Oil-based ultrafine cement paste and production method thereof

An ultra-fine cement and mud technology, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large cement particles, inability to adapt to and cannot enter into ultra-fine cement, and achieves no volume shrinkage and remarkable dehydration effect. , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

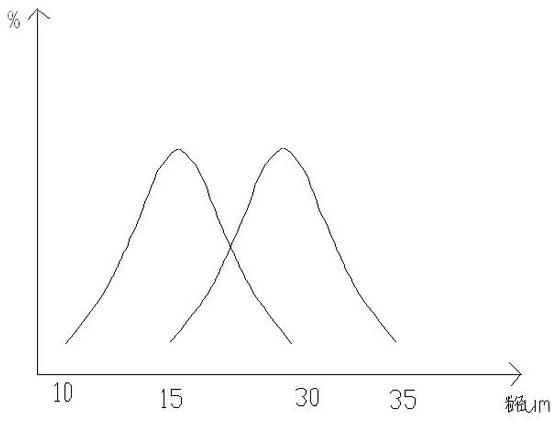

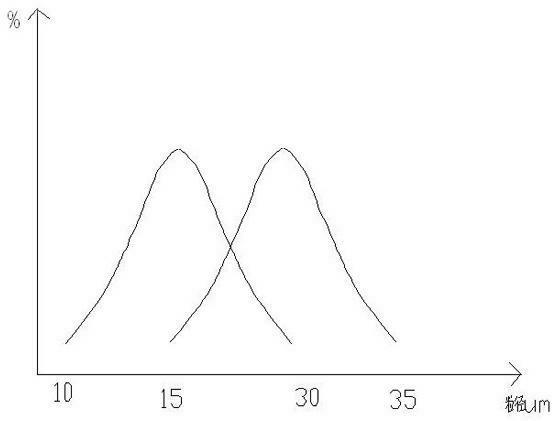

[0034] Weigh 0.8 tons of ultrafine cement with a particle size distribution of 10-15um, 0.7 tons of ultrafine cement with a particle size distribution of 30-35um, 1 cubic meter of diesel oil, and 3 kg of oil-soluble surfactant sorbitan monooleate ,stand-by;

[0035] Add diesel oil and sorbitan monooleate into the container in turn, and mix them evenly;

[0036] Adding the superfine cement into the uniformly mixed diesel oil and sorbitan monooleate, fully stirring to completely disperse the superfine cement to obtain mixed mud.

Embodiment 2

[0038] Weigh 1.5 tons of ultra-fine cement with a particle size distribution of 10-15um, 1.5 tons of ultra-fine cement with a particle size distribution of 30-35um, 1 cubic meter of diesel oil, and 10 kg of oil-soluble surfactant polyoxyethylene sorbitan Monolaurate, set aside;

[0039] Add diesel oil and polyoxyethylene sorbitan monolaurate into the container in turn to make them mix evenly;

[0040] Adding the ultrafine cement into the uniformly mixed diesel oil and polyoxyethylene sorbitan monolaurate, stirring fully to completely disperse the ultrafine cement to obtain mixed mud.

Embodiment 3

[0042] Weigh 1.4 tons of ultra-fine cement with a particle size distribution of 10-15 um, 0.6 tons of ultra-fine cement with a particle size distribution of 30-35 um, 1 cubic meter of diesel oil, and 5 kg of oil-soluble surfactant polyoxyethylene sorrel Alcohol monolaurate, set aside;

[0043]Add diesel oil and polyoxyethylene sorbitan monolaurate into the container in turn to make them mix evenly;

[0044] Adding the superfine cement into the homogeneously mixed diesel oil and polyoxyethylene sorbitan monolaurate, fully stirring to completely disperse the superfine cement to obtain mixed mud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com