Method for preparing macromolecular composite friction material

A technology of composite friction materials and composite materials, which is applied in the field of preparation of polymer composite friction materials, can solve the problems of high noise, heavy weight, cumbersome installation, etc., and achieve the effect of easy installation, light weight and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

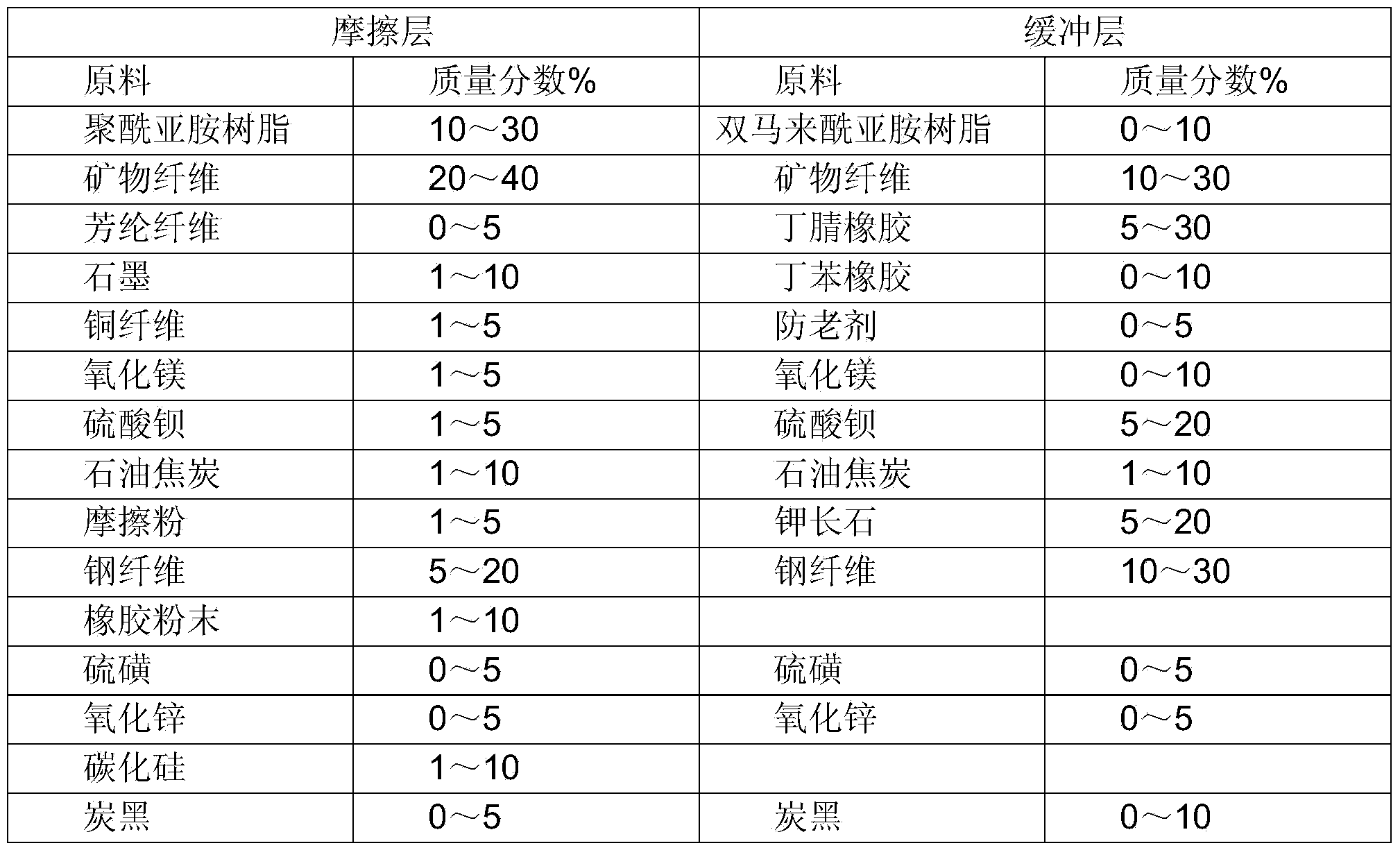

example 1

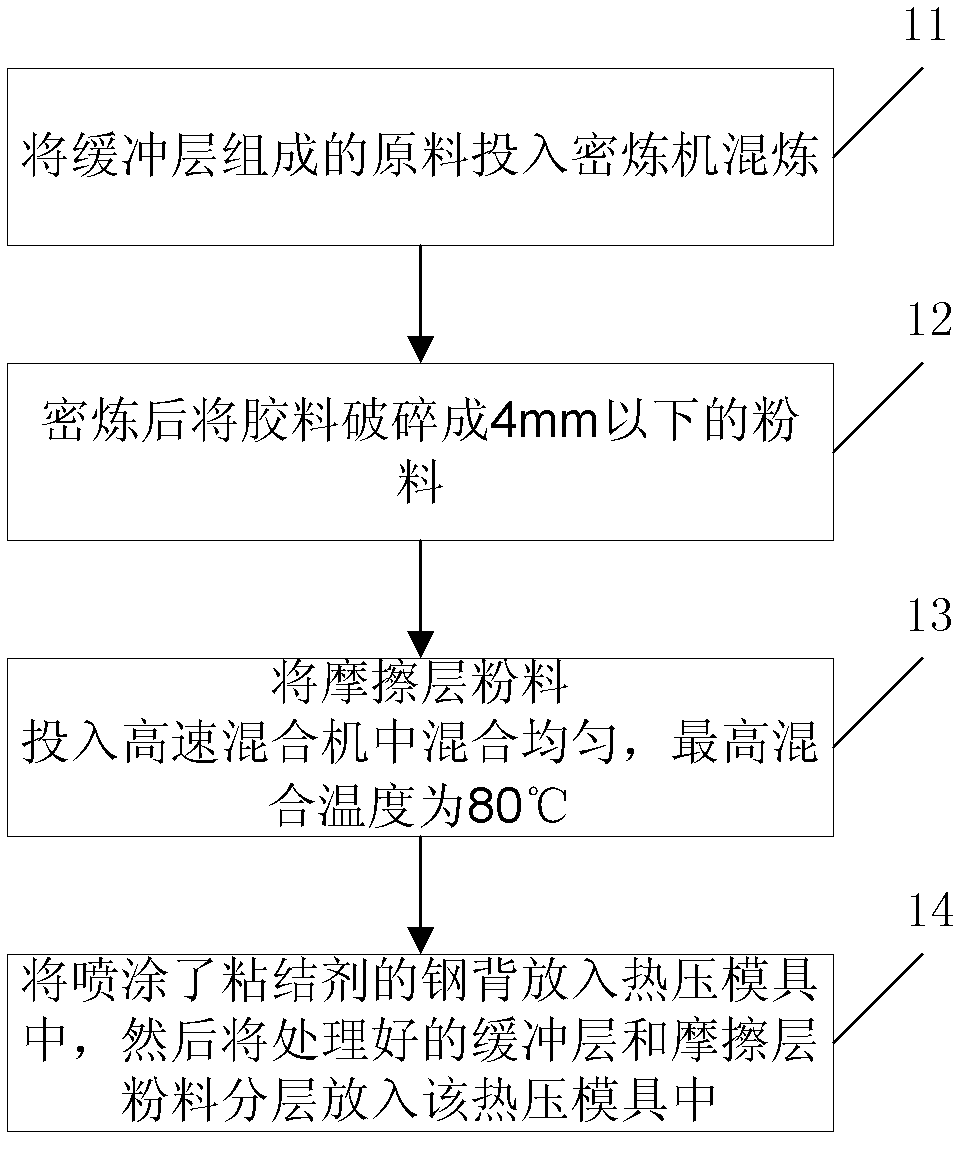

[0032] The specific preparation process is as follows: firstly mix the components of the buffer layer raw materials in the following table 2 in the internal mixer according to the mass ratio, the effective temperature of the internal mixing rubber is controlled between 85°C and 115°C, and the internal mixing time is 6 minutes , After banburying, the rubber material is broken into powder below 4mm.

[0033] Then put the friction layer fabric into a high-speed mixer and mix evenly. The maximum mixing temperature is 80°C. The steel back sprayed with adhesive is put into the mould, and then the treated buffer layer and friction layer powder are layered into the hot pressing mould.

[0034] Among them, the mold temperature is 210°C, the holding pressure is 22MPa, the pre-compressing exhaust pressure is gradually increased to the holding pressure, the number of exhausting is 5 times, the single pre-pressing time is 10s, the exhausting time is 3s, and the hot-pressing holding time is...

