Fuel cell

A fuel cell and battery unit technology, applied to fuel cells, fuel cell components, circuits, etc., can solve problems such as increased usage, high unit prices of components, and large separator 1 area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

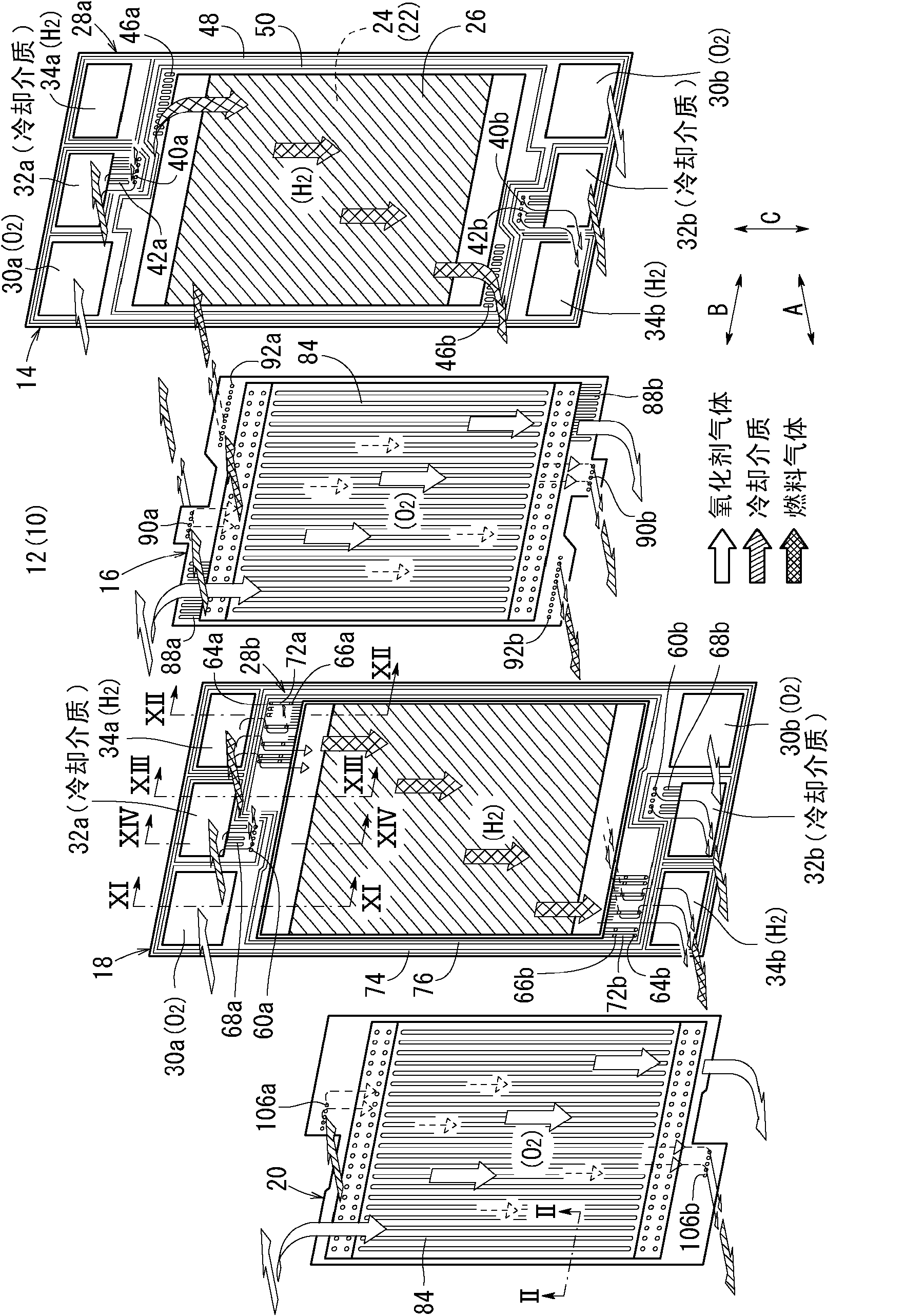

