Weathering steel flame straightening process

A technology of flame straightening and weathering steel, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

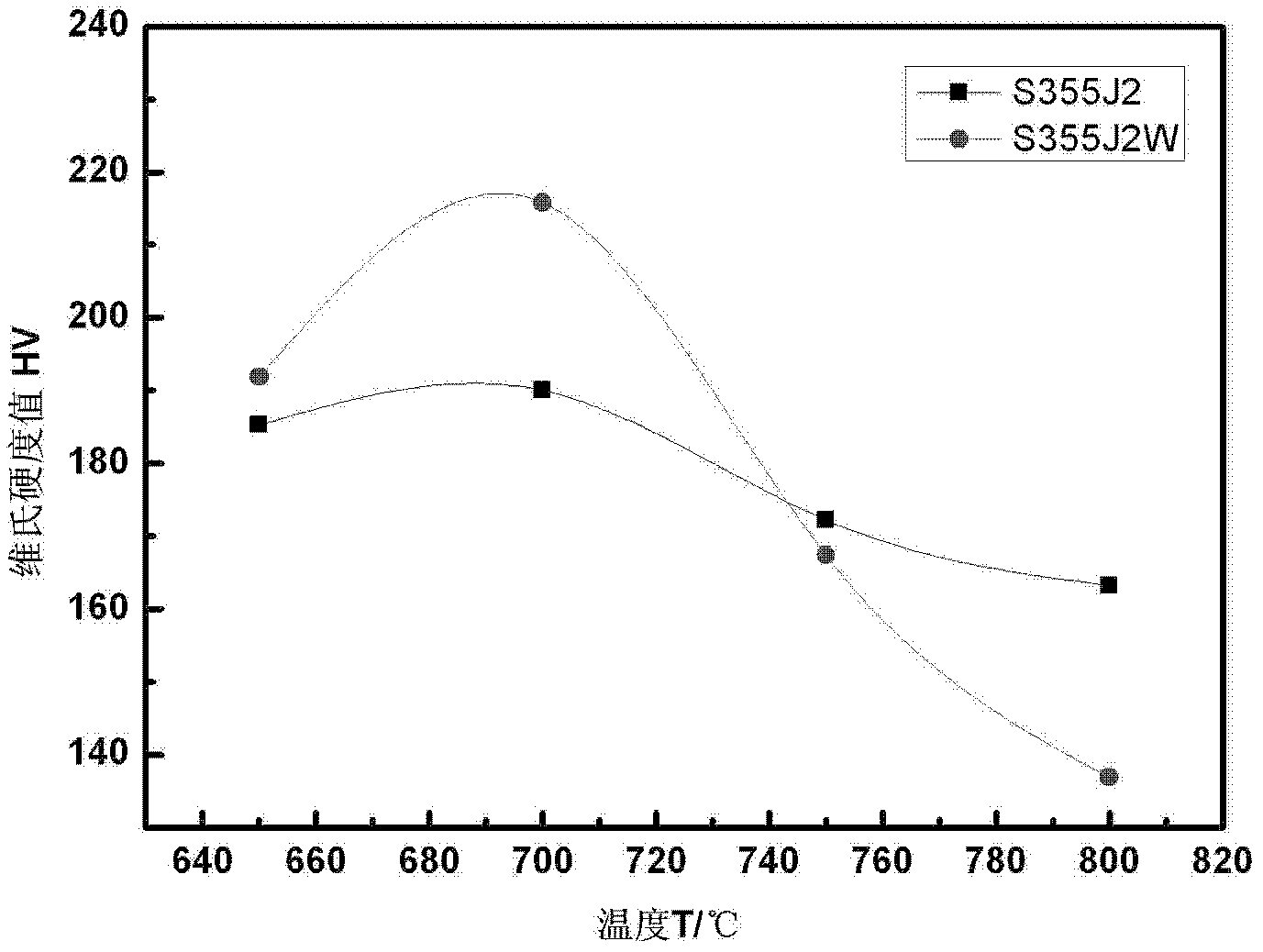

[0022] The following takes S355J2W weathering steel as an example, and describes the implementation steps and technical points of this process in conjunction with the attached drawings:

[0023] (1) Select the measurement temperature range -32°C to 1350°C, the measurement distance ratio is 30:1, the measurement accuracy is ±1.5%, the resolution is 0.1°C, the response time is <1 second, the spectral response is 8-14um, and the emissivity is 0.10-1.00. Adjust the infrared thermometer, read the instructions carefully before use, master the principle and method of use;

[0024] (2) According to the flame heating temperature parameters of S355J2W weathering steel, the emissivity of the infrared thermometer is actually calibrated in order to accurately control the heating specification, ( figure 2 is the relationship curve between the emissivity of the infrared thermometer actually calibrated and the surface temperature of the S355J2W weathering steel workpiece);

[0025] (3) Make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com