SiC-graphene nano-composite and preparation method thereof

A nano-composite material and graphene technology, applied in the field of SiC-graphene nano-composite materials and its preparation, can solve problems such as complex processes, achieve the effects of simple process steps, low production costs, and stable physical and chemical structures and properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

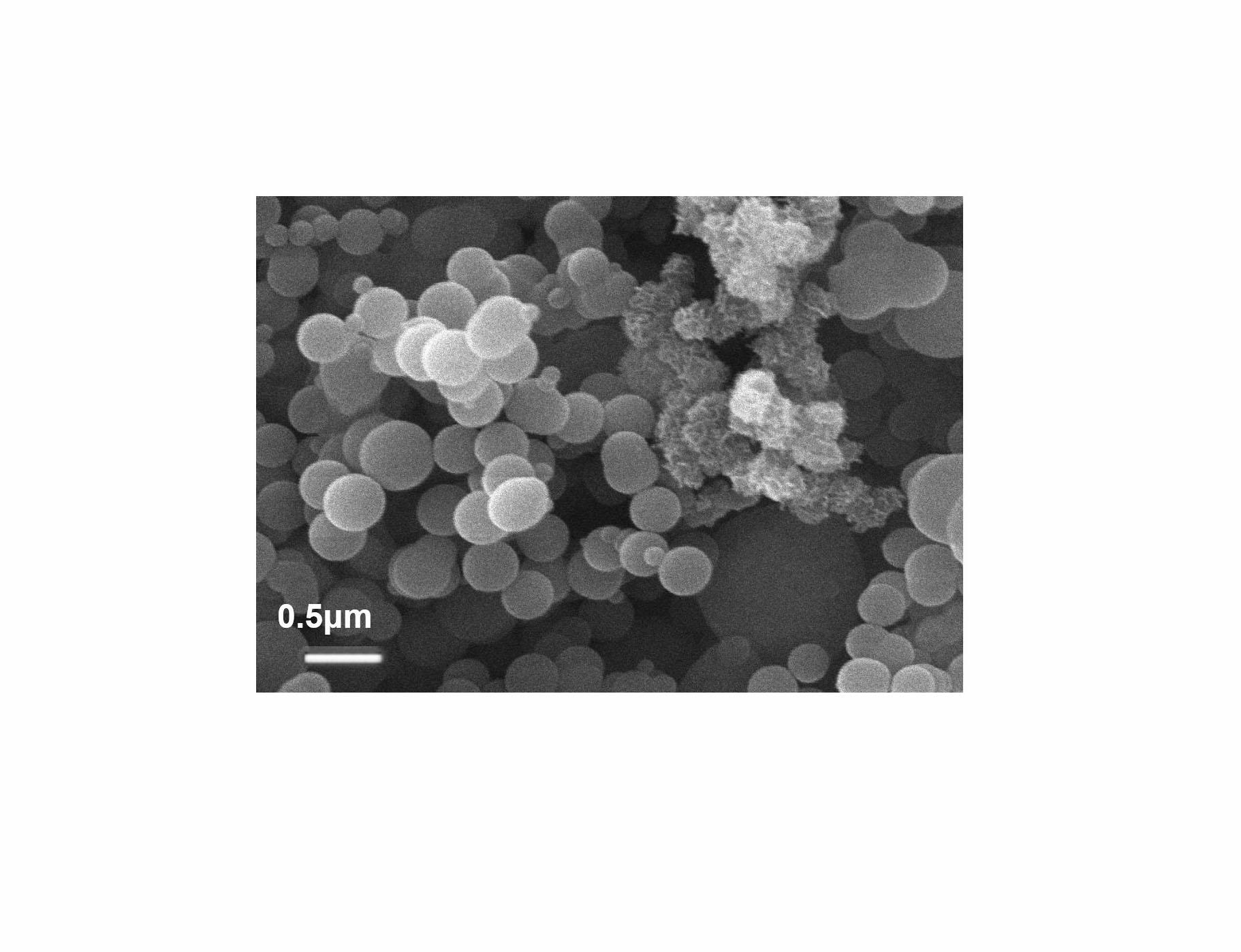

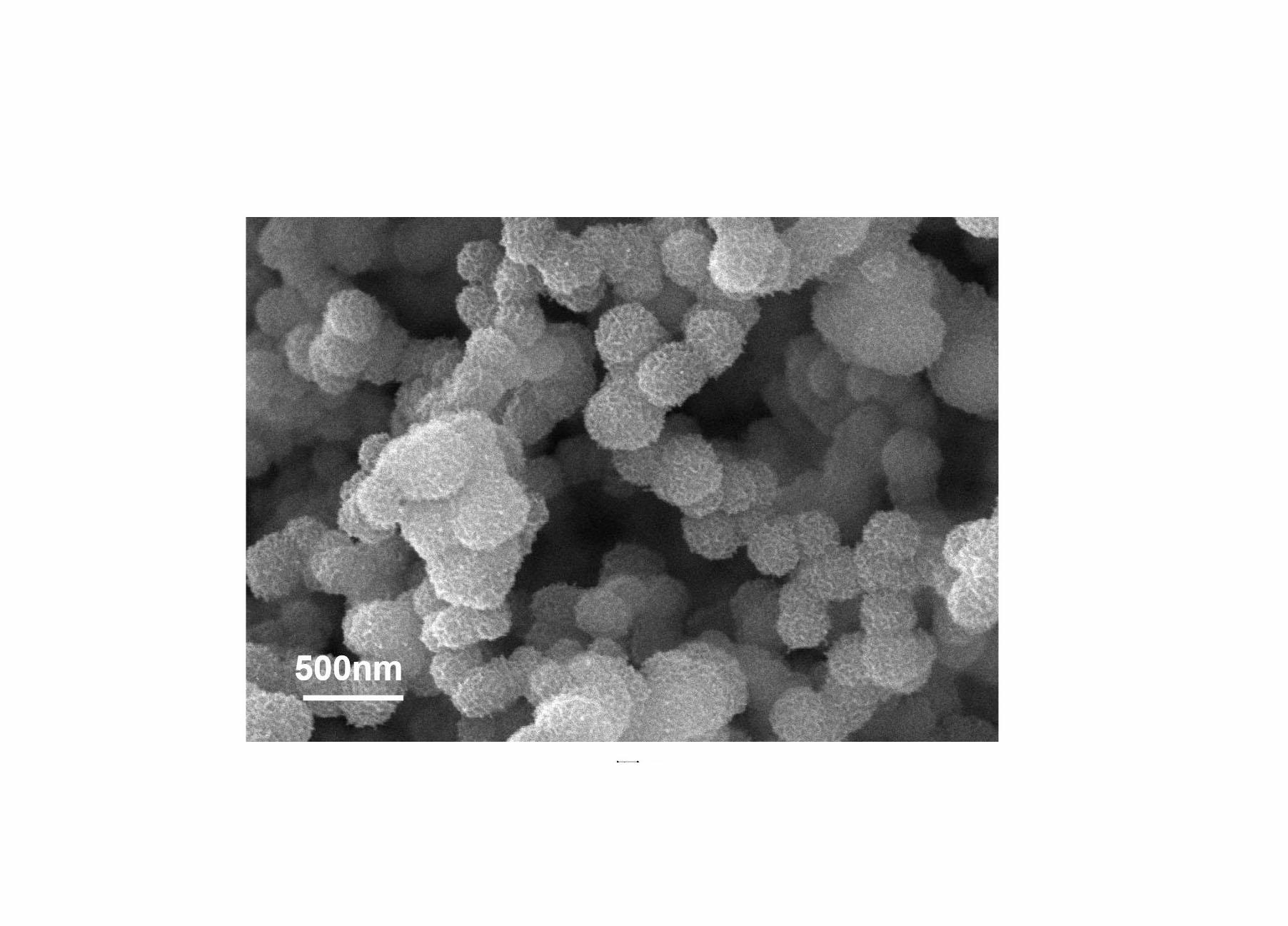

[0027] A SiC-graphene nanocomposite material of the present invention is a core-shell structure in which an outer shell covers a core, the inner core is SiC nanoparticles, and the outer shell is nano-graphite composed of graphene. SiC-graphene nanocomposites are generally spherical particles with a diameter of 100 nm to 300 nm and a feather-like surface. Graphene in nano-graphite has 8-15 layers and grows along the radial direction of SiC nanoparticles.

[0028] The above-mentioned SiC-graphene nanocomposite material is prepared through the following steps:

[0029] (1) Preparation:

