Method for processing L-shaped plate

A processing method and plate technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of large loss of raw materials, large molding allowance, low material yield, etc., to improve efficiency, simple processing method, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

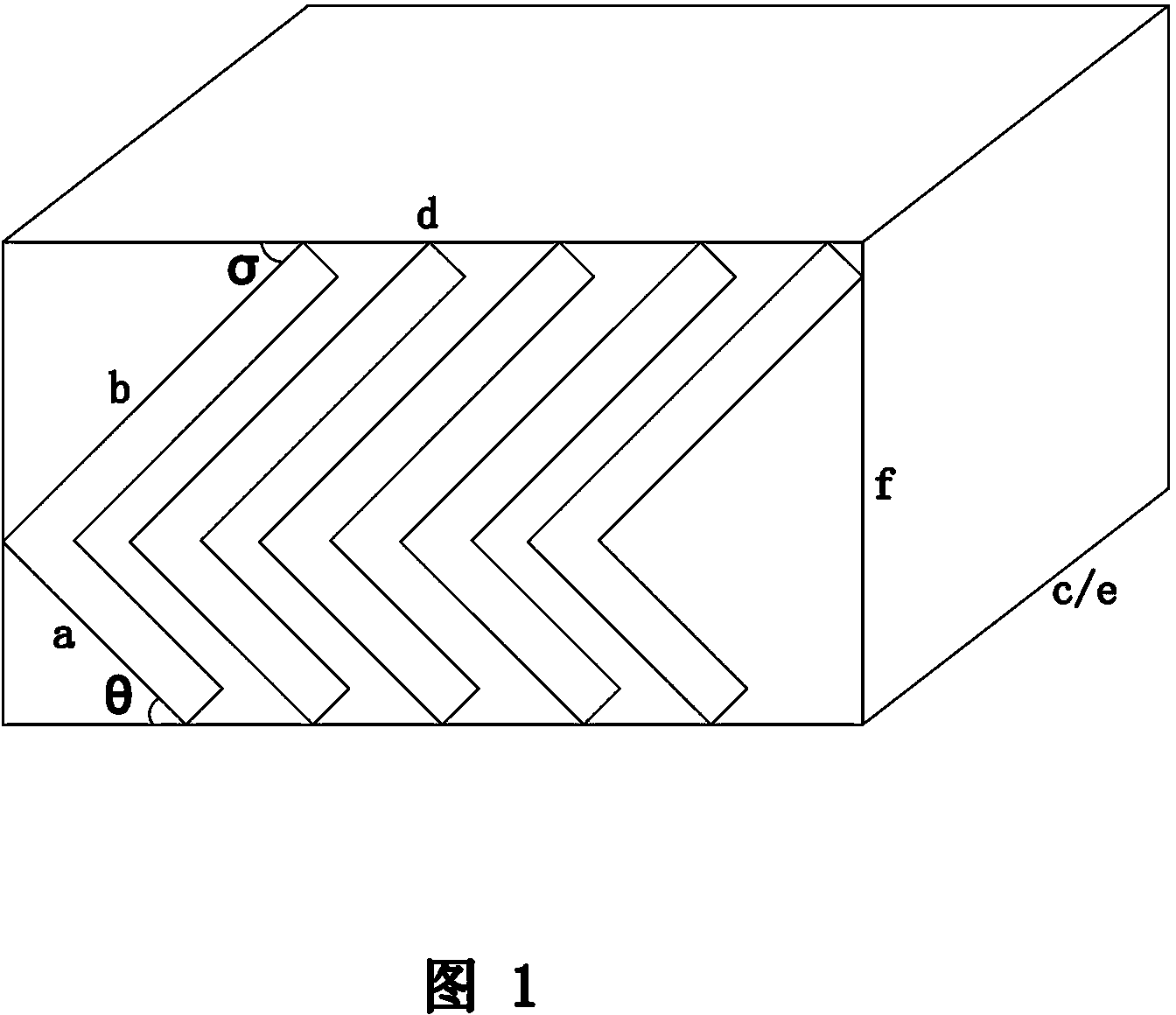

[0019] A kind of processing method of L-shaped plate, refer to figure 1 , including the following steps:

[0020] ①. Determine the length a, b and thickness c of both sides of the L-shaped plate to be processed;

[0021] ②. Select a blank with length d, width e, and height f, where d is greater than or equal to the shorter side of side length a and b, e is greater than or equal to c, and f is greater than or equal to / 2(a+b);

[0022] ③. Draw the lengths a and b of the two sides of the L-shaped plate on the long and high surface with the length d and the height f of the blank, and the length a of the side forms an angle θ with one of the long and high surfaces of the blank, and the length b of the side and the other One length forms a σ angle, and both the θ angle and the σ angle are greater than 0° and less than 90°;

[0023] ④. Programmed by the wire intermediary machine, the L-shaped plate is cut out along the drawn outline of the L-shaped plate and along the width dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com