A central heating system with large temperature difference using industrial waste heat

A central heating and industrial waste heat technology, applied in hot water central heating systems, heating systems, household heating, etc., can solve the problems of waste, increased investment, heavy weight, etc., and achieve convenient transportation, less investment, and increased transportation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

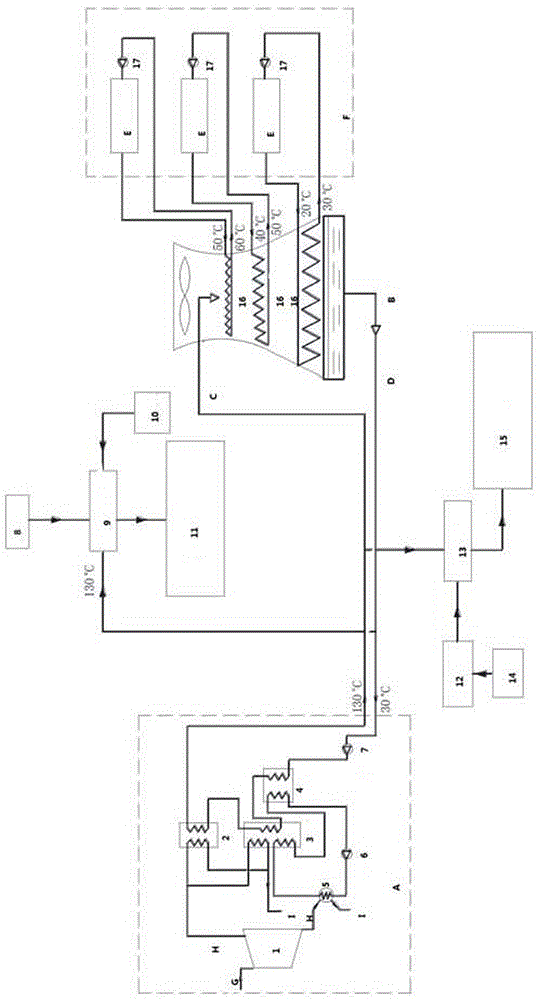

[0028] The content of the present invention will be described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0029] A central heating system with large temperature difference using industrial waste heat, such as figure 1 As shown, it includes the absorption heat pump heating system A of the power plant, the thermal cooling tower B, the end user E, and the main heating area F in the city center. An electric heat pump unit is set in the absorption heat pump heating system A of the power plant, and the electric heat pump unit is set in series with it Absorption heat pump waste heat recovery special unit.

[0030] Electric heat pump units and absorption heat pump waste heat recovery units specifically include steam turbine 1, steam-water heat exchanger 2, absorption heat pump 3, electric heat pump 4, condenser 5, cooling cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com