Egg beater

An egg liquid and gear technology, applied in the field of egg beaters, can solve the problems of low stirring efficiency, difficult to guarantee stirring effect, and difficult to meet supply tasks, etc., and achieve the effect of full and efficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

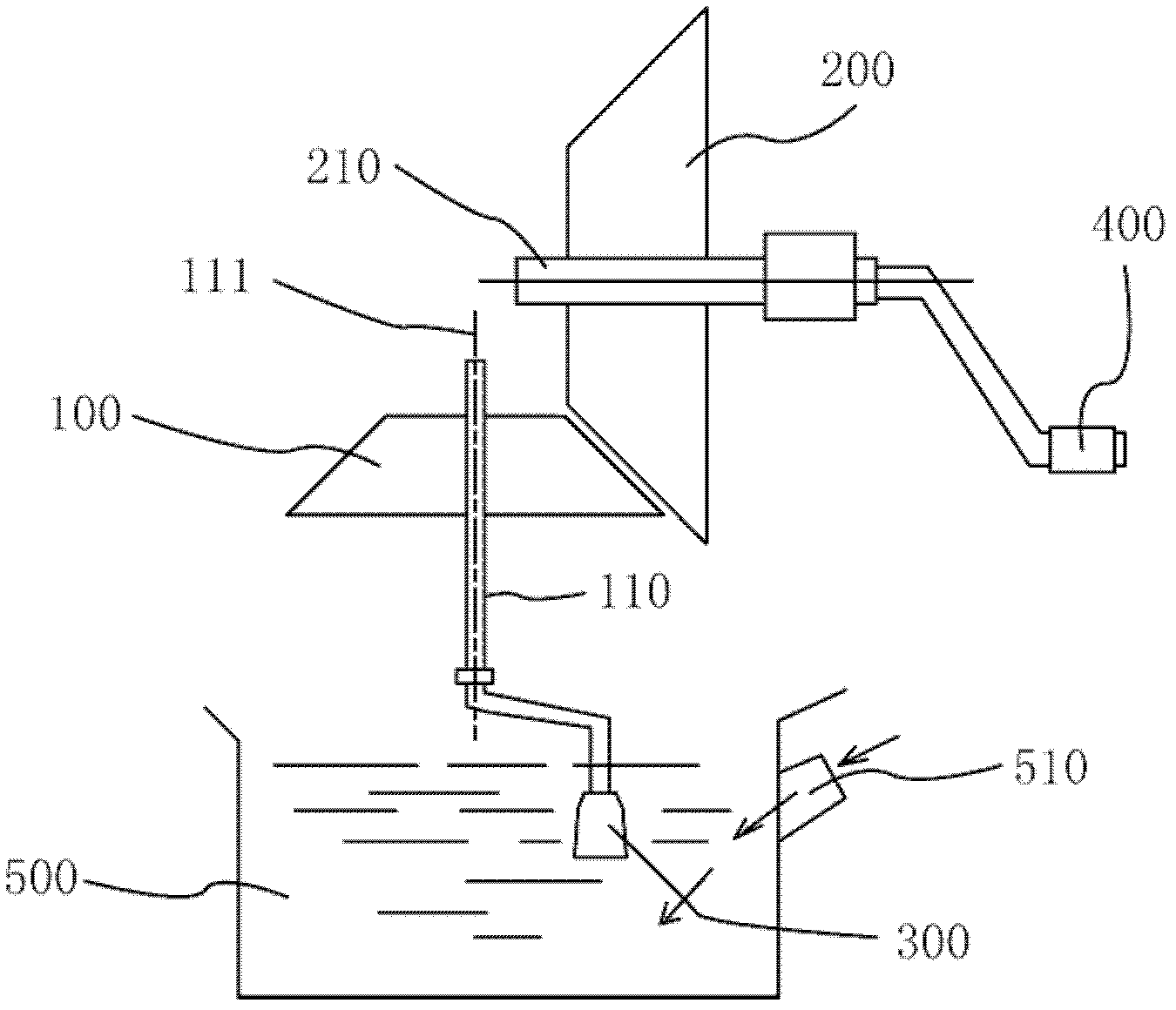

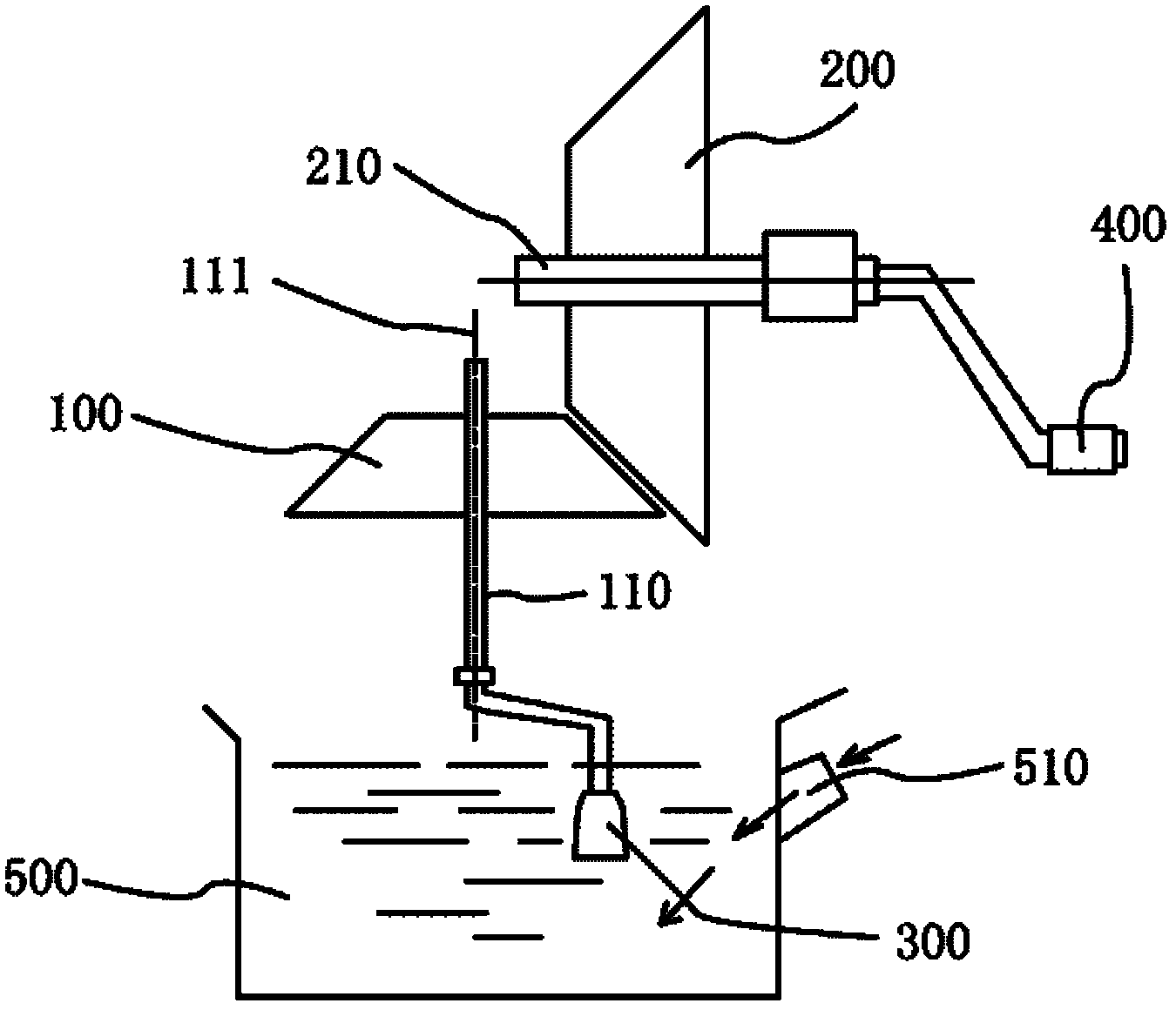

[0014] Such as figure 1 As shown, a group of 45-degree bevel gears 100 and 200 mesh with each other, and the number of teeth of the two is not equal; the rotating shaft 210 of the bevel gear 200 is connected to an L-shaped rocker handle 400, and by shaking the rocker handle 400, the bevel gear 200 realizes rapid rotation, and then Drive the rotation of the bevel gear 100 meshed with it.

[0015] The shaft 110 of the bevel gear 100 is connected to a rod body with a stirring head 300, wherein the position of the stirring head 300 deviates from the axis 111 of the rotating shaft 110, so that when the rotating shaft 110 rotates, the stirring head 300 can stir more significantly; 300 is inserted into the egg liquid holding container 500, and the side of the container has a liquid inlet 510.

[0016] Through the rapid stirring of the stirring head 300, the egg liquid stored in the container 500 is stirred evenly, which facilitates subsequent food or dish preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com