Device and method for detecting vibration isolation performance consistency of oversized optical platform

A technology of optical platform and detection device, which is applied in the field of optical measurement, can solve the problems of lack of laboratory and production units and complex operation of instruments, and achieve the effects of intuitive measurement results, convenient operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

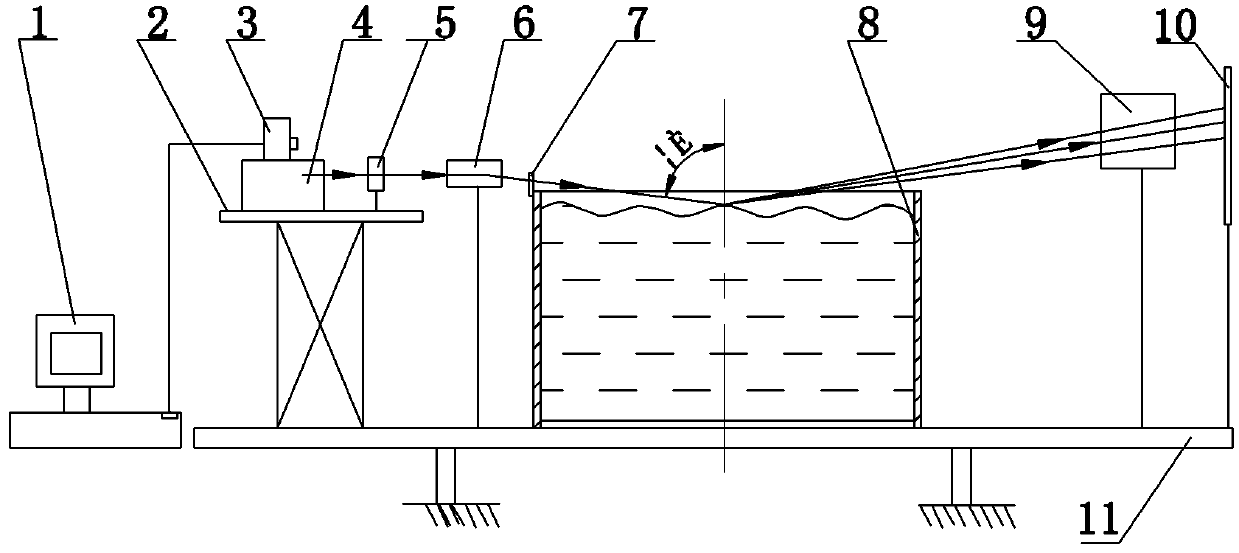

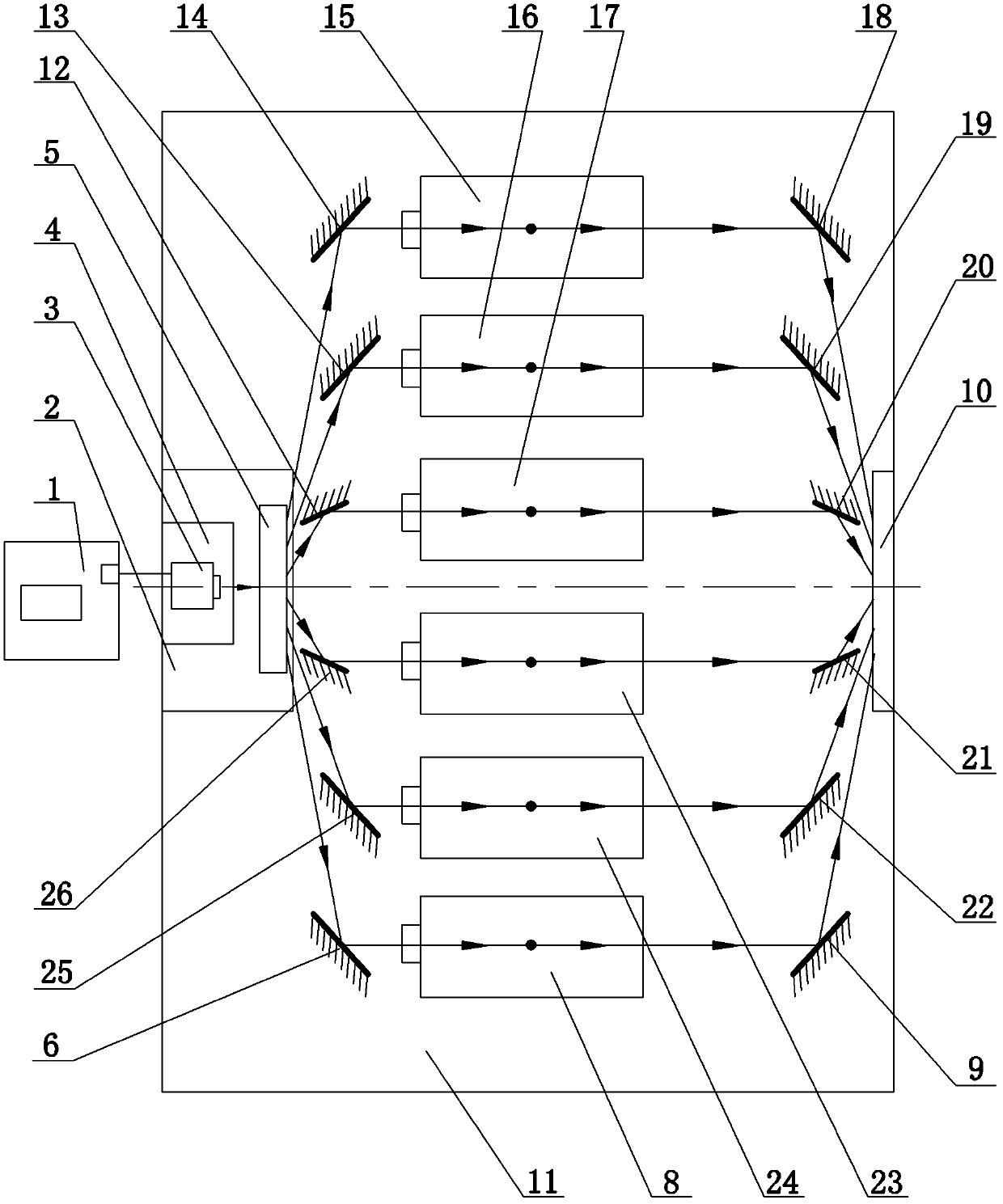

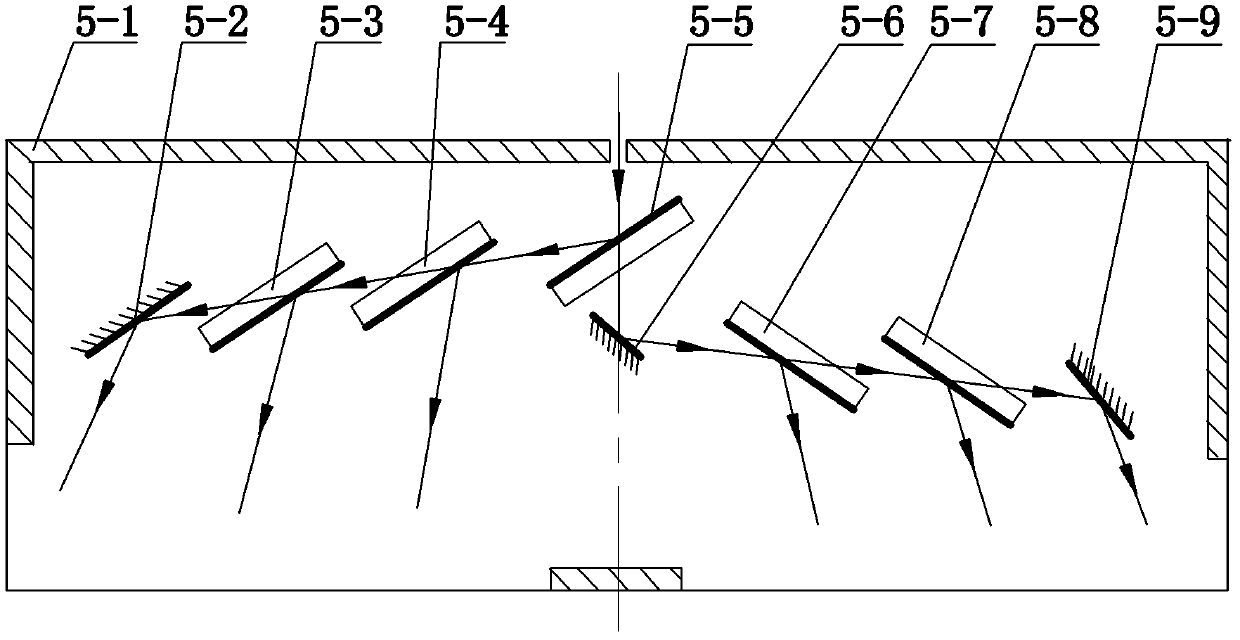

[0029] exist figure 1 , 2 , 3, the optical platform vibration characteristic acousto-optic modulation detection device of the present embodiment is made up of computer 1, support 2, CCD camera 3, laser device 4, beam splitter 5, the first left reflecting mirror 6, aperture 7, the first water tank 8. The first right reflector 9, the display screen 10, the fourth left reflector 12, the fifth left reflector 13, the sixth left reflector 14, the sixth water tank 15, the fifth water tank 16, the fourth water tank 17, the Six right reflectors 18, the fifth right reflector 19, the fourth right reflector 20, the third right reflector 21, the second right reflector 22, the third water tank 23, the second water tank 24, the second left reflector 25 , The third left reflector 26 constitutes.

[0030] A support 2 is provided at the left end of the centerline on the optical platform 11 table, and a display screen 10 is provided at the right end. The left side on the support 2 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com