Device and method for desulfuration, denitration and demercuration by using microwave induction and catalysis jointly

A technology for desulfurization, denitrification, mercury removal, and induced catalysis is applied in the field of comprehensive flue gas treatment of coal-fired power plants, which can solve the problems of low energy utilization rate, low combined removal efficiency, large equipment space, and save equipment investment and space. , The effect of high combined removal efficiency and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

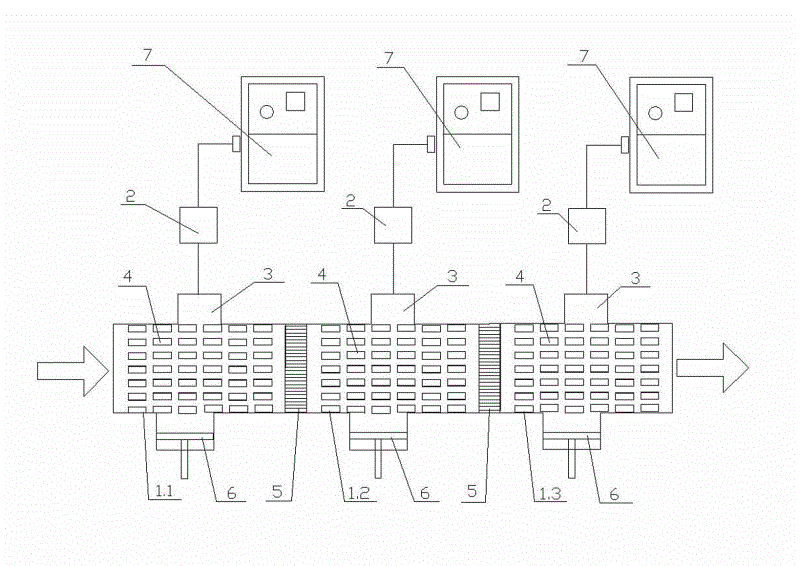

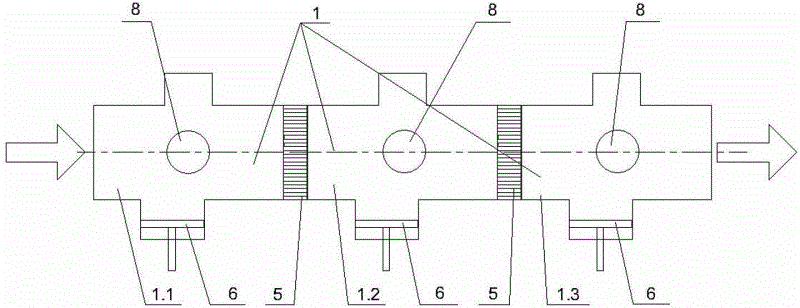

[0026] Please refer to figure 1 with figure 2 As shown, the microwave-induced catalytic combined desulfurization, denitration and demercuration device of the present invention includes a reactor 1 and a microwave transmission and control device 2, and it also includes at least three single-mode microwave sources 7. In the reactor 1, at least There are three reaction chambers with microwave feeding ports 3, each of the reaction chambers communicates with the single-mode microwave source 7 through the microwave transmission and control device 2 respectively; Short-circuit piston 6 with microwave feeding port 3 opposite to each other, and a partition 5 is provided between the reaction chambers for the smooth passage of flue gas and can effectively prevent the mutual interference of single-mode microwaves in adjacent reaction chambers; Catalysts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com