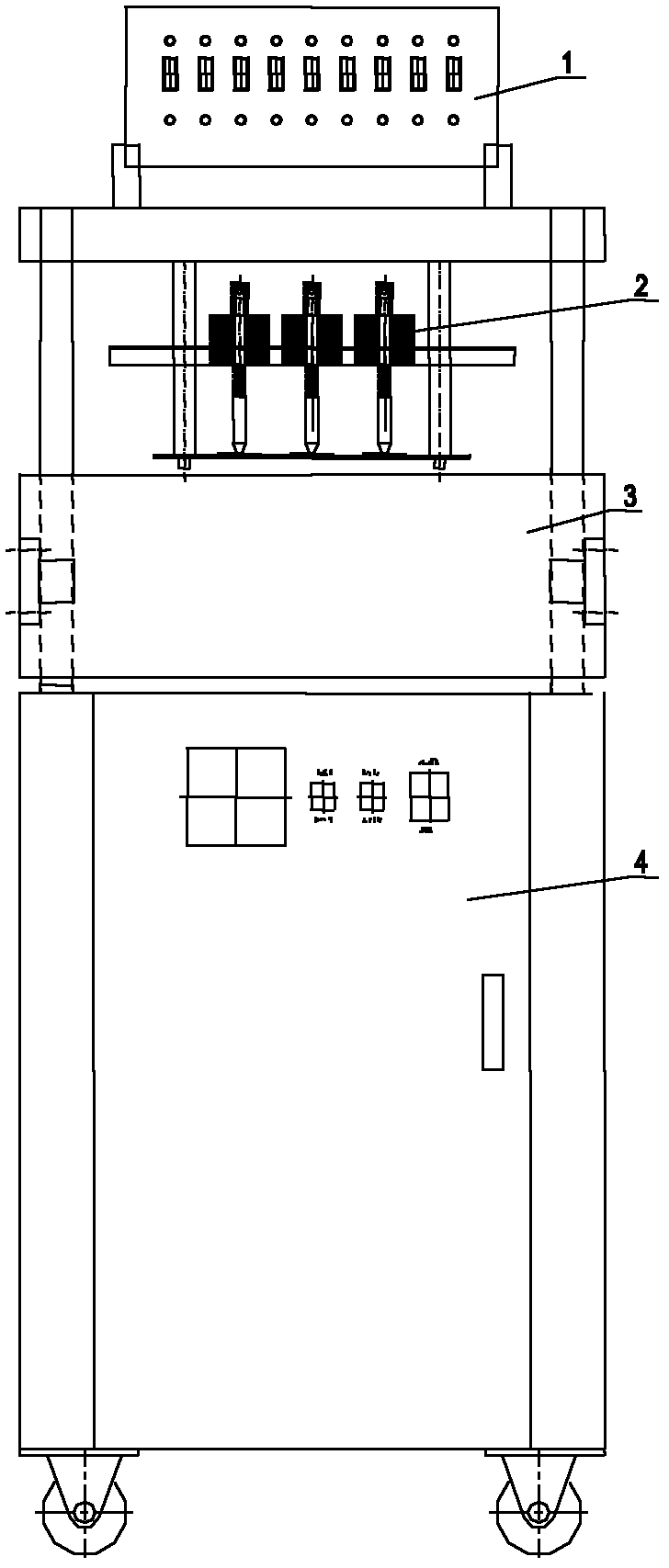

Piezoelectric polarization device and method

A piezoelectric and polarized electrode technology, applied in the direction of circuits, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problem of large polarization and achieve the effect of avoiding unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

