Quick cooling and dehumidifying system for continuous food chilling or quick-freezing process

A processing, cooling and dehumidification technology, applied in the field of food processing, can solve the problems of reduced efficiency, frequent evaporator frosting, power consumption, water consumption, etc., achieve energy saving and efficiency enhancement, obvious dehumidification effect, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to better understand the present invention, it will be further described in detail below with reference to the accompanying drawings and embodiments.

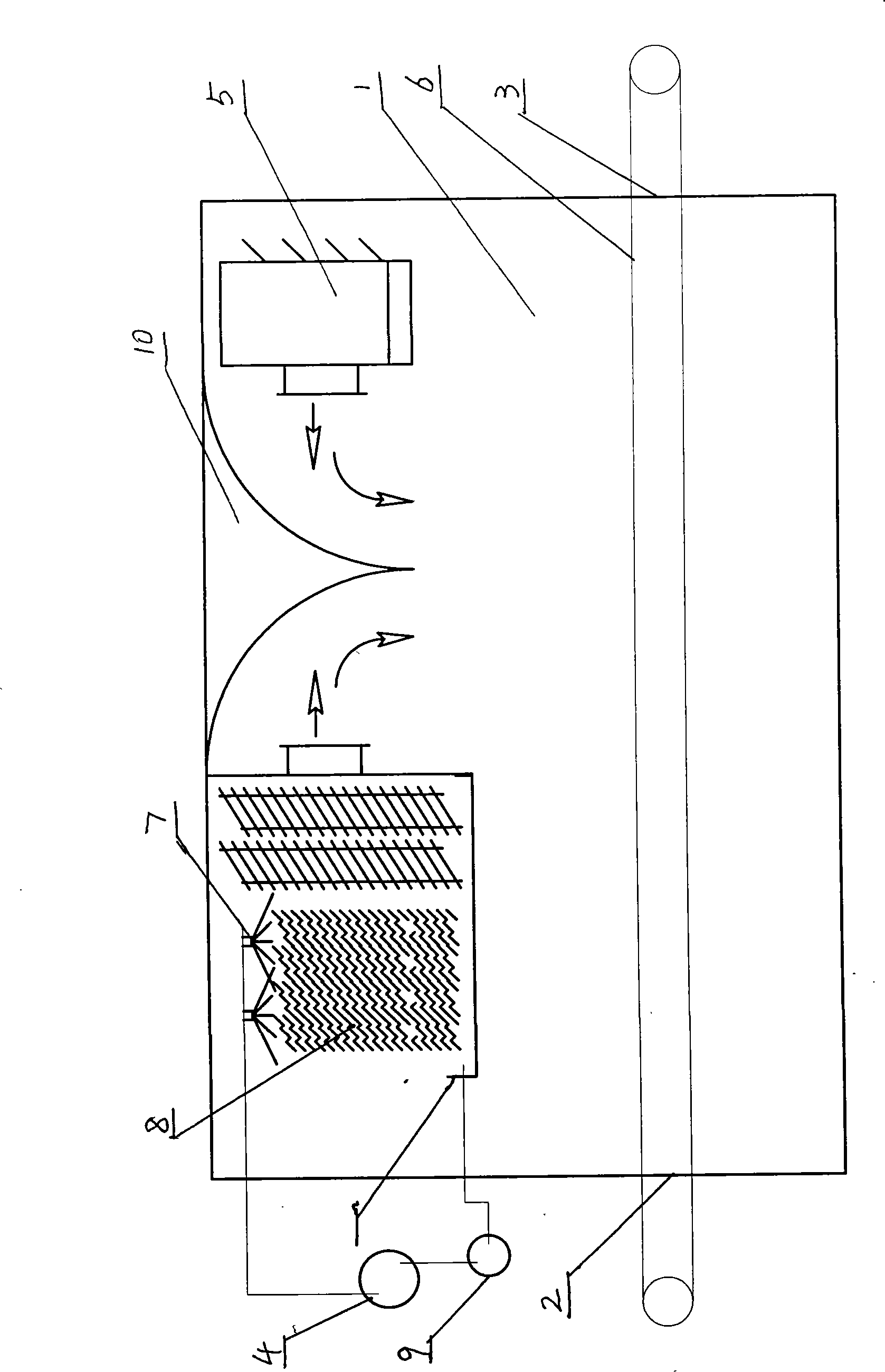

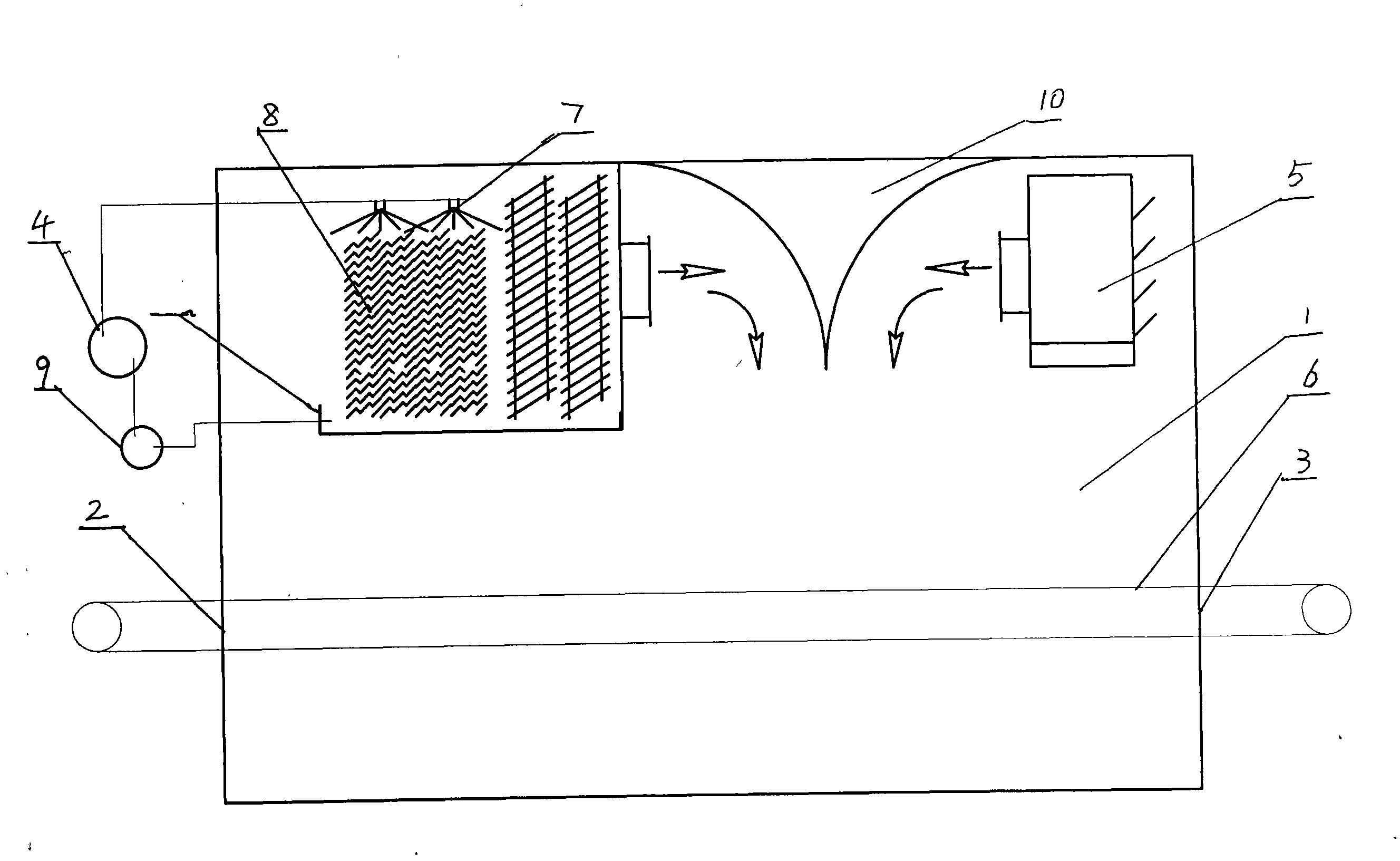

[0009] Such as figure 1 As shown, the rapid cooling and dehumidification system in the continuous cold fresh or quick-freezing process of food of the present invention mainly includes a processing room 1 with an inlet 2 and an outlet 3, and an air-cooled evaporator 5 is installed in the processing room 1. A transmission device 6 for continuously conveying food is installed between the inlet 2 and the outlet 3. A spray device 7 connected to the external water pump 9 and the heat exchanger 4 is installed above the transmission device at the inlet, and low-temperature water or low-temperature brine is used as spray For spraying liquid, the spraying device 7 is equipped with packing 8 to increase the contact area between air and spraying water. There is a water receiving box 11 under the spraying device, and a deflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com