Bonding compositions

A technology of polymers and compounds, applied in the direction of bonding method of adhesive heating, bonding method of fabric, surface pretreatment, etc., can solve problems such as performance degradation, reinforcement fiber abrasion, reinforcement fiber and rubber matrix peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

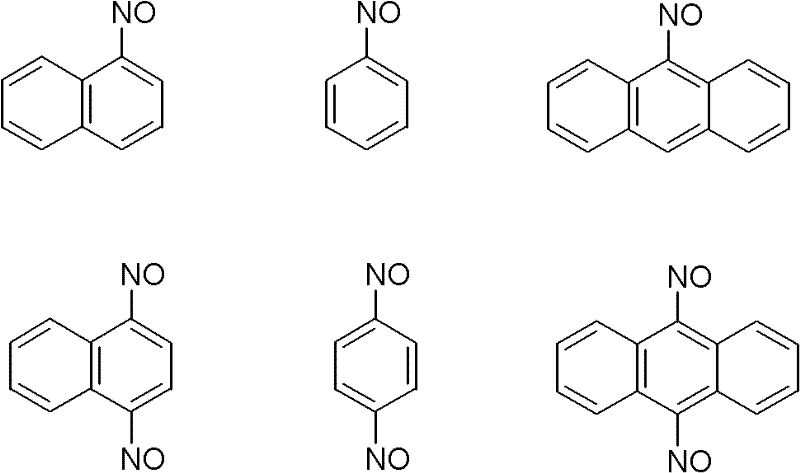

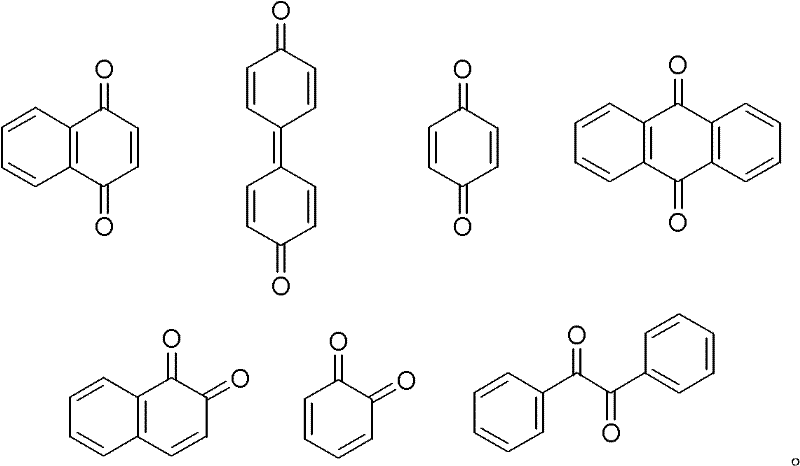

[0181] Compounds A, B, C, D and E (above) were synthesized according to the following experimental procedure and as shown in the following reaction schemes.

[0182] Nitrosylation reaction (1): (below) carried out as described in J.J.D'Amico, C.C.Tung and L.A.Walker, J.Am.Chem.Soc., 5957 (1959):

[0183]

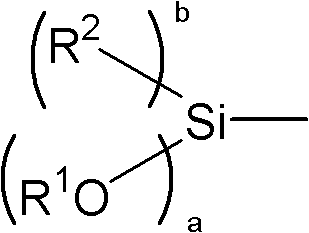

[0184] Reaction (2): Gamma-isocyanatopropyltriethoxysilane (GE Bayer Silicones A-1310) (2.35 g, 9.5 mmol) was dissolved in 10 mL of anhydrous THF in a 50 mL round bottom flask. The reaction flask was flushed with nitrogen and charged with N,N-bis-(2-hydroxyethyl)-4-nitroso-aniline (2 g, 9.5 mmol), followed by a catalytic amount of dibutyltin dilaurate (1.5 μmol ). The reaction was refluxed for an additional 2 hours under nitrogen. Isocyanate consumption was monitored using infrared spectroscopy (2275cm -1 ). The solvent was removed under reduced pressure to afford the product in quantitative yield.

[0185]

[0186] Reaction (3): Gamma-isocyanatopropyltrimethoxysila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com