High-efficient fermentation method of organic fertilizer and device thereof

The technology of a fermentation device and a fermentation method is applied in the field of efficient fermentation methods and devices for organic fertilizers, which can solve the problems of poor treatment site environment, slow fermentation speed, and huge loss of fertilizer nutrients, and achieve less foul odor, fast processing speed, and Good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

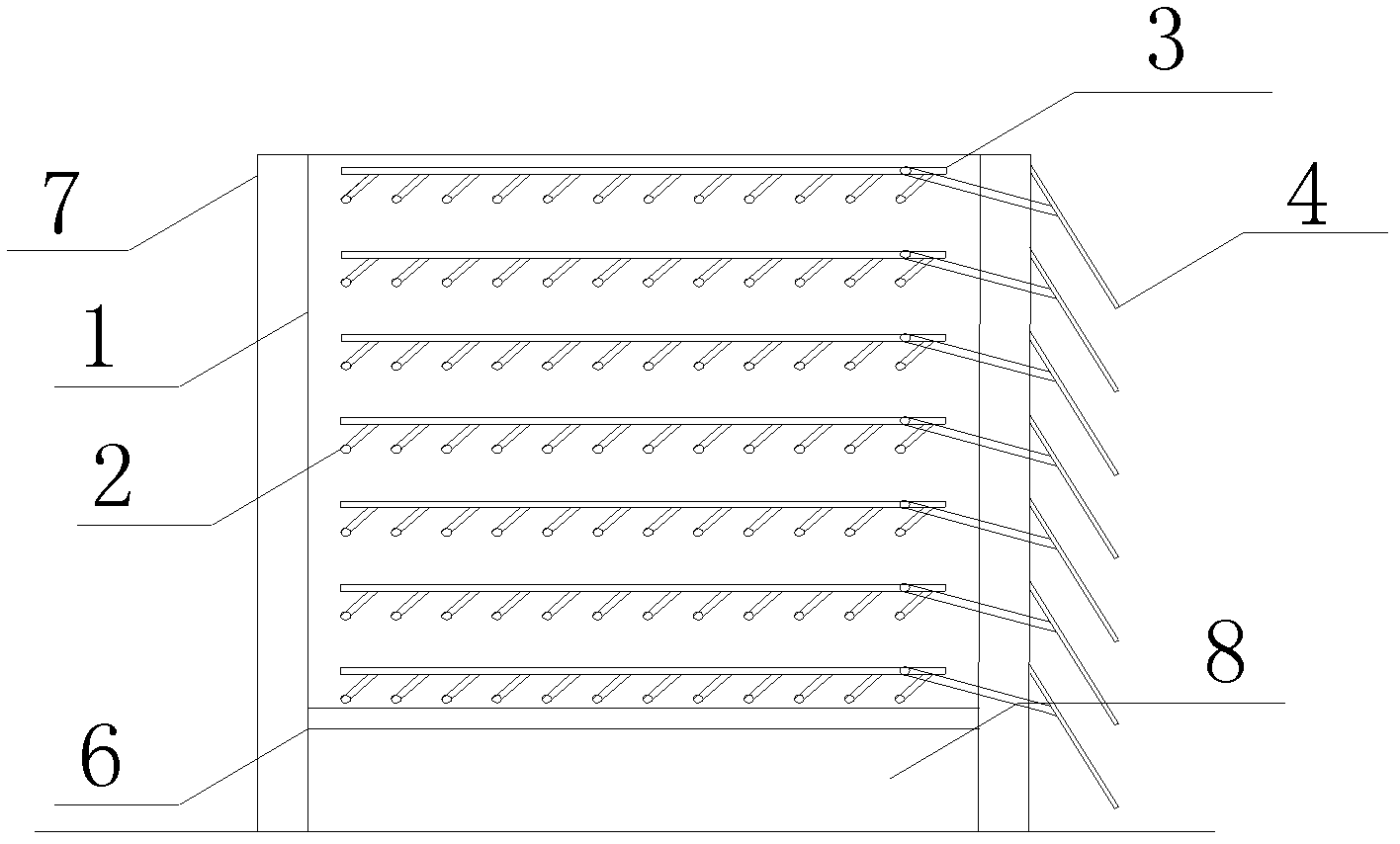

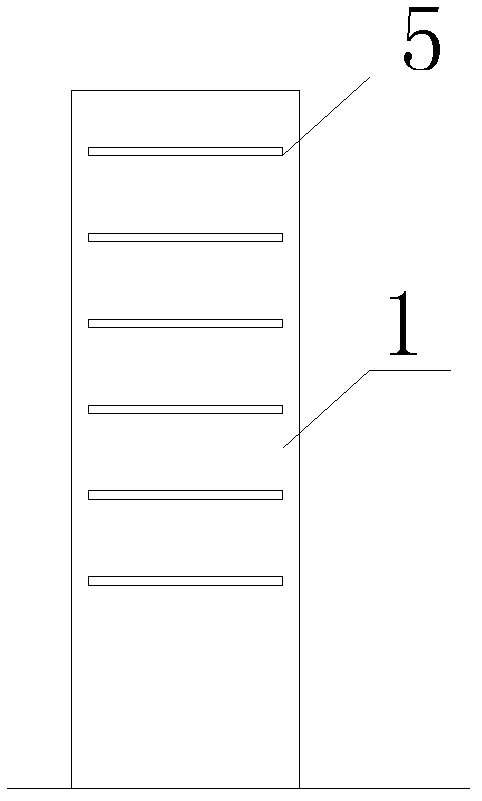

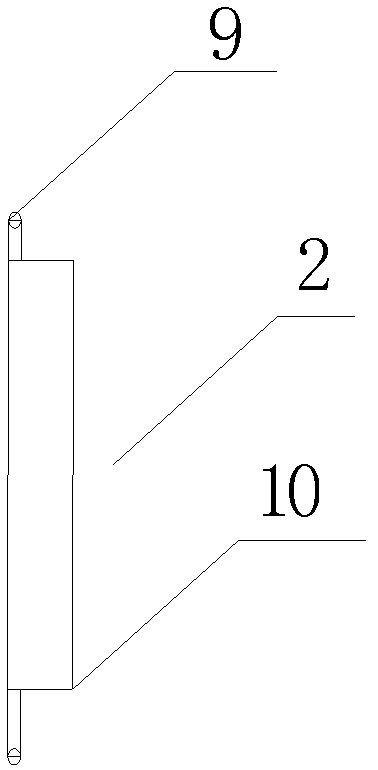

[0034]Choose a high and low sill with a height difference of about 3m, and build a fermenter 1 with an inner cross-section length and width of 2×1.5m, which is divided into four layers, each layer is 60cm high, and the height of the lower outlet 8 of the fermenter is about 70cm. Rotary louvers 2 The leaf surface 10 has a width of 30cm and a length of about 1.45m. Each layer of the compartment is composed of 6 rotating louvers 2 arranged equidistantly. The rotating louvers 2 of each layer are all connected to the control switch 4 of the corresponding layer through the connection arm 3 On the top, the opening and closing of the compartment rotary louvers is controlled by the control switch 4. On the fermenter tank body 1, a ventilation hole 5 with a height of about 4 to 6 cm is set on the side wall at a distance of about 3 to 5 cm from the upper layer of the interlayer on each layer, and a vent hole 5 with a height of about 20 cm is built outside the side wall to be connected to ...

Embodiment 2

[0038] Choose a high and low sill with a height difference of about 4m, and build a fermenter 1 with an inner cross-section length and width of 2m×4m, which is divided into six layers, each layer is 60cm high, and the height of the lower discharge port 8 of the fermenter is about 70cm, with 2 rotating louvers The surface 10 has a width of 30cm and a length of about 1.95m. Each interlayer is composed of 13 rotating louvers 2 arranged equidistantly. The rotating louvers 2 of each layer are all connected to the control switch 4 of the corresponding layer through the connecting arm 3 , the opening and closing of the compartment rotary louvers is controlled by the control switch 4. On the fermenter tank body 1, a ventilation hole 5 with a height of about 4 to 6 cm is set on the side wall at a distance of about 3 to 5 cm from the upper layer of the interlayer on each layer, and a vent hole 5 with a height of about 20 cm is built outside the side wall to be connected to the side wall,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com