Dynamical system for loadage of grinding body in cylinder type ball mill and application method of dynamical system

A dynamic system and application method technology, applied in grain processing and other directions, can solve problems such as affecting production efficiency and product quality, mechanical damage to the main shaft of the ball mill, and consumption of the ball mill lining plate of the grinding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Furnace 2# of a power plant is equipped with 2 cylindrical ball mills, the model is DTM320 / 580 steel ball coal mill, the grinding body is steel ball, the rated loading capacity of steel ball is 50t, and the rated current is 88A. The no-load current of the coal mill before transformation is 55-58A, and the operating current is 63-66A. The method of adding steel balls is to estimate the addition method based on the no-load current every week. Select 70% of the rated initial load of balls, and start with 35t, for dynamic optimization of the grinding body.

[0114] according to figure 1 As shown, add material level measuring point, ball adding machine and pulverizing optimization control system.

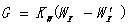

[0115] according to figure 2 As shown, select the maximum output as the target parameter, optimize the milling system, and select the steel ball increment δ Q Take 0.5t; the rated output of the ball mill is 60t / h, θ Y Take the rated value of 0.3t / h; to obtain the current I i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com