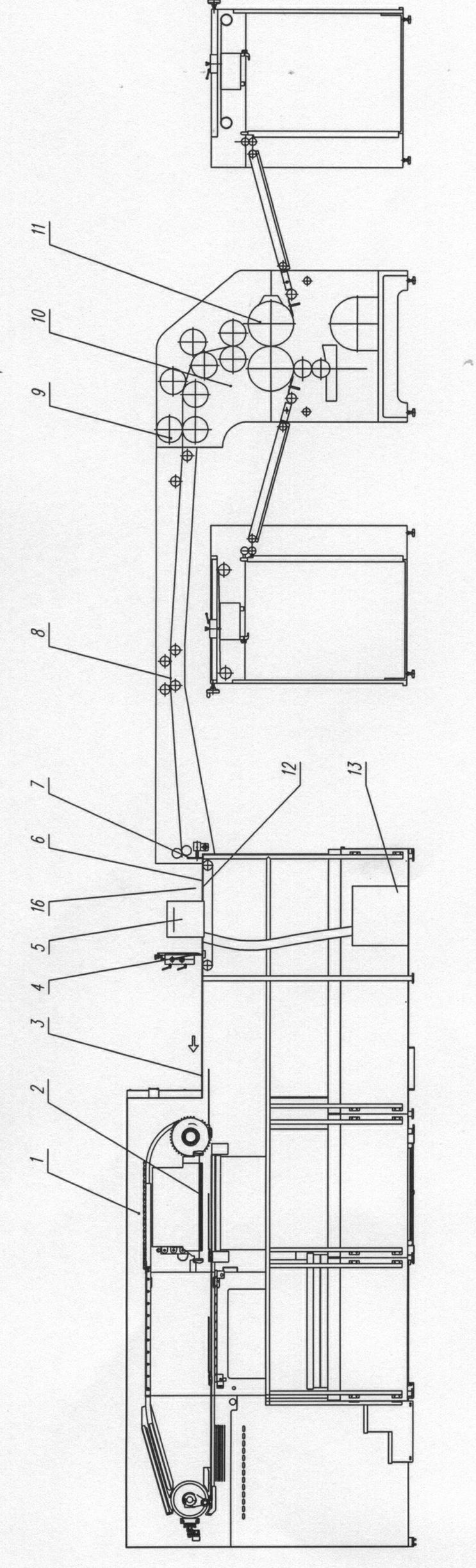

Laminating and die cutting integrated paperboard forming machine

A technology that integrates mounting cards and forming machines, applied in machining/deformation, metal processing, etc., can solve the problems of low production efficiency and high production cost, achieve synchronous die-cutting, speed up composite speed, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Referring to the accompanying drawings, this kind of cardboard forming machine integrating cardboard mounting and die-cutting includes a cardboard mounting unit 10 and a die-cutting unit 1. The cardboard mounting unit 10 includes a composite roller 11, a conveying roller 9 and a motor. Described composite roll 11 is connected with motor, and described die-cutting unit 1 comprises die-cutting knife 2 and motor, and described die-cutting knife 2 is connected with motor, and the front of described die-cutting unit 1 is provided with connecting platform 6, and described A conveyer belt 8 is arranged between the connecting platform 6 and the conveying roller 9 of the mounting card unit 1, and the conveying belt 8 is arranged on a transmission wheel, and the transmission wheel is connected with a motor. Paper machine, described air suction paper feeder includes paper storehouse 16 and air suction belt 12, is provided with air suction hole on described air suction belt 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com