Near infrared cut-off filters

A technology of cut-off filtering and near-infrared light, applied in optics, optical components, instruments, etc., can solve the problems of difficult to achieve thinning, limit the miniaturization of the camera body, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

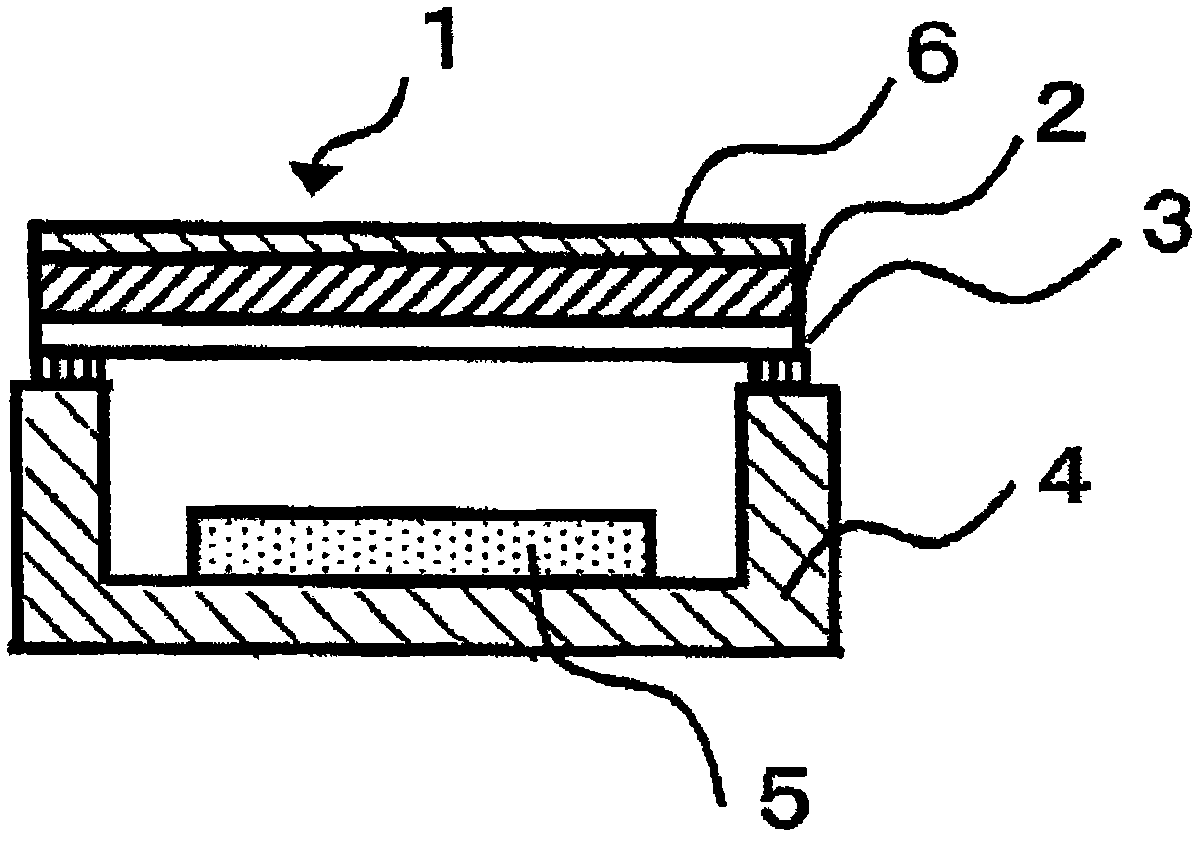

[0033] Next, embodiments of the near-infrared cut filter of the present invention will be described. figure 1 and figure 2 It is a cross-sectional view of each embodiment in which the near-infrared cut filter 1 of the present invention is mounted on a solid-state imaging device package 4 .

[0034] The near-infrared cut filter 1 has a rectangular plate-like appearance, and consists of a substrate glass 2 that can transmit visible light and cut off near-infrared rays, and a film-shaped attenuation layer 3 that is provided on the light-transmitting surface of the substrate glass 2 that faces the solid-state imaging device 5 . constitute. The substrate glass 2 emits α-rays due to the inclusion of radioactive isotopes as impurities in the glass composition, but the α-rays are attenuated by the thin-film attenuation layer 3 formed on the substrate glass 2 . Thus, even if the near-infrared cut filter 1 using the substrate glass 2 that emits α-rays is mounted on the solid-state im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com