Preparation method of mulberry silk tissue engineering scaffold

A technology of tissue engineering scaffold and mulberry silk, which is applied in medical science, prosthesis, etc., can solve the problems of low porosity of scaffold model and inability to make models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

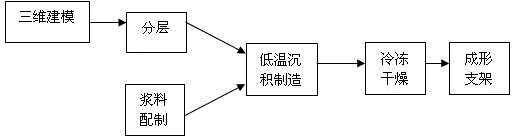

[0023] 1) Directly design with the help of 3D CAD software or use solid reverse engineering to collect the geometric shape and structural information of the prototype to obtain a 3D model.

[0024] 2) According to the above-mentioned three-dimensional model and the specific needs of the bracket, perform layering to obtain the data file formed by the low-temperature forming machine. In the layering, set the layer thickness to 0.19mm, the distance between wires to 1.3mm, and the scanning angle to 0° / 90°.

[0025] 3) slurry preparation, specifically comprising the following steps:

[0026] 3-1) Silk degumming: use 50 times the volume mass fraction of 0.5% Na 2 CO 3 solution, refine the silk twice at a temperature of 95-100° C., each time for 30-40 minutes, and rinse with deionized water for 2-3 times.

[0027] 3-2) Silk dissolution: Dissolve 10g of degummed silk in boiling 100mL CaCl with a mass fraction of 40% 2 solution, the dissolving time is 60-80 minutes, and the silk fib...

example 2

[0034] 1) Directly design with the help of 3D CAD software or use solid reverse engineering to collect the geometric shape and structural information of the prototype to obtain a 3D model.

[0035] 2) According to the above-mentioned three-dimensional model and the specific needs of the bracket, layering is carried out to obtain the data file formed by the low-temperature forming machine. In the layering, the layering thickness is set to 0.17mm, the distance between wires is 1.2mm, and the scanning angle is 0° / 90°.

[0036] 3) slurry preparation, specifically comprising the following steps:

[0037] 3-1) Silk degumming: use 50 times the volume mass fraction of 0.5% Na 2 CO 3 solution, refine the silk twice at a temperature of 95-100° C., each time for 30-40 minutes, and rinse with deionized water for 2-3 times.

[0038] 3-2) Silk dissolution: Dissolve 10g of degummed silk in boiling 100mL CaCl with a mass fraction of 40% 2 solution, the dissolving time is 60-80 minutes, and...

example 3

[0045] 1) Directly design with the help of 3D CAD software or use solid reverse engineering to collect the geometric shape and structural information of the prototype to obtain a 3D model.

[0046] 2) According to the above-mentioned three-dimensional model and the specific needs of the bracket, layering is carried out to obtain the data file formed by the low-temperature forming machine. In the layering, the layering thickness is set to 0.15mm, the distance between wires is 1.2mm, and the scanning angle is 0° / 90°.

[0047] 3) slurry preparation, specifically comprising the following steps:

[0048] 3-1) Silk degumming: use 50 times the volume mass fraction of 0.5% Na 2 CO 3 solution, refine the silk twice at a temperature of 95-100° C., each time for 30-40 minutes, and rinse with deionized water for 2-3 times.

[0049] 3-2) Silk dissolution: Dissolve 10g of degummed silk in boiling 100mL CaCl with a mass fraction of 40% 2 solution, the dissolving time is 60-80 minutes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com