Urea melting equipment and application method thereof

A melting equipment, urea technology, applied in application, urea compound fertilizer, nitrogen fertilizer and other directions, can solve the problems affecting heat transfer efficiency, steam coil wall thickness, etc., and achieve the effect of increasing the heating area, reducing energy consumption, and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

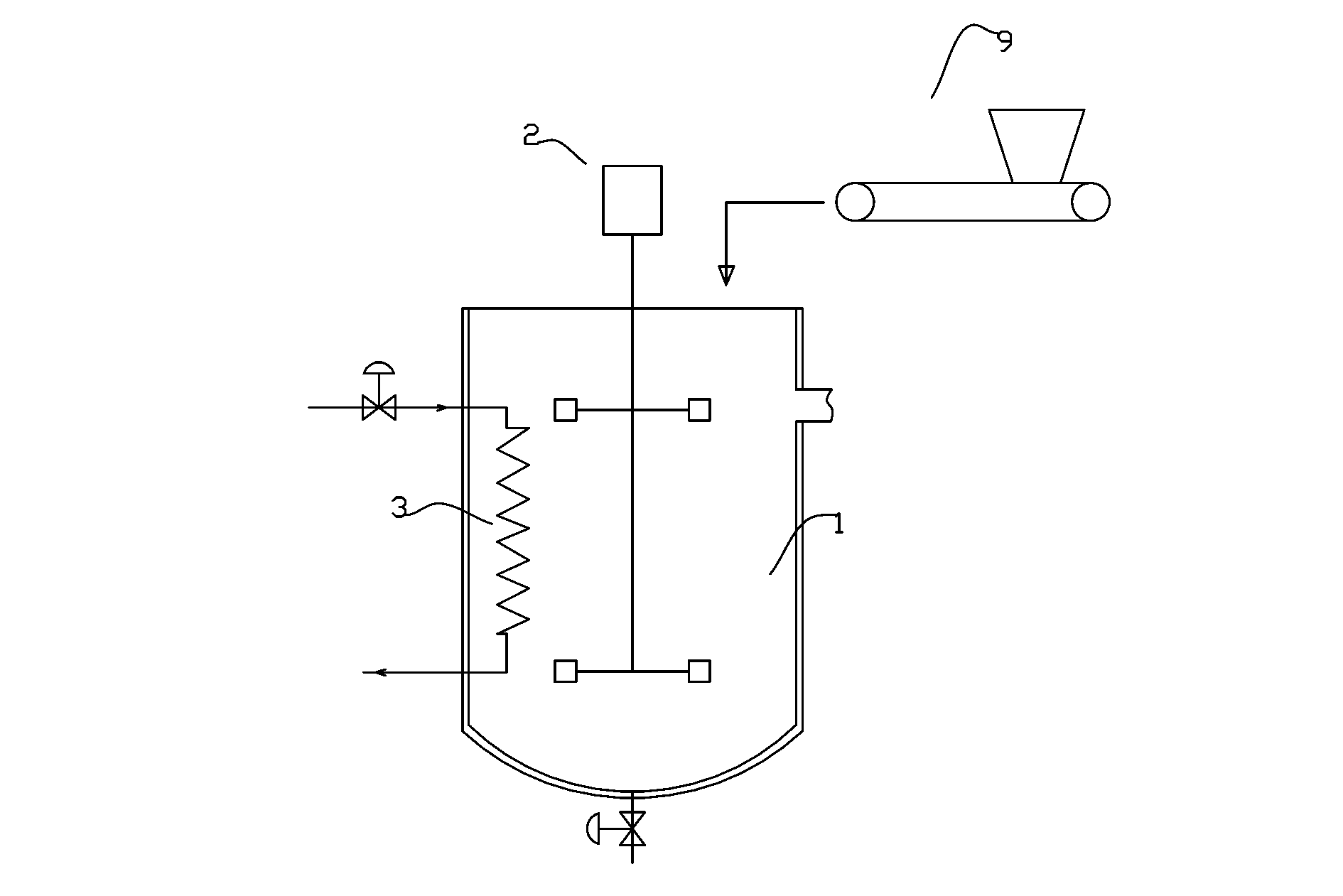

[0023] Such as figure 2 As shown, the present invention is a urea melting equipment, including a melting tank 1 , a stirring device 2 , a heating coil 3 , a hot oil tank 6 , and a heating conduit 5 . The stirring device 2 is a stirring motor 21 , a stirring shaft 22 driven by the stirring motor 21 and a turning leaf 23 on the stirring shaft 22 ; a crawler feeder 9 is arranged above the melting tank 1 . The heating coil 3 is arranged in the melting tank 1 , and the heating plate 3 is externally connected to the thermal oil tank 6 through the heating conduit 5 , and the thermal oil tank 6 and the heating coil 5 form a thermal oil circulation loop through the heating conduit 5 . The heating conduit 5 on the hot oil circulation circuit is specifically divided into an upper heating conduit 51 and a lower heating conduit 52, which respectively form an upper heating oil circulation channel and a lower heating oil circulation channel, and on the lower heating conduit 52, a thermal oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com