Large-scale piping testing apparatus capable of simulating overburden pressure of soil and testing method using large-scale piping testing apparatus

A test device and pressure technology, which is applied in the field of large-scale piping test devices, can solve the problems of large-scale effects, the inability to comprehensively and objectively reveal the development mechanism of piping, and the inability to consider the influence of soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

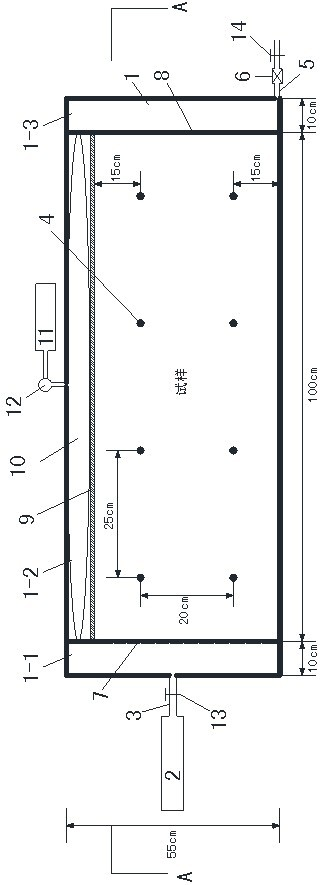

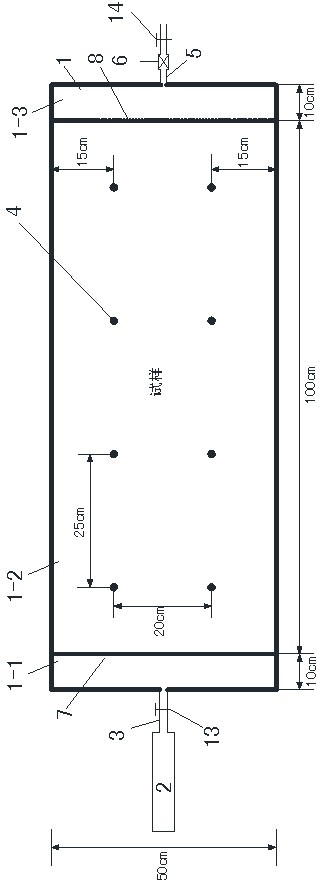

[0018] Example: such as figure 1 , 2 As shown, the piping test device of the present invention includes a sample box 1, a variable head water tank 2, an inlet pipe 3, a piezometer 4, an outlet pipe 5 and a turbidimeter 6, and the sample box 1 passes through an upstream perforated plate 7 and The downstream porous plate 8 is divided into an upstream buffer zone 1-1, a sample area 1-2 and a downstream buffer zone 1-3, and the sample is arranged in the sample area 1-2; the variable water head water tank 2 passes through the water inlet pipe 3. Connected to the upstream buffer zone 1-1 water inlet of the sample box 1; the piezometer 4 is multiple, and is set in the sample as required; the outlet pipe 5 is set in the downstream buffer zone At the water outlet of Zone 1-3, the turbidity meter 6 is arranged on the water outlet pipe 5; the upper surface of the sample is provided with a steel backing plate 9 that can slide up and down, and the upper part of the steel backing plate 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com