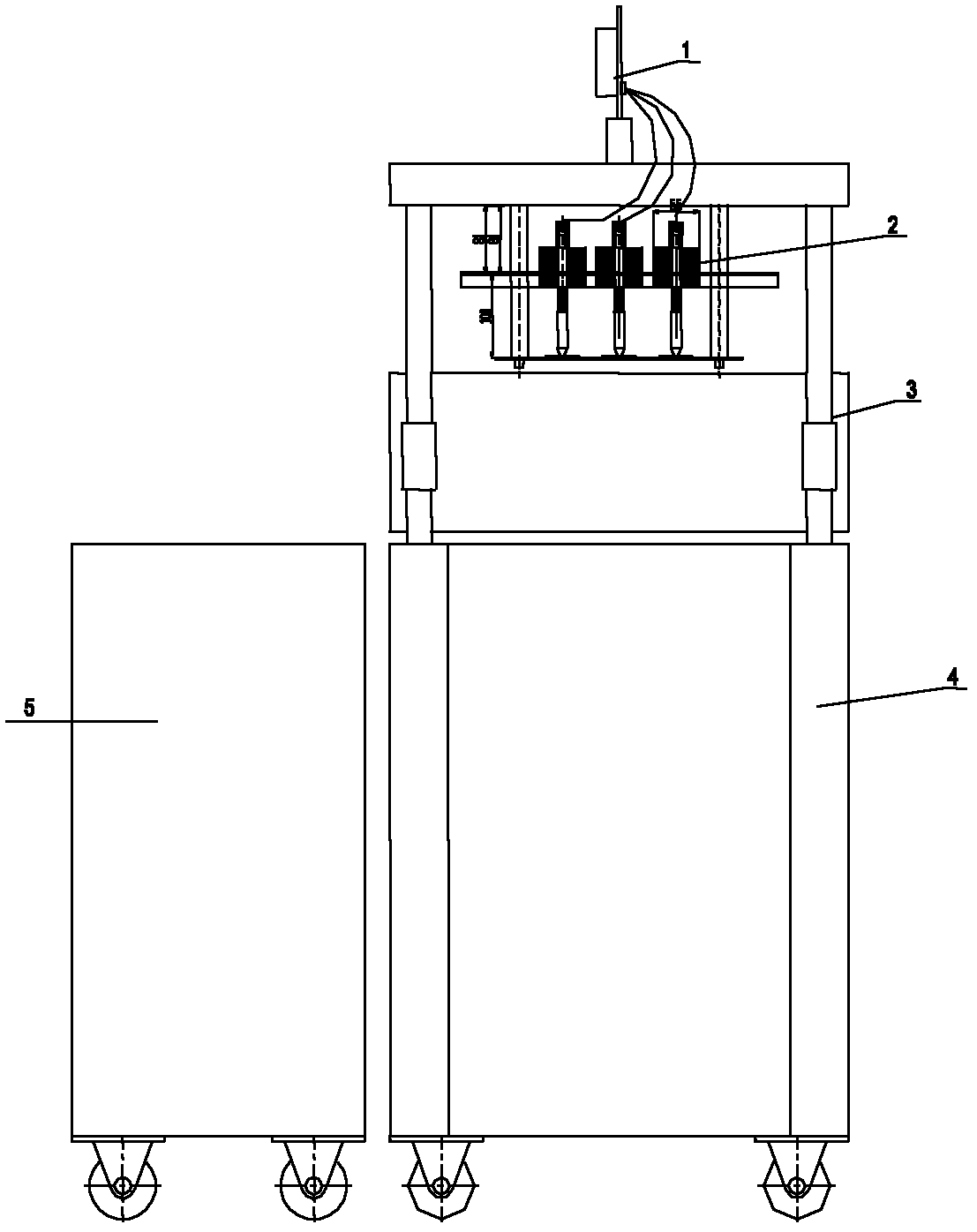

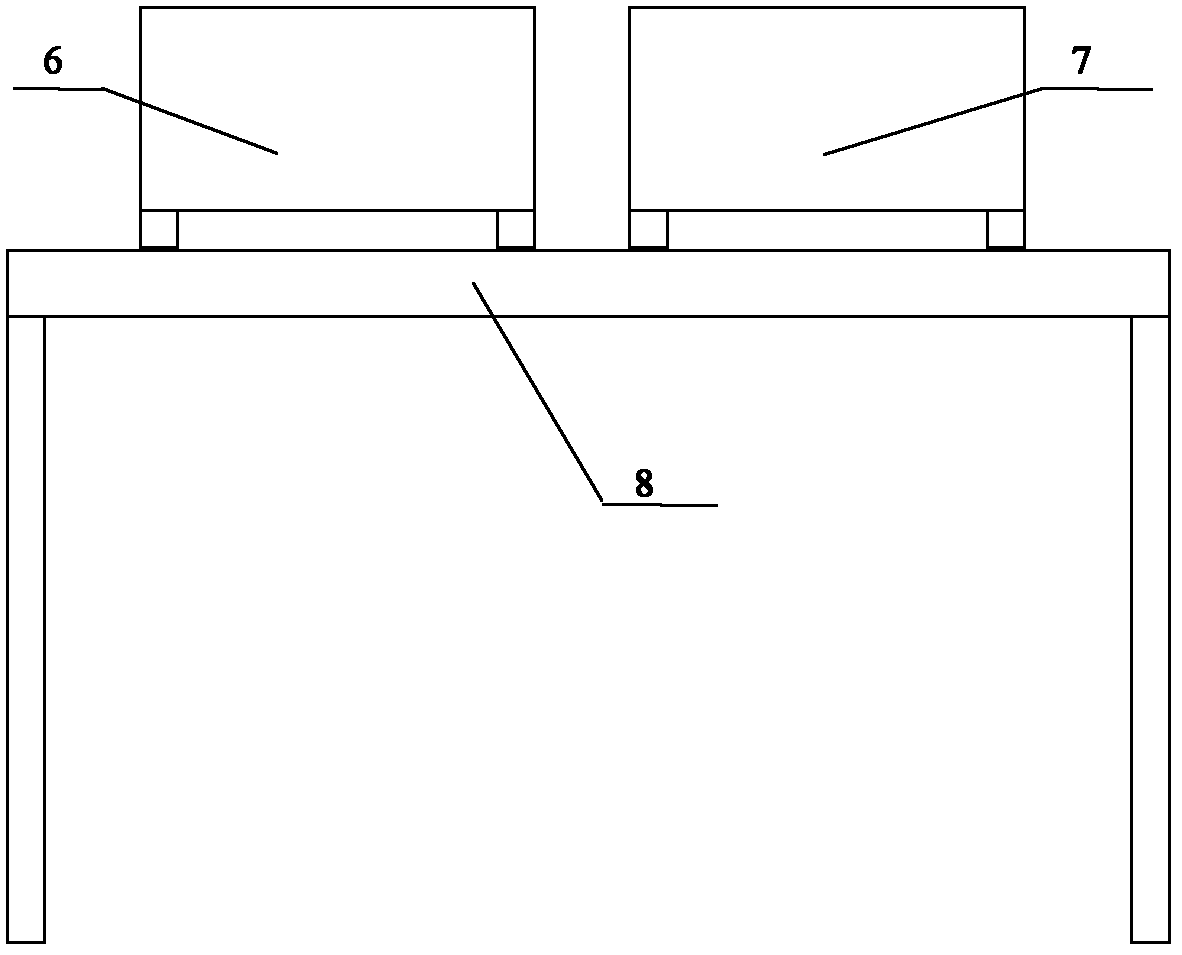

Embodiment Construction

[0022] First, add silicone oil into the polarizing oil tank 3, then put 9 samples into the fixture at the same time, and control the polarizing oil tank 3 with a motor, so that all the fixtures with the test pieces are immersed in the silicone oil. At this time, the operator leaves the polarization host, and operates the remote high-voltage controller 6 and remote polarization controller 7 according to the requirements of the polarization process at a safe distance from the host: connect the high-voltage power supply, set the heating temperature of the polarization oil tank 3, Start the heating switch, the silicone oil starts to heat up, adjust the polarization voltage and polarization time, and carry out the polarization process. After the process is completed, there is no need for complete cooling of the silicone oil, and the motor can be controlled by the remote polarization controller 7 immediately to separate the fixture from the polarization oil tank 3, so that the test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com