Slotless permanent magnet brushless motor structure

A permanent magnet brushless motor and motor housing technology, which is applied in the shape/style/structure of the magnetic circuit, the static parts of the magnetic circuit, and the rotating parts of the magnetic circuit, etc. Problems such as low production efficiency, to achieve the effect of reducing production difficulty, improving production efficiency, and simple winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

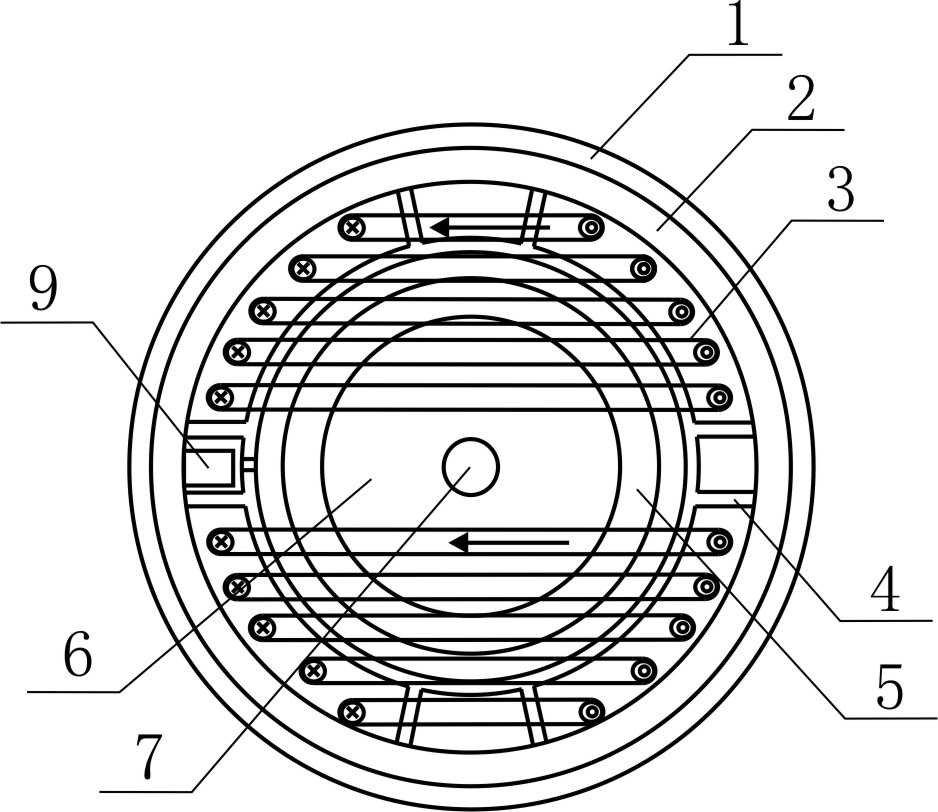

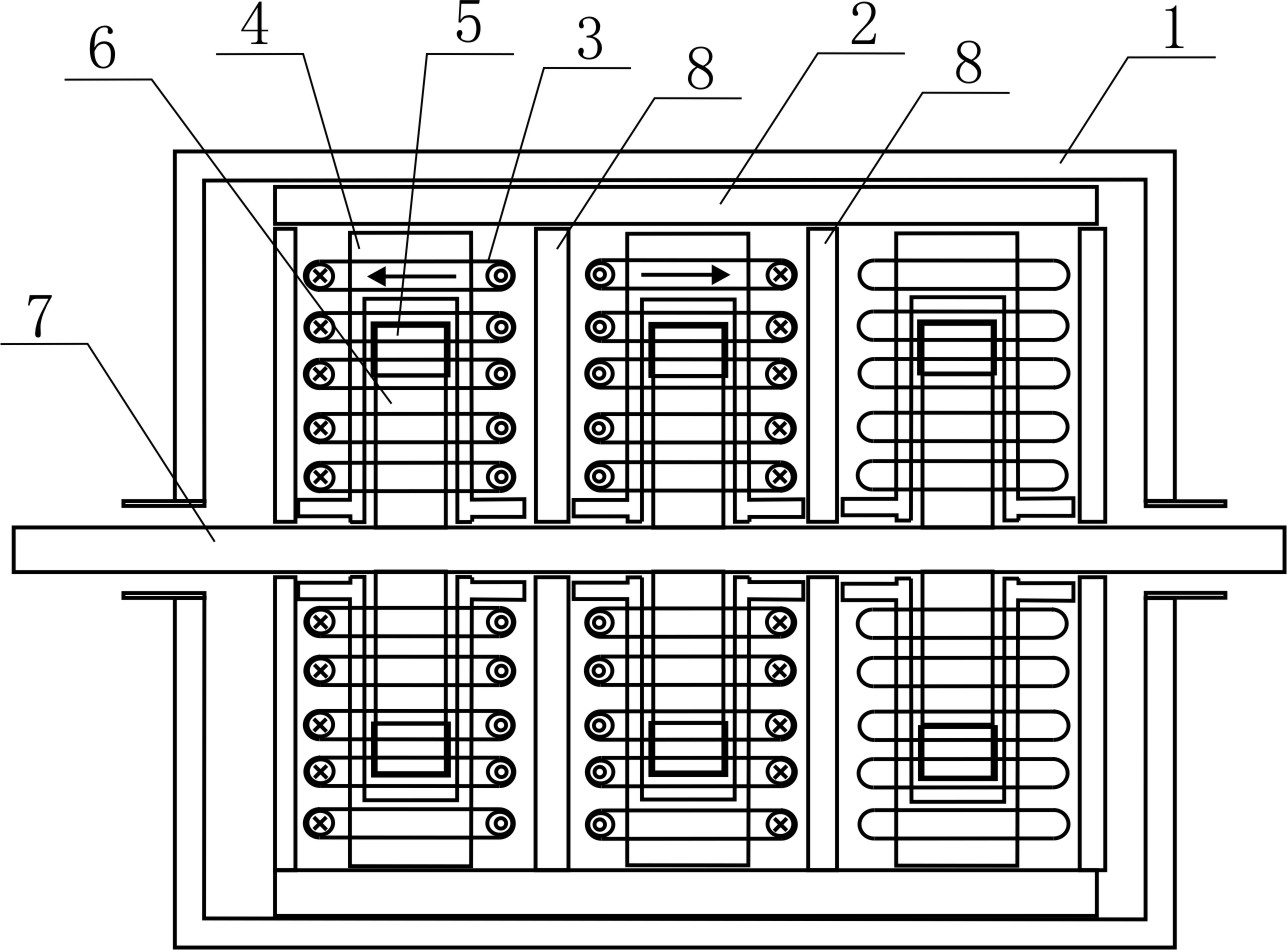

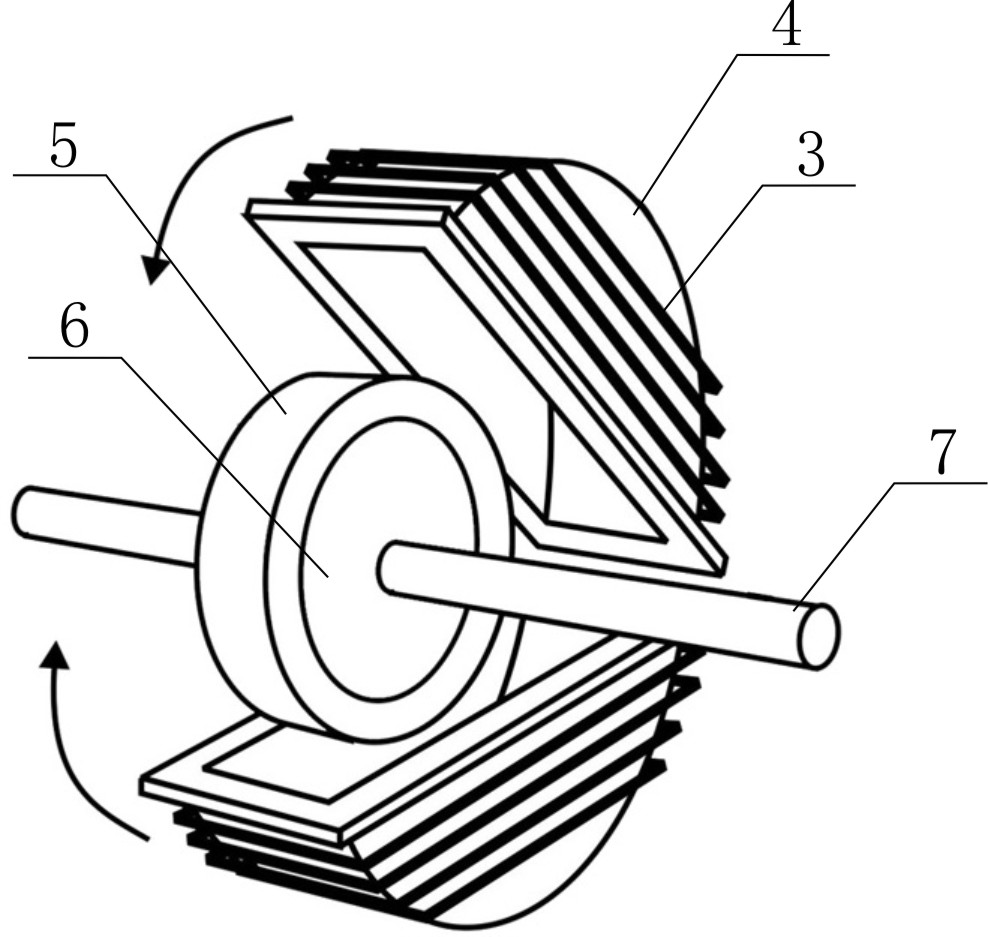

[0015] Example: such as figure 1 As shown, the three-phase motor is composed of a motor casing, a magnetically permeable ring, a wound stator, a permanent magnet rotor, silicon steel laminations and a rotating shaft from the outside to the inside. Such as figure 2 with image 3 Each wound stator shown in the figure is composed of two semicircular stator skeletons with ring windings, which can be injection molded with high temperature resistant plastic molds. The molded stator skeleton is a semicircular structure with an inner cavity, and the outer winding is wound on top of the ring. Wire. The two stator skeletons face each other to form a complete circle of a cavity. The permanent magnet rotor is wrapped in the inner cavity of the wound stator. There is a gap between the permanent magnet rotor and the stator coil, and the permanent magnet rotor can rotate in the cavity. The winding structure of the stator coil also includes a racetrack winding coil. There is a gap at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com