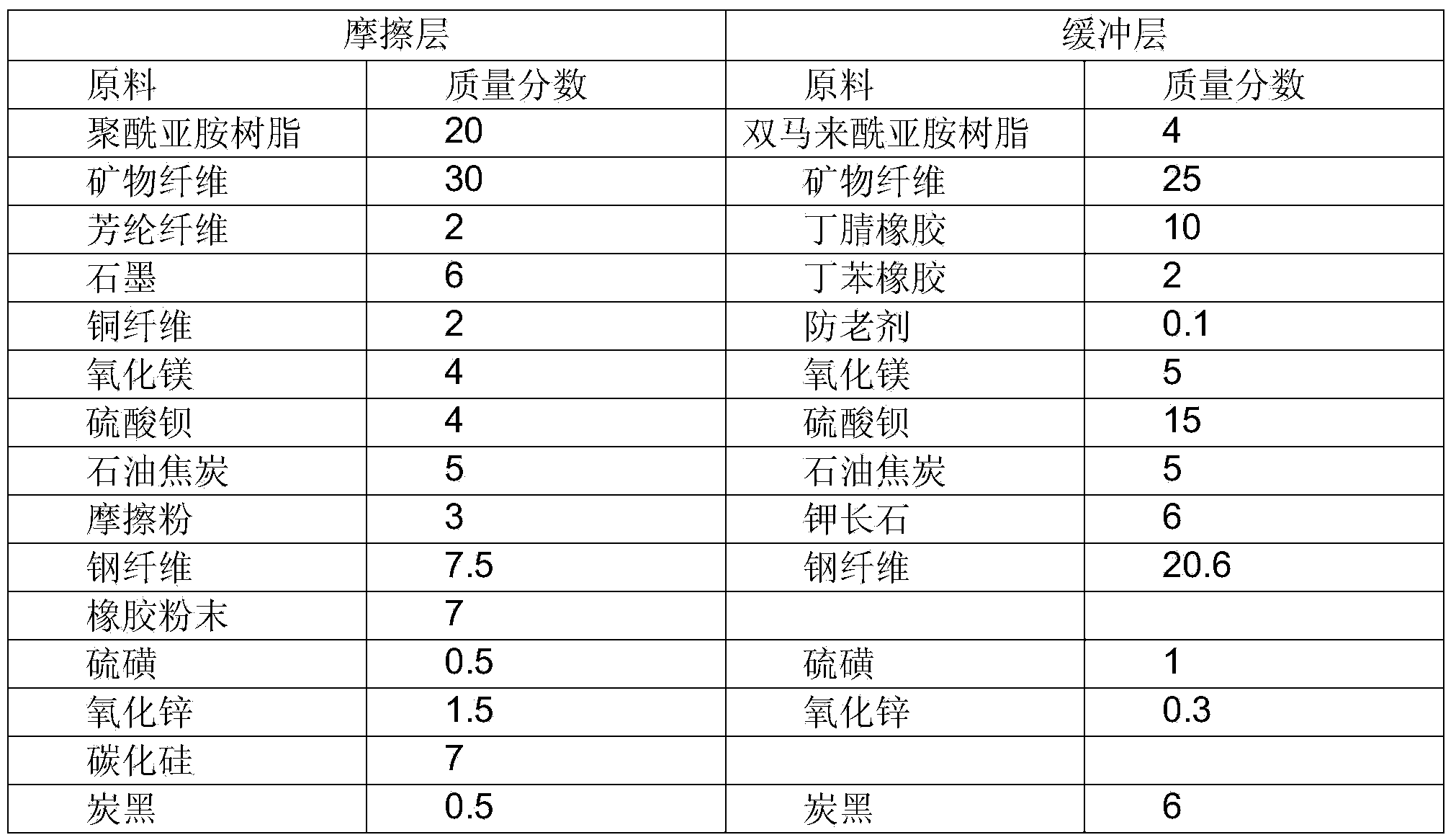

example 2

[0038] The specific preparation process is as follows: first, according to the mass ratio, the components of the buffer layer bottom material in the following table 3 are mixed in the internal mixer, the effective temperature of the internal mixing rubber is controlled between 95 ° C and 115 ° C, and the internal mixing time is 5 Minutes, after banburying, the rubber material is broken into powder below 5mm.

[0039] Then put the friction layer fabric into a high-speed mixer and mix evenly. The maximum mixing temperature is 75°C. The steel back sprayed with adhesive is put into the mould, and then the treated buffer layer and friction layer powder are layered into the hot pressing mould.

[0040] Among them, the mold temperature is 220 ° C, the holding pressure is 20 MPa, the pre-pressing and exhausting pressure is gradually increased to the holding pressure, the number of exhausting is 5 times, the single pre-pressing time is 10s, the exhausting time is 3s, and the hot-pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com