Large-scale piping testing apparatus capable of simulating overburden pressure of soil and testing method using large-scale piping testing apparatus

A test device and piping technology, which is used in soil material testing, material inspection products, etc., can solve the problems that the actual process of soil piping cannot be correctly reflected, the model size is small, and the development mechanism of piping cannot be fully and objectively revealed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

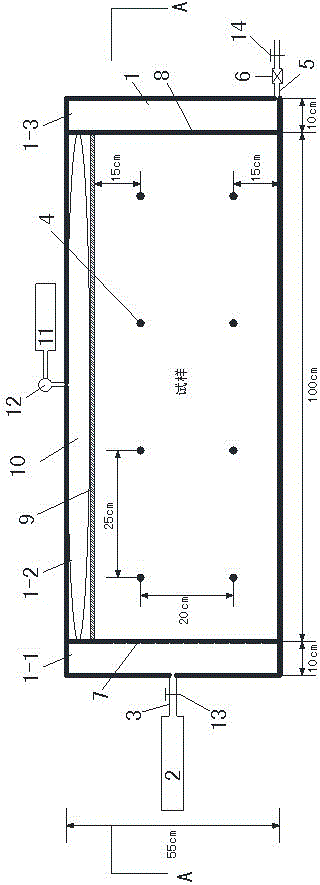

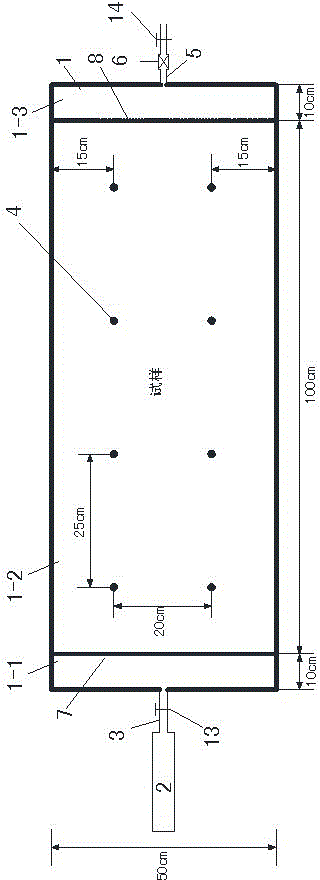

[0018] Example: Such as figure 1 , 2 As shown, the piping test device of the present invention includes a sample box 1, a variable head water tank 2, an inlet pipe 3, a piezometer 4, an outlet pipe 5 and a turbidimeter 6, and the sample box 1 passes through an upstream perforated plate 7 and The downstream porous plate 8 is divided into an upstream buffer zone 1-1, a sample area 1-2 and a downstream buffer zone 1-3, and the sample is arranged in the sample area 1-2; the variable water head water tank 2 passes through the water inlet pipe 3. Connected to the upstream buffer zone 1-1 water inlet of the sample box 1; the piezometer 4 is multiple, and is set in the sample as required; the outlet pipe 5 is set in the downstream buffer zone At the water outlet of Zone 1-3, the turbidity meter 6 is arranged on the water outlet pipe 5; the upper surface of the sample is provided with a steel backing plate 9 that can slide up and down, and the upper part of the steel backing plate 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com