;

[0032] (2) Add 20 L (twice the volume of pancreas pulp) 0.25 N sulfuric acid solution, stir and extract in a cold room for 24 hours, filter, filter cake with 10 L of cold 0.25 N sulfuric acid, stir and extract for 1 hour in the same way, filter, and combine twice the filtrate;

[0033] (3) Stir the filtrate and gradually add ammonium sulfate to 0.4 saturation, and place it in a cold room at low temperature overnight;

[0034] (4) Filtration, the filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 50kDa, and the filtrate is collected.

[0035] (5) Perform ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 10kDa;

[0036] (6) Add ammonium sulfate to the filtrate to a saturation of 0.7, and place it overnight at low temperature;

[0037] (7) Collect 390g of filter c...

Embodiment 2

[0044] (1) Take 5kg of frozen bovine pancreas, remove fat, connective tissue, etc., and mince it into pancreas pulp;

[0045] (2) Add 15 L (3 times the volume of pancreatic pulp) 0.25 N sulfuric acid solution, stir and extract in a cold room for 24 hours, filter, and then use cold 0.25 N sulfuric acid solution with 1 times the volume of pancreatic pulp as the filter cake Stir and extract for 1 h, filter, and combine the two filtrates;

[0046] (3) Stir the filtrate and gradually add ammonium sulfate to 0.4 saturation, add diatomaceous earth to aid in filtering, and place it in a cold room at low temperature overnight;

[0047] (4) Filtration, the filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 50kDa;

[0048] (5) The filtrate is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 10kDa;

[0049] (6) Add ammonium sulfate to the filtrate to a saturation of 0.7, place it overnight at low temperature, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com