Application of bimetallic cationic complex

A cationic, bimetallic technology, applied in the direction of organic chemistry, can solve the problems of unreported and cumbersome application of complexes, and achieve the effects of saving manpower and material resources, simple processing methods, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

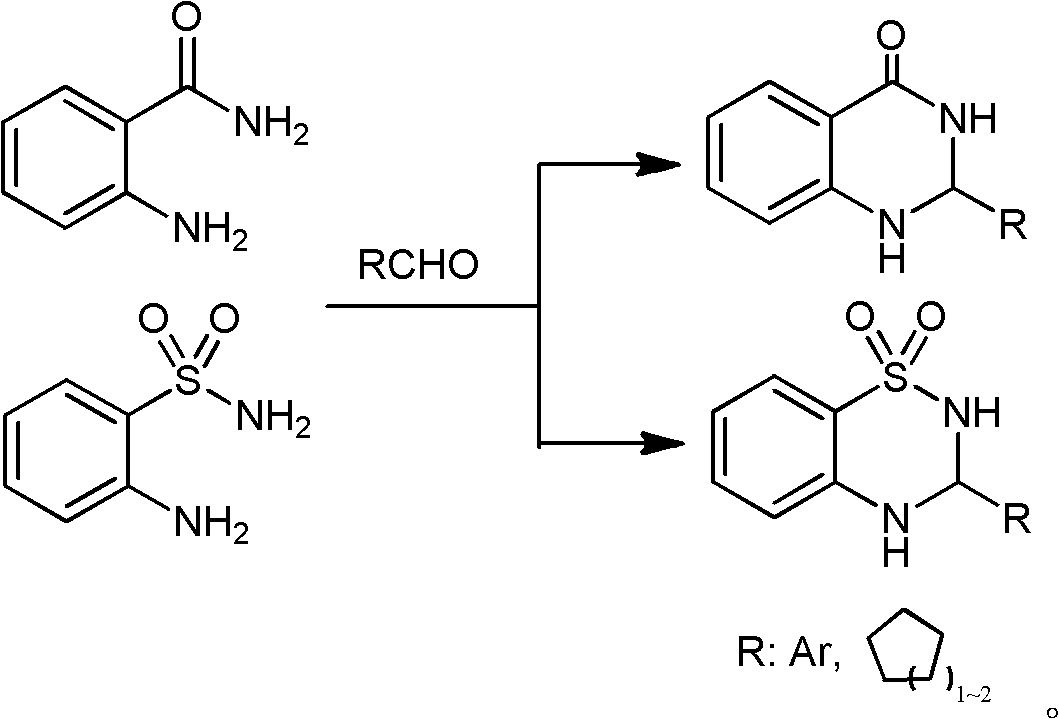

Image

Examples

Embodiment 1

[0035] Embodiment one: catalyst [La(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3- ·CH 3 Synthesis of CN

[0036] In the reaction bottle that has been dehydrated and deoxygenated, under the protection of argon, weigh LaCl at a molar ratio of 1:3. 3 and anhydrous AlCl 3 , add an appropriate amount of acetonitrile to dissolve, stir at room temperature for 24 hours, centrifuge, take the supernatant, concentrate and put it in a refrigerator at 0°C, the obtained crystal is [La(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3- ·CH 3 CN, 40% yield.

[0037] The product is white, elemental analysis: La, (13.16±0.5)%, Cl, (40.29±0.5)%.

Embodiment 2

[0038] Embodiment two: catalyst [Pr(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3- ·CH 3 Synthesis of CN

[0039] In the reaction flask that has been dehydrated and deoxygenated, weigh PrCl at a molar ratio of 1:3 under the protection of argon. 3 and anhydrous AlCl 3 , add an appropriate amount of acetonitrile to dissolve, stir at room temperature for 24 hours, centrifuge, take the supernatant, concentrate and put it in a refrigerator at 0°C, the obtained crystal is [Pr(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3- ·CH 3 CN, yield 46%.

[0040] The product is light green, elemental analysis: Pr, (13.32±0.5)%, Cl, (40.20±0.5)%.

Embodiment 3

[0041] Embodiment three: catalyst [Nd(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3- ·CH 3 Synthesis of CN

[0042] In the reaction flask that has been dehydrated and deoxygenated, weigh NdCl at a molar ratio of 1:3 under the protection of argon. 3 and anhydrous AlCl 3 , add an appropriate amount of acetonitrile to dissolve, stir at room temperature for 24 hours, centrifuge, take the supernatant, concentrate and put it in a refrigerator at 0°C, the obtained crystal is [Nd(CH 3 EN) 9 ] 3+ [(AlCl 4 ) 3 ] 3- ·CH 3 CN, yield 45%.

[0043] The product is lavender, elemental analysis: Nd, (13.59±0.5)%, Cl, (40.09±0.5)%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com