Epoxy coating and preparation method and application thereof

An epoxy coating and epoxy resin technology, applied in the coating field, can solve the problems of failing to meet the design requirements, shortening the life of the paint film, and high surface treatment costs, achieving low volatile organic compound content, good thick coating, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare epoxy coating according to the following composition and parts by weight,

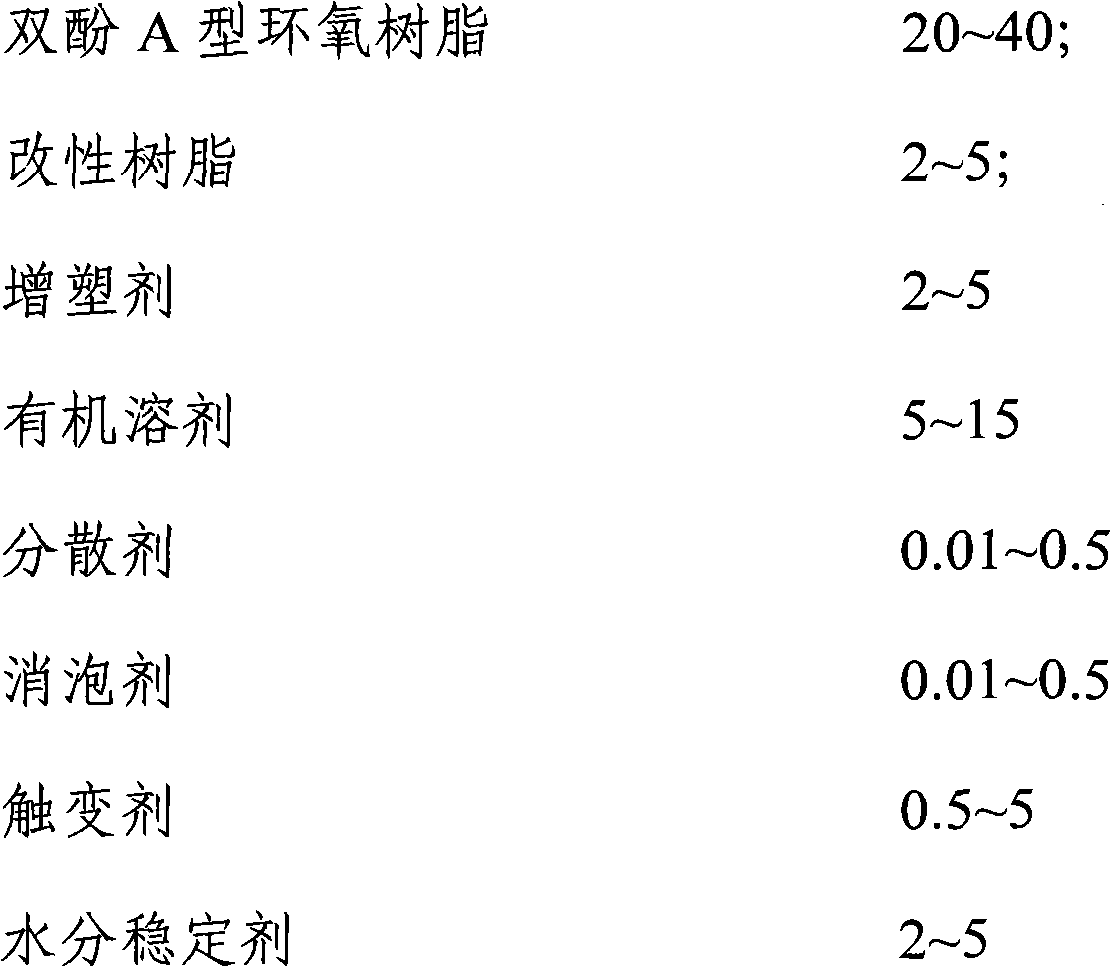

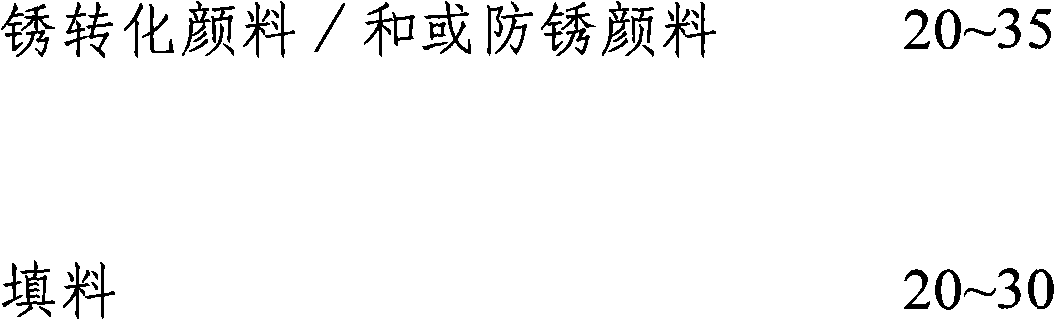

[0030] Main paint:

[0031]

[0032]

[0033] Hardener:

[0034]

[0035] The preparation method of this product is:

[0036] It is characterized by mixing low-molecular-weight bisphenol A epoxy resin DER331, petroleum resin, dibutyl phthalate, xylene, n-butanol, BYK-P104, BYK-052, and bentonite BENTONE 38 and mixing it evenly at high speed. Then add charcoal powder, zinc phosphate, mica iron oxide, aluminum slurry, and talc powder for high-speed dispersion for 0.5-1 hour, and then grind until the fineness meets the requirements, then adjust the product viscosity, and package after it is qualified; the curing agent is separately formulated. When in use, the ratio of the main paint to the curing agent is configured according to the weight ratio of 10:1, and it is used after mixing evenly.

Embodiment 2

[0037] Example 2 Prepare epoxy coating according to the following composition and parts by weight,

[0038] Main paint:

[0039]

[0040] Hardener:

[0041] Polyaminoamide 40

[0042] Cardanol modified phenalkamine 50

[0043] Methyl isobutyl ketone 10

[0044] Total 100

[0045] The preparation method of the high-performance epoxy anticorrosive coating is:

[0046] It is characterized by first combining low molecular weight bisphenol A epoxy resin Epikote 828, K-FLEX 171-90, dibutyl phthalate, xylene, n-butanol, ANTI-TERRA-U, BYK054, DISPARLON 630-20X Mix together at high speed and stir evenly, then add in plaster of paris powder, zinc chromate, mica iron oxide, aluminum slurry, sericite powder, high-speed dispersion for 0.5-1 hours, then grind until the fineness meets the requirements, and then adjust the product viscosity. Pack after qualified; curing agent is separately deployed. When in use, the ratio of the main paint to the curing agent is configured according to the weight ratio...

Embodiment 3

[0047] Example 3 The epoxy coating was prepared according to the following composition and parts by weight.

[0048] Main paint:

[0049]

[0050] Hardener:

[0051] Polyaminoamide 40

[0052] Cardanol modified phenalkamine 40

[0053] Toluene 20

[0054] Total 100

[0055] The preparation method of the high-performance epoxy anticorrosive coating is:

[0056] It is characterized by first mixing low molecular weight bisphenol A epoxy resin NPEL-128, Desmocap 11, dibutyl phthalate, toluene, isopropanol, ANTI-TERRA-U, BYK-051, BYK-430 and high speed Stir evenly, then add plaster of paris powder, zinc oxide, iron oxide mica, aluminum powder slurry, sericite powder, and disperse at high speed for 0.5-1 hours, then grind until the fineness meets the requirements, then adjust the product viscosity, and package after qualified; The curing agent is formulated separately. When in use, the ratio of the main paint to the curing agent is configured according to the weight ratio of 8:1, and it is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com