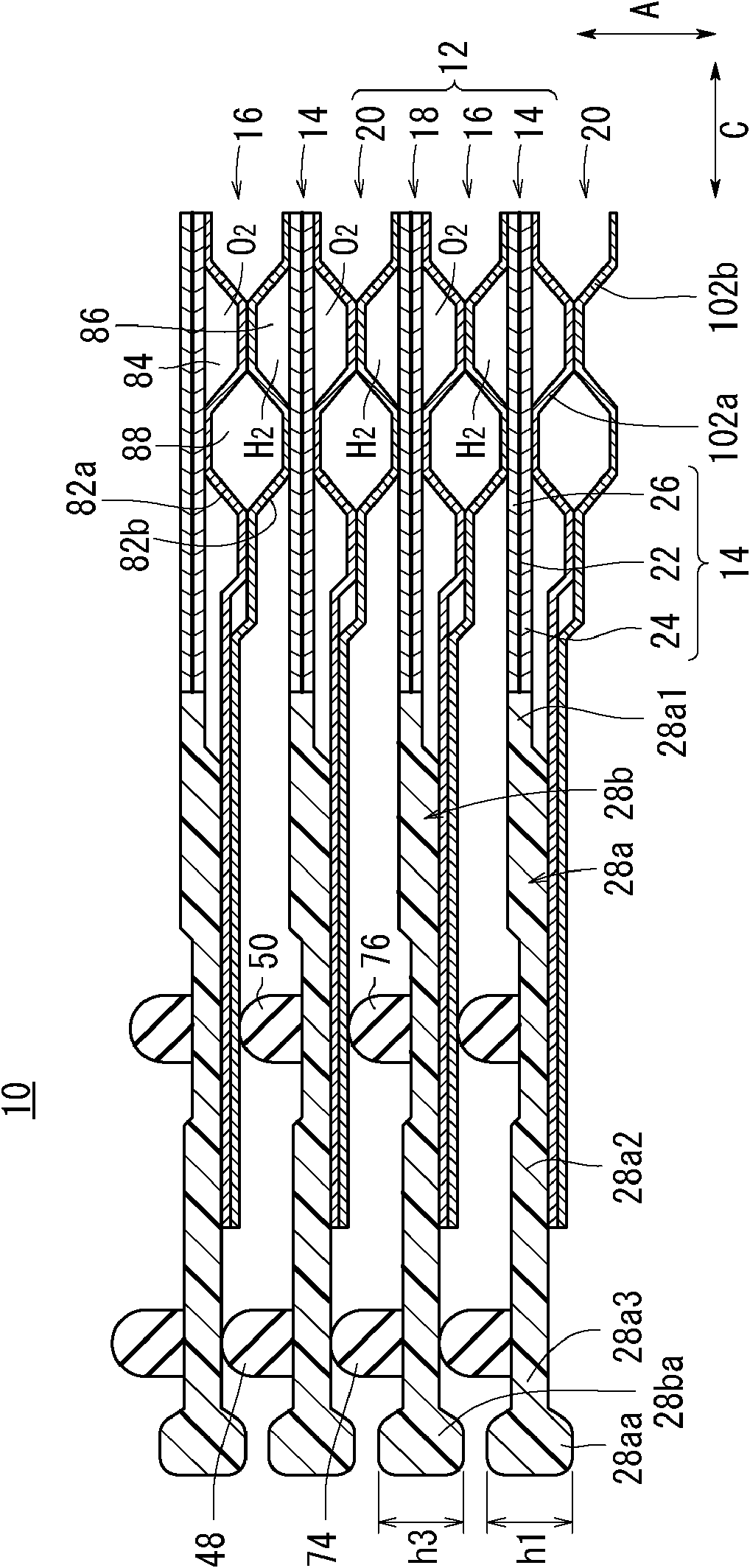

[0061] like figure 1 and figure 2 As shown, the fuel cell 10 according to the first embodiment of the present invention is constituted by stacking a plurality of battery cells 12 in the direction of arrow A (horizontal direction).

