Photovoltaic honeycomb component module with heat collecting pipe

A technology of honeycomb components and heat pipes is applied in the field of photovoltaic heat pipe honeycomb component modules, which can solve the problems of inability to guarantee safety, increase in cost, and inability to use heat, and achieve the effects of reducing material and labor costs, enhancing reliability, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

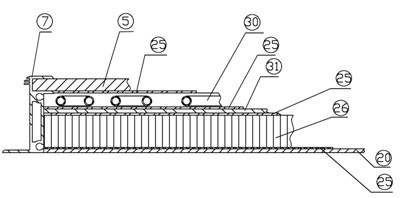

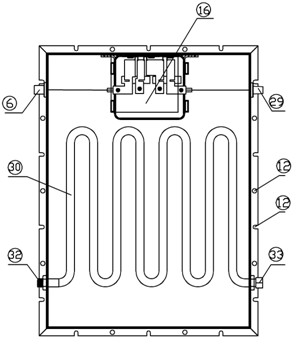

[0030] Such as Figure 1-4 As shown, it includes a photovoltaic module composed of a photovoltaic panel 5, a connector and a junction box 27. The lower layer of the photovoltaic panel 5 is a solar heat collector 30, an aluminum honeycomb core 26, and a back aluminum plate 20 (rust steel plate can also be used). The main structure of the component module is formed by bonding the hot-melt adhesive film 25 ; the aluminum alloy frame 7 is arranged around the main structure of the component module; the aluminum alloy frame 7 is provided with an installation hole 12 . The connectors are the positive connector 6 and the negative connector 29, and the two ports of the solar collector tube 30 are provided with a collector tube outlet joint 32 and a heat collector tube inlet joint 33, which are respectively located on both sides of the component module; the junction box is built into the honeycomb core layer middle.

[0031] Two layers of hot-melt adhesive films 25 are arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com