Device For Machining The Narrow Surfaces Of Preferably Board-shaped Workpieces

A technology for processing workpieces and workpieces, applied in metal processing equipment, wood processing equipment, manufacturing tools, etc., can solve the problems of increasing downtime and time required, and achieve the effects of simple layout, reduced weight, and high system rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

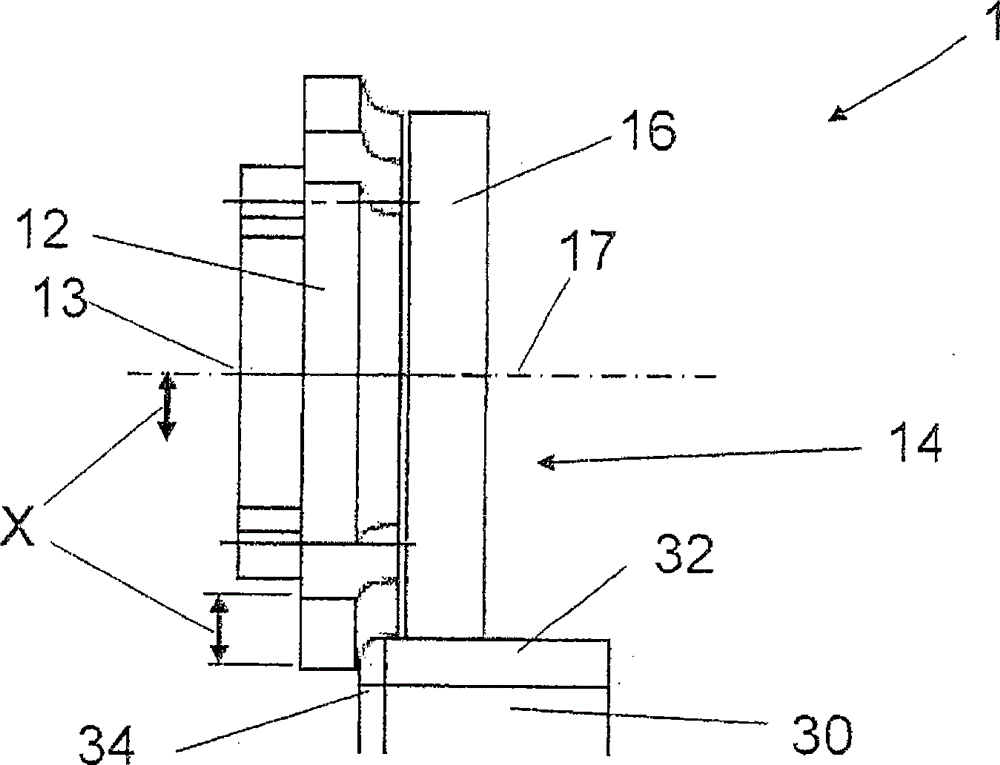

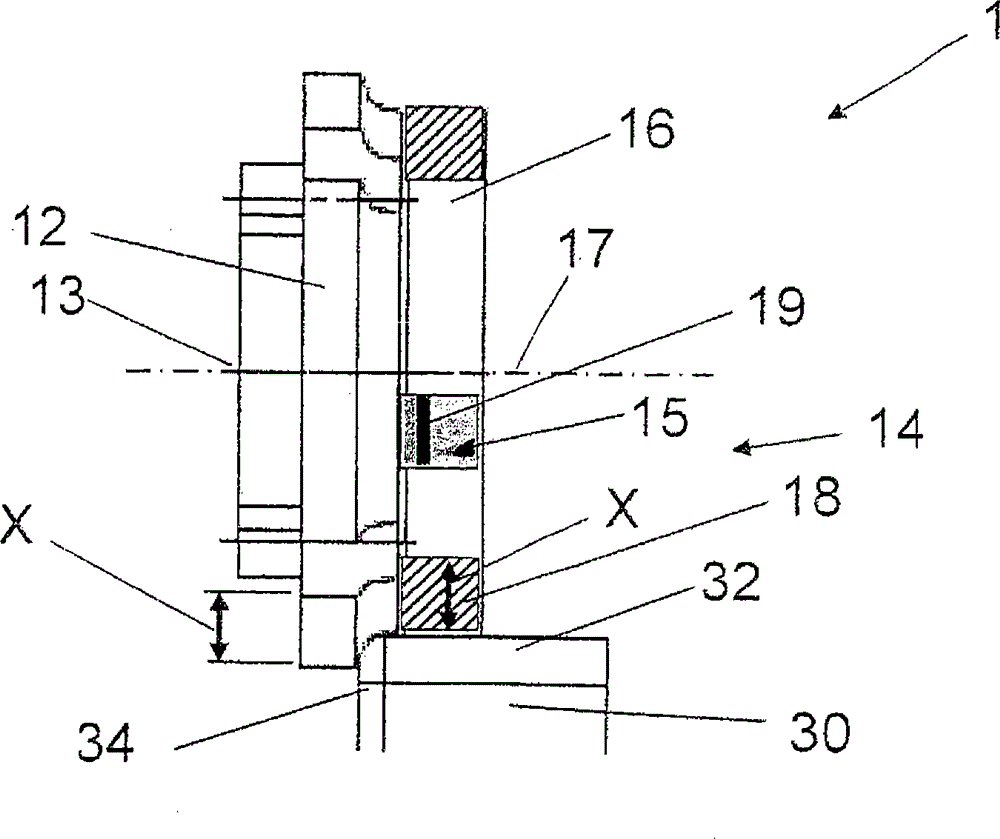

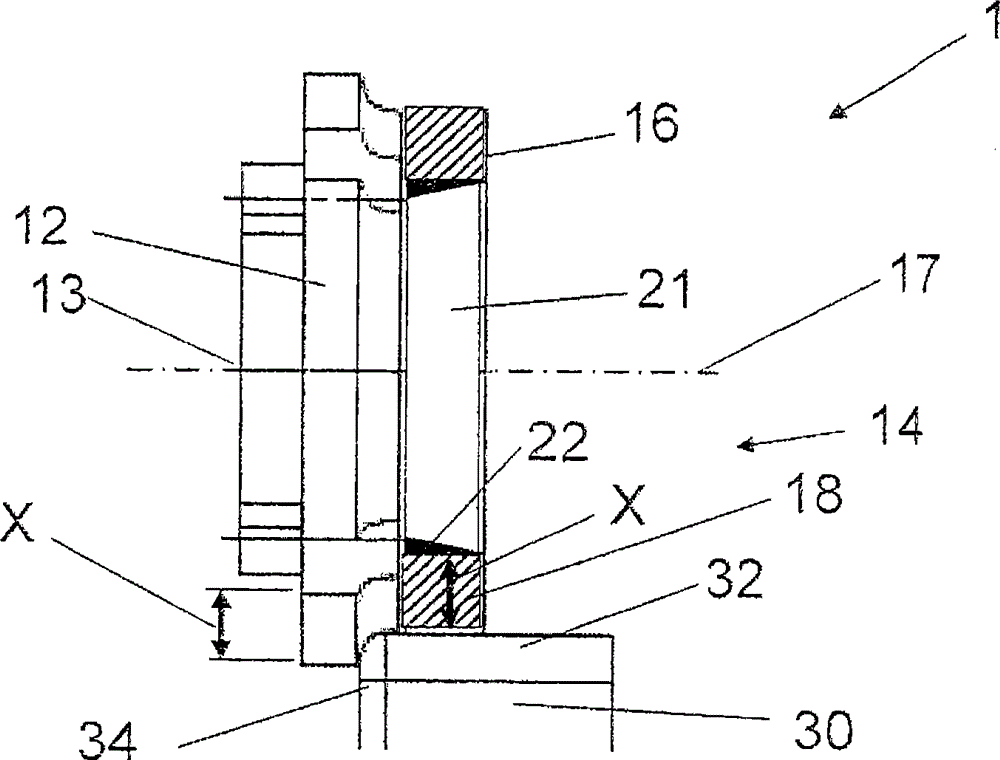

[0023] figure 1 Shows a schematic sectional view of a conventional device 1 for processing preferably floor-shaped workpieces 30 (which are preferably made at least in sections from wood, timber, plastic, etc.), with The tool 12 and the contact roller 16. The tool 12 is in this exemplary embodiment a milling cutter 12 whose axis runs horizontally in the drawing. The tool axis 13 runs on an axis of rotation 17 of a contact roller 16 of the contact device 14 arranged coaxially to the milling cutter 12 . Both the milling tool 12 and the contact rollers 16 rest on the front side on a workpiece 30 , which is shown like a rectangle.

[0024] An edge 34 is glued to the workpiece 30 on the left in the figure. The vertical elevation of edge 34 adjoining edge 32 of workpiece 30 is milled with milling cutter 12 . The axial offset of the tool is shown by the double arrow X, which is necessary in order to balance the corresponding tool wear, which is also shown by the double arrow X, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com