Device for automatically and synchronously assembling magnetic shoes and U-shaped spring of direct-current motor

A technology for direct current motors and assembly devices, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators. It can solve the problems of high labor intensity, low production efficiency, and low assembly quality, and reduce labor intensity. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention are given and described in detail below in conjunction with the accompanying drawings, so as to better understand the functions and characteristics of the DC motor magnetic tile and U spring synchronous automatic assembly device of the present invention.

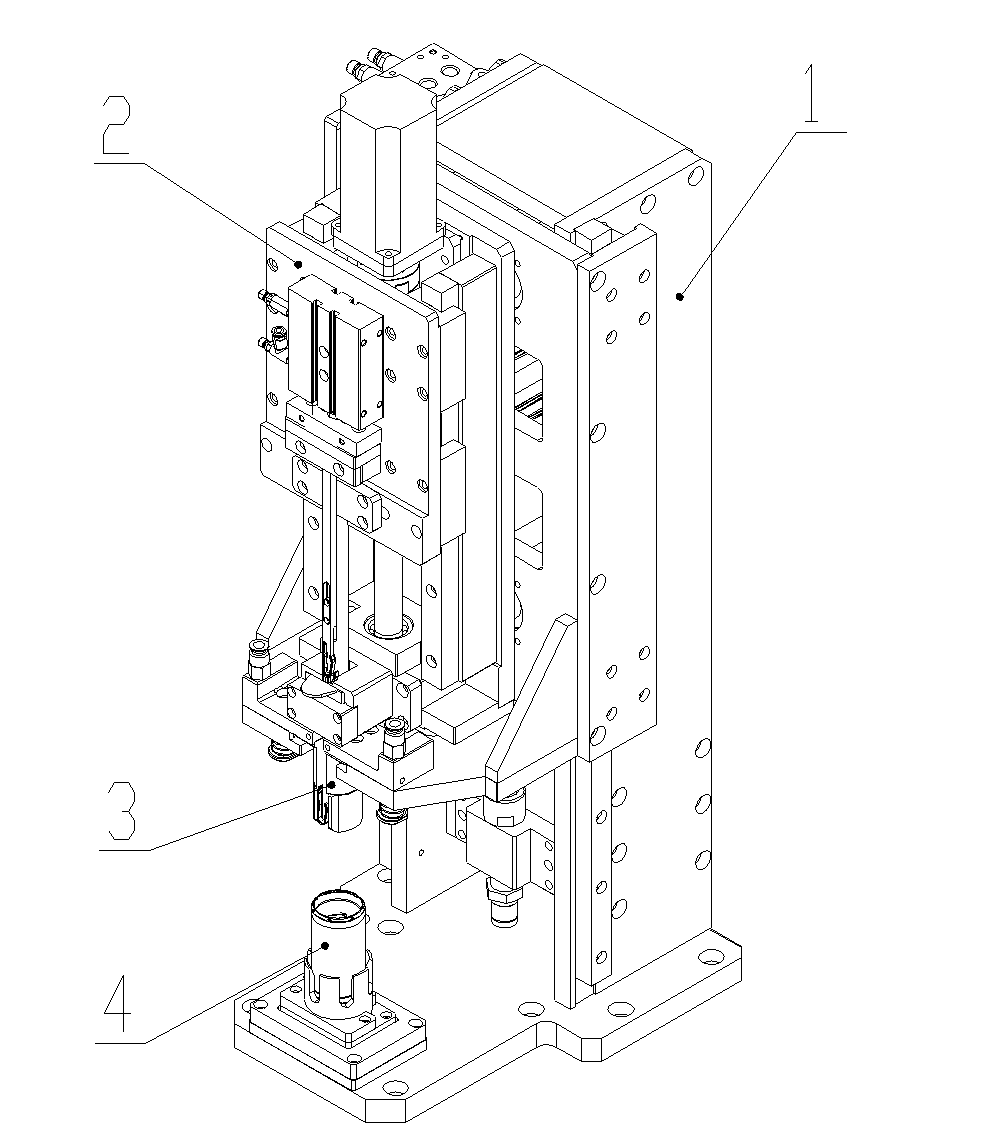

[0027] More specifically refer to the attached Figure 1-10 According to the present invention, the DC motor magnetic tile and U spring synchronous automatic assembly device includes a positioning device 1, a U spring closing device 2, a magnetic tile vacuum adsorption device 3 and a motor housing placement device 4, such as figure 1 shown.

