Fixed-point gel-placing water shutoff profile control agent and use method thereof

A technology of water profile control agent and gel, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve problems such as hindering the advancing route of the slug behind and difficult to realize deep water plugging and profile control, and shorten the construction period. Period, the effect of ensuring the effect of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

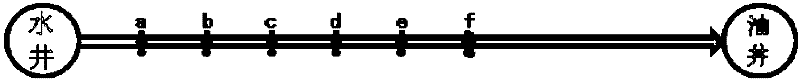

[0022] Embodiment 1: No. 1 water well and oil well, refer to figure 1 .

[0023] Step 1. On February 3 of a certain year, inject 1.5% ammonium thiocyanate and sodium bromide aqueous solution into the No. 1 water well through a cement truck. 3 . And start timing, and stop timing when the tracer is detected in the oil well on February 29, and the cumulative journey is 26 days. Take the water well as the starting point and connect a straight line with the oil well as the end point. The 70% point of the distance between the oil and water wells in the advancing direction of the injected water is the remote target position point for profile control. The distance between the remote target position point (F) and the water well is The horizontal distance between them is equally divided into six sections; the end point of each section is set as a target location point, and each target location point is sorted into target location points A, B, C, D, E, and F in turn.

[0024] Step 2. ...

Embodiment 2

[0071] Embodiment 2: No. 2 water well and oil well, refer to figure 1 .

[0072] Step 1. On March 10 of a certain year, the actual daily water injection is 23m 3 , inject 15m of 1.5% ammonium thiocyanate and sodium bromide aqueous solution into the No. 2 water well by cement truck 3 . And start timing, and stop timing on April 14 when the tracer is detected in the oil well, and the accumulated journey is 35 days. Taking the water well as the starting point and the oil well as the end point to connect a straight line, the 60% point of the distance between the oil and water wells in the advancing direction of the injected water is the remote target point of profile control, and the distance between the remote target point (F*) and the water well The horizontal distance between them is equally divided into six segments; the end point of each segment is set as a target position point, and each target position point is sorted into target position points A*, B*, C*, D*, E* , F*....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com