Foundry used sand wet intermittent regeneration method and equipment thereof

An intermittent, used sand technology, applied in casting and molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure, complex process, and narrow use surface of regeneration equipment, and achieve simple structure, high quality, and water consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

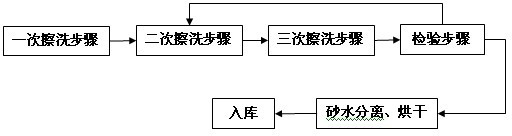

[0038] Embodiment 1: be used for neutral clay old sand regeneration, comprise the steps:

[0039] (1) One-time scrubbing step: according to the mass ratio of 1:0.5, add old sand and clean water into the scrubbing cylinder respectively for stirring and scrubbing, stirring and scrubbing for 30 seconds, and then discharge the sewage in the scrubbing cylinder;

[0040] (2) Second scrubbing step: inject clean water into the scrubbing cylinder again, the mass ratio of old sand and clean water in the scrubbing cylinder is 1:0.5, perform agitation and scrubbing for 30 seconds, and then discharge the sewage in the scrubbing cylinder;

[0041] (3) Three scrubbing steps: inject clean water into the scrubbing cylinder for the third time, the mass ratio of the old sand and clean water in the scrubbing cylinder is 1:0.5, stir and scrub for 30 seconds, and then discharge the sand-water mixture in the scrubbing cylinder into the sand Water separation equipment for separation;

[0042] (4) In...

Embodiment 2

[0044] Embodiment 2: be used for neutral clay old sand regeneration, comprise the steps:

[0045] (1) One-time scrubbing step: according to the mass ratio of 1:3, add old sand and clean water into the scrubbing cylinder respectively for stirring and scrubbing, stirring and scrubbing for 300 seconds, and then discharge the sewage in the scrubbing cylinder;

[0046] (2) Second scrubbing step: inject clean water into the scrubbing cylinder again, the mass ratio of old sand and clean water in the scrubbing cylinder is 1:3, perform stirring and scrubbing, and the stirring and scrubbing time is 300 seconds, and then discharge the sewage in the scrubbing cylinder;

[0047] (3) Three scrubbing steps: inject clean water into the scrubbing cylinder for the third time, the mass ratio of the old sand and clean water in the scrubbing cylinder is 1:3, perform agitation and scrubbing, the stirring and scrubbing time is 300 seconds, and then discharge the sand-water mixture in the scrubbing cy...

Embodiment 3

[0050] Embodiment 3: be used for the old sand regeneration of alkaline water glass, comprise the steps:

[0051] (1) One-time scrubbing step: according to the mass ratio of 1:0.5, add the old sand and clean water into the scrubbing cylinder respectively for stirring for 30 seconds, and then discharge the sewage in the scrubbing cylinder;

[0052] (2) Second scrubbing step: inject clear water into the scrubbing cylinder again, the mass ratio of old sand and clean water in the scrubbing cylinder is 1:0.5, and add hydrochloric acid, stir for 30 seconds, and then discharge the sewage in the scrubbing cylinder; When the concentration of hydrochloric acid is 37.5% by mass, the amount added is 0.8ml hydrochloric acid per kg of old sand;

[0053] (3) Three scrubbing steps: inject clean water into the scrubbing cylinder for the third time, the mass ratio of old sand and clean water in the scrubbing cylinder is 1:0.5, stir for 30 seconds, and then discharge the sand-water mixture in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com