Method for quickly and efficiently detecting content of trace elements in quartz sand through microwave digestion

A technology of microwave digestion for medium and trace elements, which is applied in the preparation of test samples, color/spectral characteristic measurement, etc., and can solve problems such as environmental pollution, expensive testing instruments, and complicated operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

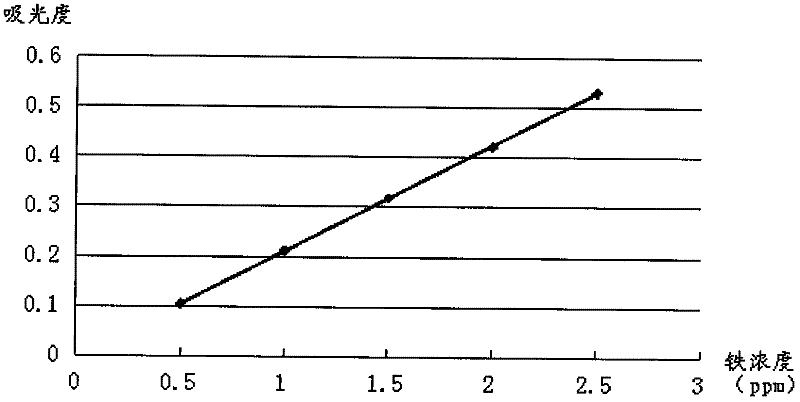

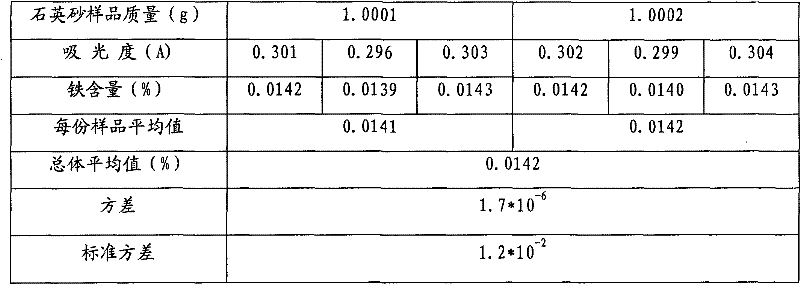

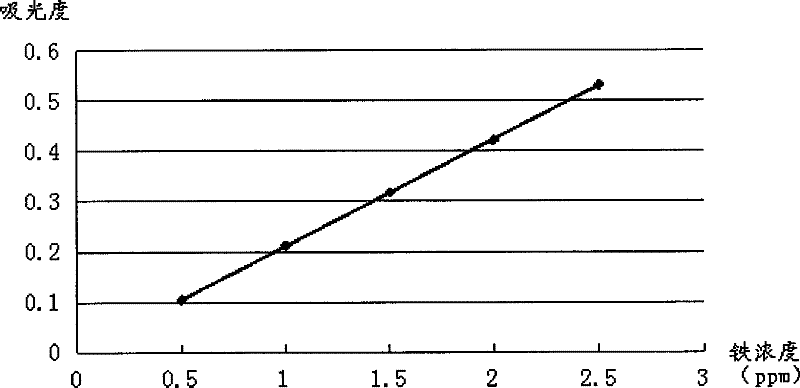

Image

Examples

Embodiment 1

[0017] Accurately weigh about 0.3g of quartz sand into the sample-dissolving cup of the microwave digestion tank, add 1.5g of HF and 0.07g of nitric acid solution, use a flarer to expand the lid of the sample-dissolving cup and slowly cover the sample-dissolving cup vertically Keep the cup tightly sealed.

[0018] Put the sample dissolving cup into the digestion tank, cover the digestion tank, put it into the microwave digestion instrument, set the digestion time, preset pressure and other microwave digestion conditions according to the operation requirements, as shown in the table below,

[0019] Work step

Preset pressure (MPa)

running time (min)

Real-time pressure (MPa)

1

0.2

3

0.2

2

0.4

3

0.4

3

0.6

3

0.6

4

0.8

3

0.8

5

1.0

3

1.0

6

1.2

3

1.2

7

1.5

3

1.5

[0020] Start t...

Embodiment 2

[0023] Accurately weigh about 0.3g of quartz sand and put it into the sample dissolving cup of the microwave digestion tank, add 6g of HF and 0.2g of nitric acid solution, and the others are the same as in Example 1.

Embodiment 3

[0025] Accurately weigh about 0.3g of quartz sand and put it into the sample dissolving cup of the microwave digestion tank, add 3g HF and 0.12g nitric acid solution, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com