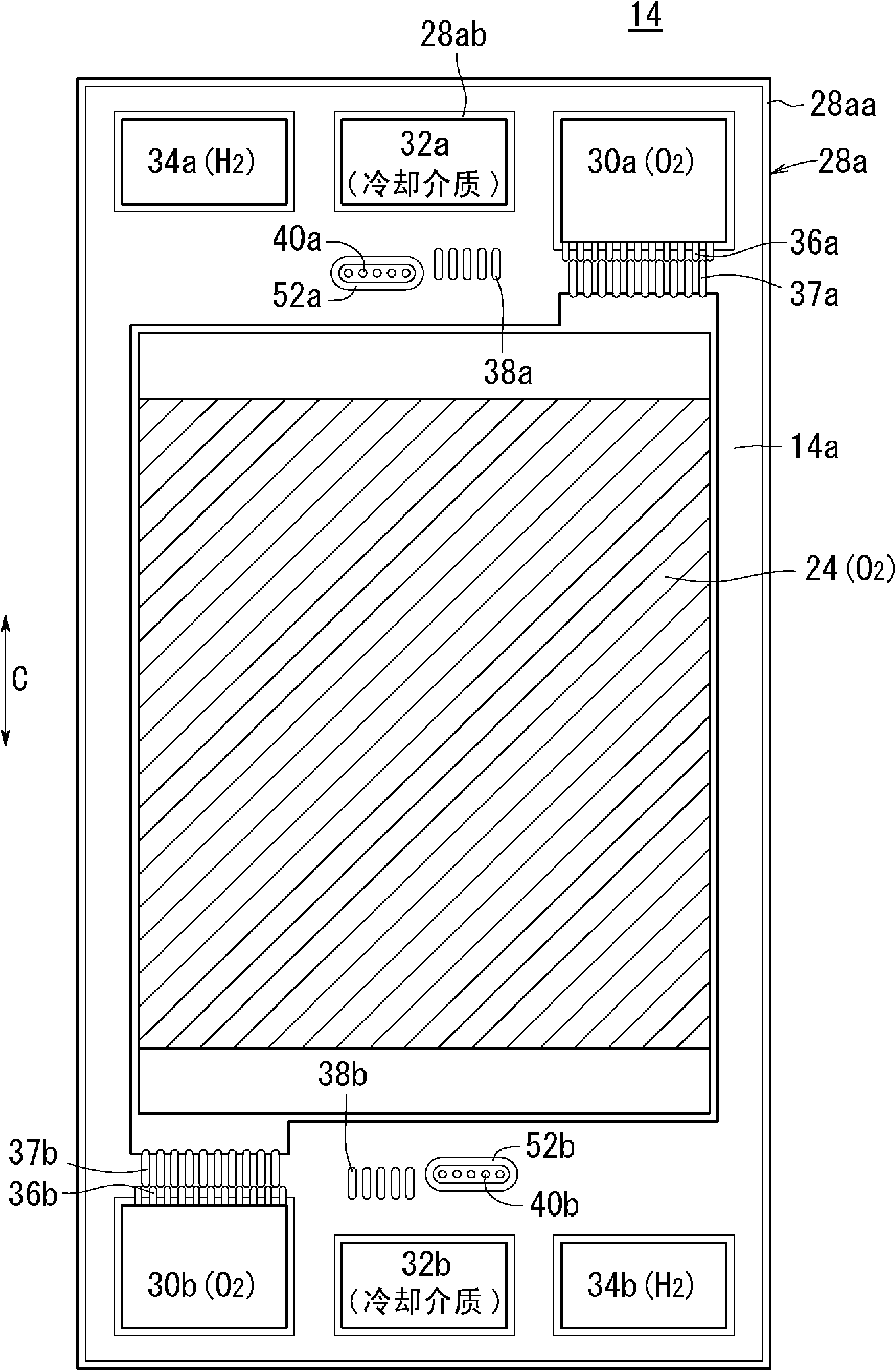

[0062] The battery cell 12 includes a first electrolyte membrane-electrode structure (electrolyte-electrode structure) (MEA) 14, a first separator 16, a second electrolyte membrane-electrode structure (electrolyte-electrode structure) (MEA) 18, and The second separator 20 . By stacking the battery cells 12, the first electrolyte membrane-electrode structure 14 is sandwiched by the second and first separators 20, 16, and the second electrolyte membrane-electrode structure 18 is sandwiched by the first and second separators. 16, 20 clamping.

[0063]The first electrolyte membrane-electrode structure 14 and the second electrolyte membrane-electrode structure 18 respectively include, for example, a solid polymer electrolyte membrane (electrolyte) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com