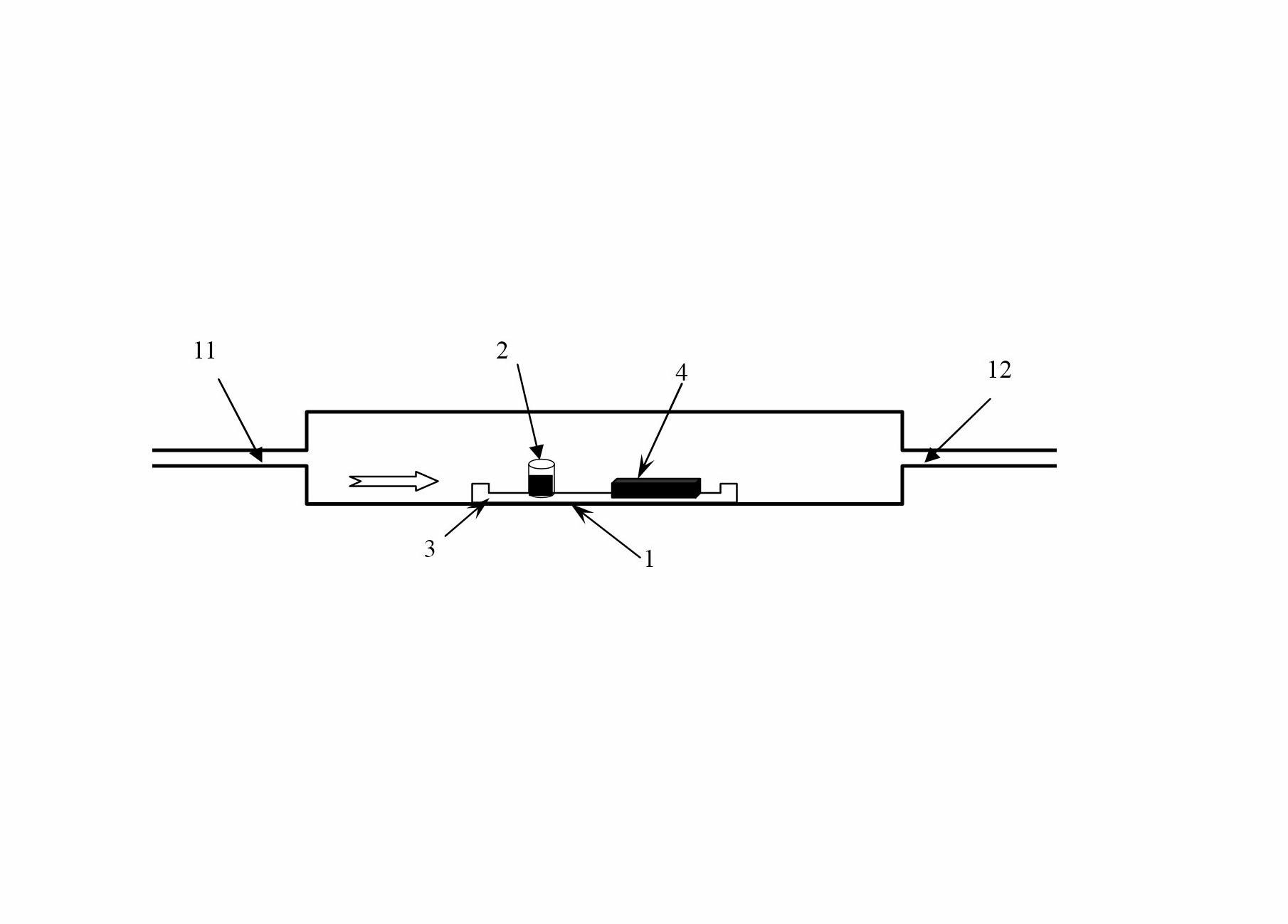

[0030] a. Prepare the process unit: if figure 1 As shown, prepare a tubular chemical vapor deposition furnace 1 with an air inlet 11 and an air outlet 12 at both ends, place a graphite boat 3 in the tubular chemical vapor deposition furnace 1, and place graphite boats 3 sequentially along the airflow direction An alumina crucible 2 for accommodating raw materials and a graphite substrate 4 for...

Embodiment 2

[0040] A SiC-graphene nanocomposite material of the present invention is a core-shell structure in which an outer shell covers a core, the inner core is SiC nanoparticles, and the outer shell is nano-graphite composed of graphene. SiC-graphene nanocomposites are generally spherical particles with a diameter of 100 nm to 200 nm and a feather-like surface. Graphene in nano-graphite has 8-15 layers and grows along the radial direction of SiC nanoparticles.

[0041] The SiC-graphene nanocomposite material of the present embodiment is prepared through the following steps:

[0042] (1) Preparation: Same as Example 1.

[0043] (2) Precursor cracking:

[0044] c. Introduce high-purity nitrogen gas into the tubular chemical vapor deposition furnace 1, and repeat 2 to 3 times to exhaust the air in the furnace.

[0045] d. Heat the tubular chemical vapor deposition furnace 1 to 800°C at a temperature increase rate of 8°C / s, keep the nitrogen flow at 30 sccm to 50 sccm during the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com