Hydraulic rotary system and engineering vehicle

A rotary system, hydraulic technology, applied in the direction of fluid pressure actuating devices, servo motors, servo motor components, etc., can solve problems such as pressure fluctuations in the hydraulic system, eliminate pressure fluctuations, improve stability and comfort, and simple control schemes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

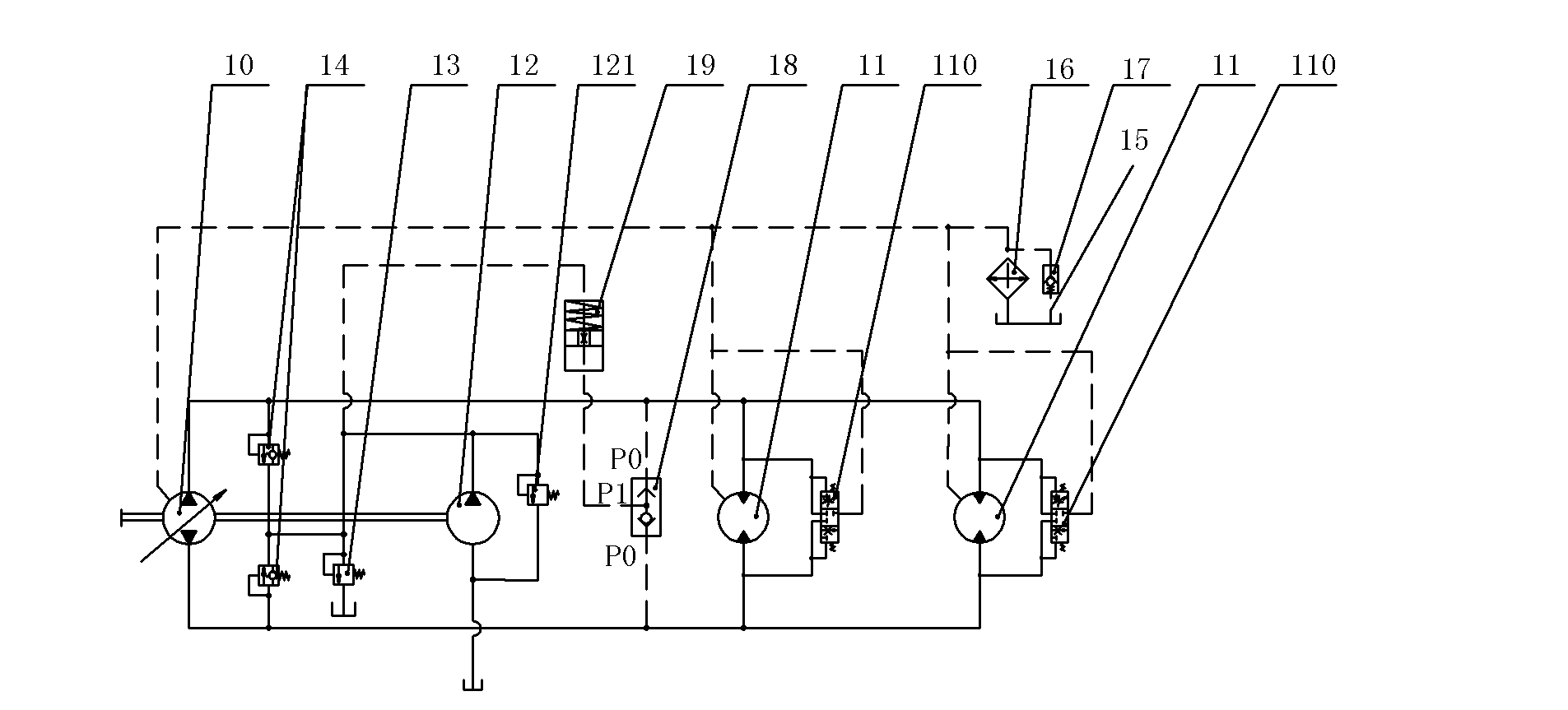

[0024] Please refer to figure 1 , which shows a hydraulic schematic diagram of an embodiment of the hydraulic swing system according to the present invention. The hydraulic slewing system includes: a slewing variable pump 10, a supplementary oil circuit connected in parallel to both ends of the slewing variable pump 10, a slewing motor 11 directly connected to the slewing variable pump 10, and a slewing buffer device. The number of slewing motors 11 is one or more. A flushing valve 110 is connected in parallel at both ends of the swing motor 11 , and the swing buffer device is connected in parallel at both ends of the swing motor 11 and communicated with the oil supply circuit for buffering pressure fluctuations in the hydraulic swing system. Wherein, the charging circuit includes a charging pump 12 and a charging pressure relief valve 13 , the charging pump 12 is coaxially driven with the rotary variable displacement pump 10 , and a charging safety overflow valve 121 is conne...

Embodiment 2

[0035] see Figure 4 , which shows a schematic diagram of the hydraulic principle of the second embodiment of the hydraulic swing system according to the present invention. The hydraulic slewing system includes: a slewing variable pump 20, an oil supply circuit connected in parallel at both ends of the slewing variable pump 20, a slewing motor 21 directly connected to the slewing variable pump 20, and a slewing buffer device. The number of slewing motors 21 is one or more. A flushing valve 210 is connected in parallel at both ends of the swing motor 21 , and the swing buffer device is connected in parallel at both ends of the swing motor 21 and communicated with the oil supply circuit for buffering pressure fluctuations in the hydraulic swing system. Wherein, the charging circuit includes a charging pump 22 and a charging pressure relief valve 23 , the charging pump 22 is coaxially driven with the rotary variable displacement pump 20 , and a charging safety overflow valve 221 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com