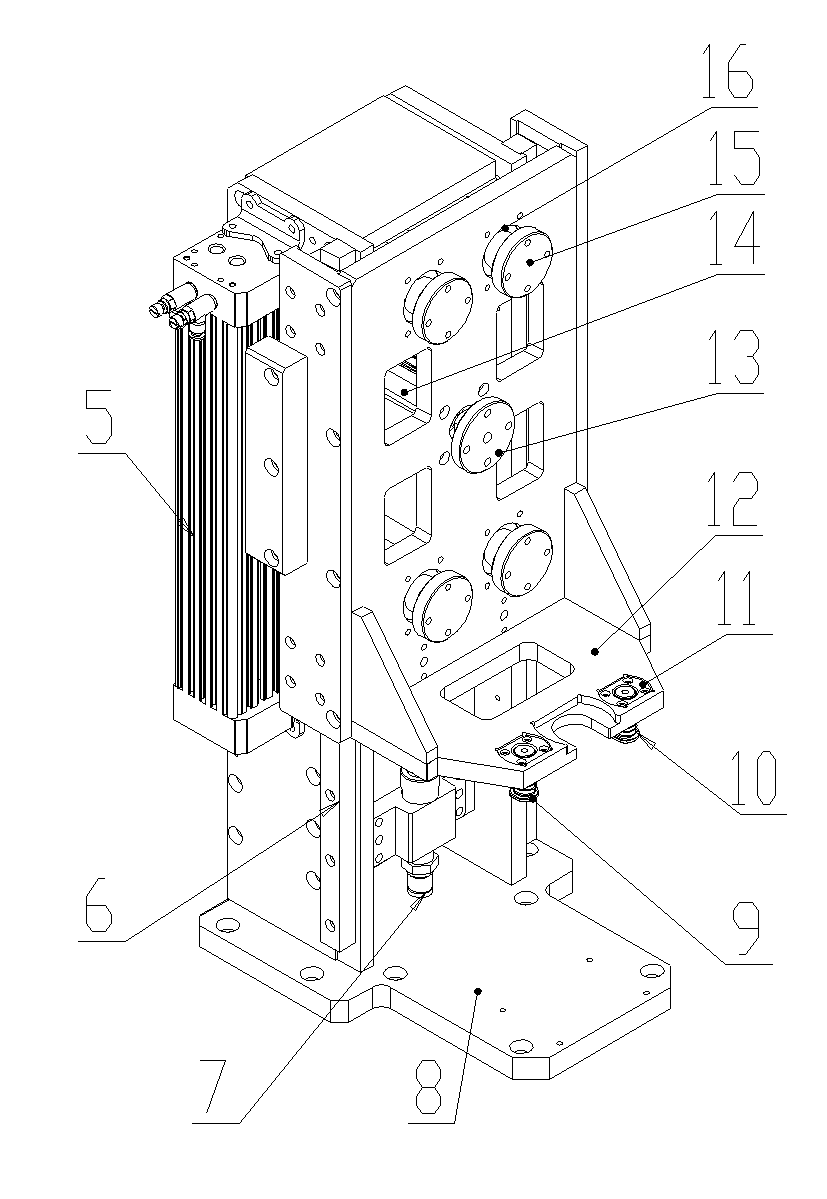

[0028] Such as figure 2 As shown, the positioning device 1 adopts a double-layer structure, and the L-shaped mounting bracket 8 is the basis of the device, and the upper and lower telescopic cylinders 5, the main guide rail 6, and the limit post 7 are fixed on its vertical surface, and there are fixed on its horizontal surface....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com