Test method for cyclic fatigue life under condition of piezoelectric ceramics force electric coupling

A technology of piezoelectric ceramics and testing methods, which is applied in the direction of testing the strength of materials by applying repetitive force/pulsation force, etc., can solve the problems of difficulty in guaranteeing residual strength, exaggerated fatigue, and the stress state of ball compression method is not a standard stress state, etc. To achieve the effect of simple and feasible test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a test method for the cyclic fatigue life of piezoelectric ceramics under electromechanical coupling conditions. The samples used in this method are obtained by the following method: using PZT52 / 48 bulk piezoelectric ceramics purchased in the market, cut A square piece with a thickness of about 1mm and a side length of 10mm was produced, then after rough grinding and fine grinding, and finally a sample with a thickness of about 0.7mm was made by single-sided polishing with 1μm diamond, and silver electrodes were plated on both sides.

[0028] Using load control to test the cyclic fatigue performance of PZT ceramics, the steps are as follows:

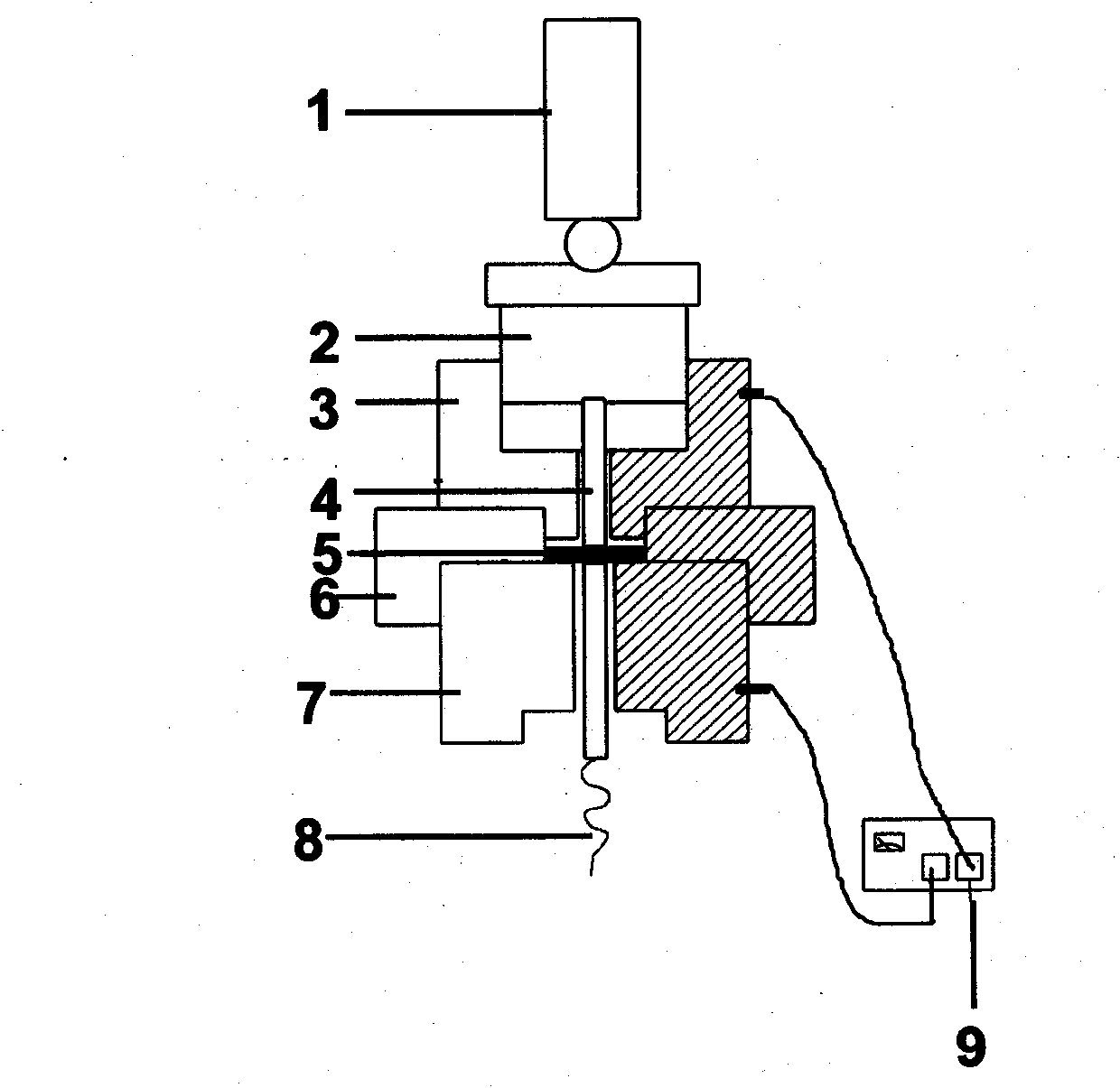

[0029] Step 1. Apply an AC electric field to the sample 5 through the lower guide mold 3 and the lower carrier mold 7 from the high-voltage power supply 9, the amplitude of the AC electric field is 600V / mm, and the frequency is 50Hz;

[0030] Step 2. Apply load-controlled cyclic fatigue loading to the sam...

Embodiment 2

[0034] This embodiment discloses a test method for the cyclic fatigue life of piezoelectric ceramics under electromechanical coupling conditions. The samples used in this method are obtained by the following method: using PZT52 / 48 bulk piezoelectric ceramics purchased in the market, cut A disc with a thickness of about 1mm and a diameter of 10mm was produced, then after rough grinding and fine grinding, and finally a sample with a thickness of about 0.5mm was made by single-side polishing with 1μm diamond, and silver electrodes were plated on both sides respectively.

[0035] Using load control to test the cyclic fatigue performance of PZT ceramics, the steps are as follows:

[0036] Step 1. Apply an AC electric field to the sample 5 through the lower guide mold 3 and the lower carrier mold 7 from the high-voltage power supply 9, the amplitude of the AC electric field is 600V / mm, and the frequency is 50Hz;

[0037] Step 2. Apply load-controlled cyclic fatigue loading to the sa...

Embodiment 3

[0041] This embodiment discloses a test method for the cyclic fatigue life of piezoelectric ceramics under electromechanical coupling conditions. The samples used in this method are obtained by the following method: using PZT52 / 48 bulk piezoelectric ceramics purchased in the market, cut A disc with a thickness of about 1mm and a diameter of 10mm is produced, then after rough grinding and fine grinding, and finally a sample with a thickness of about 0.3mm is made by single-side polishing with 1μm diamond, and silver electrodes are plated on both sides respectively.

[0042] Using load control to test the cyclic fatigue performance of PZT ceramics, the steps are as follows:

[0043] Step 1. Apply a DC electric field to the sample 5 through the lower guide mold 3 and the lower carrier mold 7 from the high-voltage power supply 9. The amplitudes of the DC electric fields are respectively -1000V / mm, and the negative electric field means that the direction of the electric field is opp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com