Method for preparing high-ductility conductive polymer composite material

A conductive polymer and composite material technology, applied in the field of conductive polymer composite material preparation, can solve the problems such as toughness and ductility of isolation structure composite materials that are not consulted, and achieve the effects of easy industrial production operation, excellent impact performance, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The main raw material is composed of the following components by weight percentage: UHMWPE 80%; HDPE 18%; CNT 2%.

[0039] The process steps adopt:

[0040] (1) Drying of raw materials: drying the CNTs in an oven at a constant temperature of 78° C. until the water content by weight is less than 0.01%.

[0041] (2) Preparation of CNT / HDPE conductive masterbatch: The obtained dry CNT and alcohol were formulated into a carbon nanotube alcohol suspension at a mass ratio of 1:50, and then uniform dispersion was achieved by ultrasonic and mechanical stirring for 15 minutes. At the same time, HDPE was dissolved in xylene at a mass ratio of 1:20, stirred, and mixed at 140° C. for 2 hours. Finally, pour the dispersed CNT into the dilute solution of HDPE and xylene to flocculate the CNT / HDPE mixture. Finally, it is vacuum filtered and dried in a vacuum oven at a constant temperature of 60°C until the moisture content is less than 0.01% by weight;

[0042] (3) Pulverization and...

Embodiment 2

[0046] Others are the same as in Example 1, the ratio of raw materials is UHMWPE 99%; HDPE 0.9%; CNT 0.1%, and the drying temperature of CNT is 80°C.

[0047] During the preparation of the CNT / HDPE conductive masterbatch in step (2), CNT and alcohol are dissolved in xylene at a mass ratio of 1:200; HDPE is dissolved in xylene at a mass ratio of 1:40. The drying temperature of the CNT / HDPE mixture is 60°C.

Embodiment 3

[0049] Others are the same as in Example 1, the ratio of raw materials is UHMWPE 89%; HDPE 9.9%; CNT 1.1%. In step (1), the CNT drying temperature is 79°C.

[0050] When preparing the CNT / HDPE conductive masterbatch in step (2), the mass ratio of CNT and alcohol is 1:400; HDPE is dissolved in xylene at a mass ratio of 1:50, and the drying temperature of the CNT / HDPE mixture is 60°C.

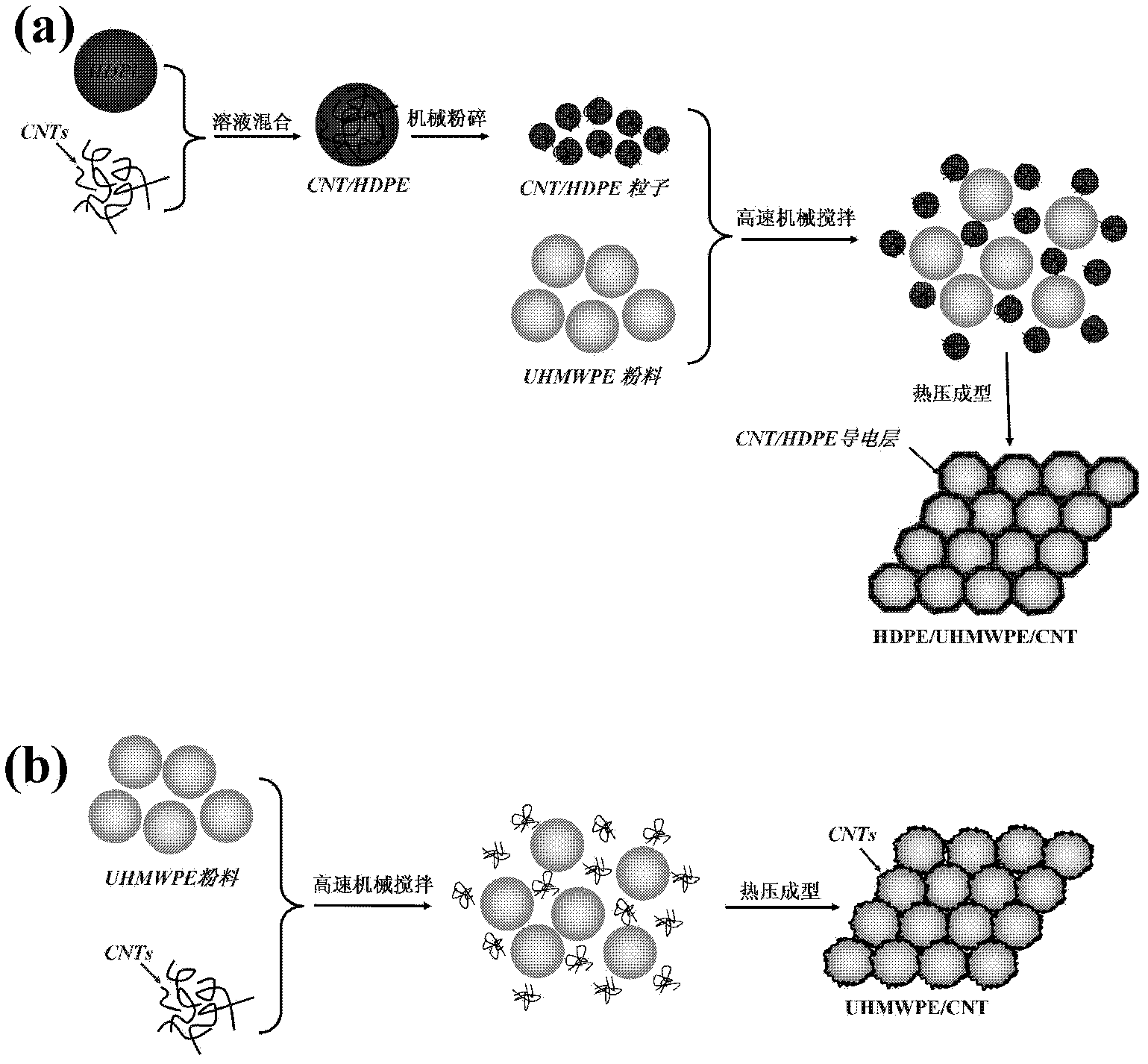

[0051] As a comparative example, the CNT / UHMWPE isolation structure composite material, its process route is as follows figure 1 Shown in (b), its preparation method is:

[0052] (1) Drying of raw materials: drying the CNTs in a vacuum oven at a constant temperature of 78° C. until the water content by weight is less than 0.01%.

[0053] (2) High-speed mixing: The pulverized CNT and dried UHMWPE particles were mixed and stirred at a high speed of 25,000 RPM for 4 minutes in proportion (keep the stirring temperature not exceeding 60°C) to complete the uniform coating of CNT on UHMWPE.

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com