Method for determining stability of PVC heat stabilizer

A heat stabilizer and stability technology, applied in the detection field, can solve the problems of inability to make judgments on the change trend and process of stabilizer stability, troublesome instrument cleaning, and time-consuming, etc., to achieve easy promotion, simple evaluation method, and operation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the formula 100g DG-800PVC resin powder (brand name of Tianjin Dagu Chemical Industry), 6.2g additives (including: 0.4g pentaerythritol adipate, 0.5g methyl methacrylate and acrylate copolymer, 4g methyl methacrylate -butadiene-styrene copolymer, 0.8g fatty acid pentaerythritol ester), 1g mercaptan methyl tin stabilizer (sample one), stir on the mixer for 20s, weigh 65g in a weighing cup. The rheometer experiment can be started when the temperature of the torque rheometer (XSS-300 rheometer, Shanghai Kechuang Rubber and Plastic Machinery Equipment Co., Ltd.) is stable, and the material is pressed into the mixing device, and the rheometer software displays When the time reaches 3 minutes, use tweezers to pick up a little PVC melt in the mixing device, put it into the pliers pressing groove and quickly press the pliers to cool and form the melt, and use scissors to remove the overflowing edge around the circular sample. After that, the material was taken ever...

Embodiment 2

[0033] The methyl tin mercaptide stabilizer (sample one) in Example 1 is replaced with a polyester tin stabilizer (sample two), and the other testing methods are the same as in Example 1. The measured B values are shown in Table 1.

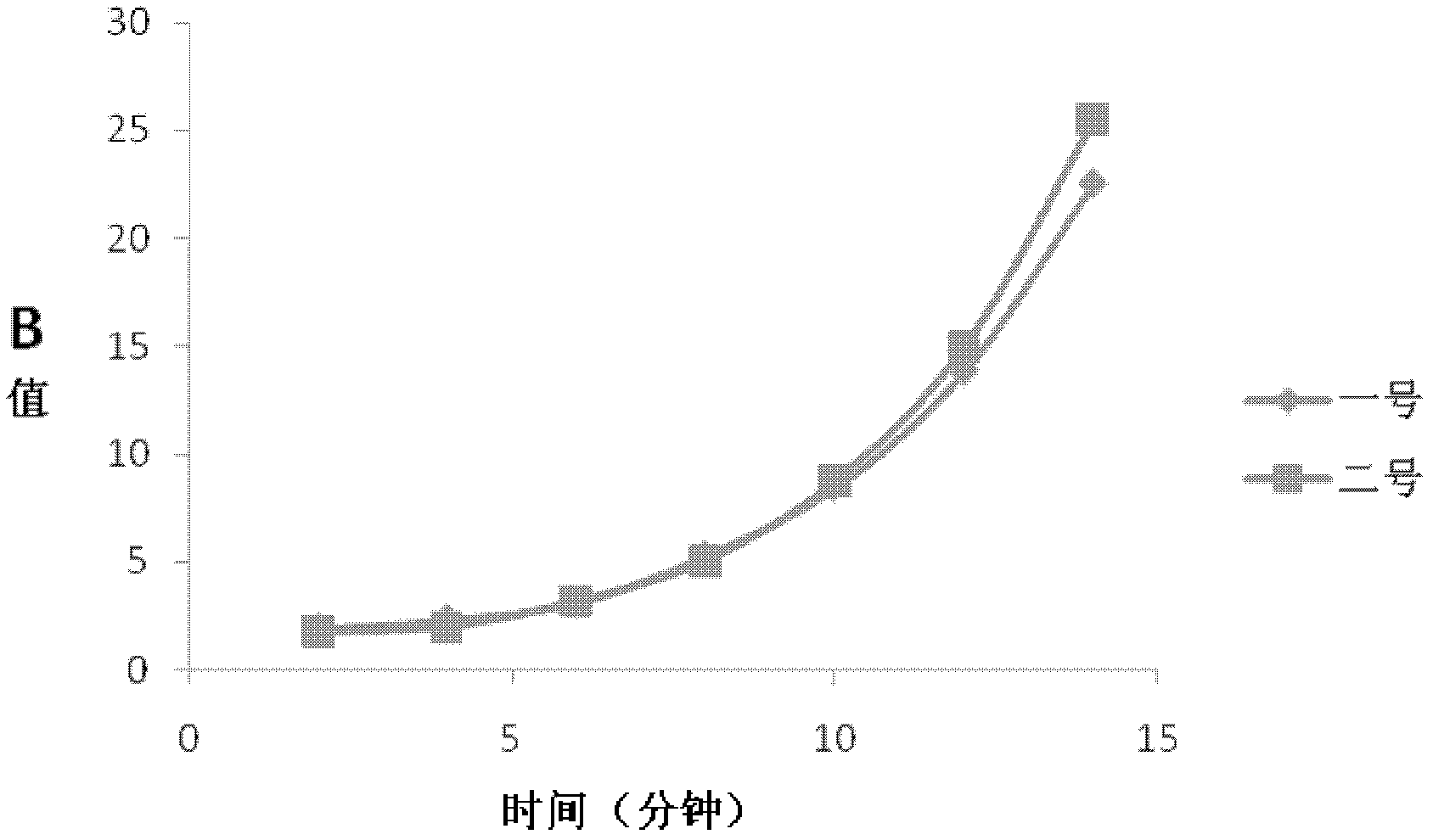

[0034] In addition, the B value that embodiment 1 and embodiment 2 measure is made B value-time schematic diagram, as figure 1 shown.

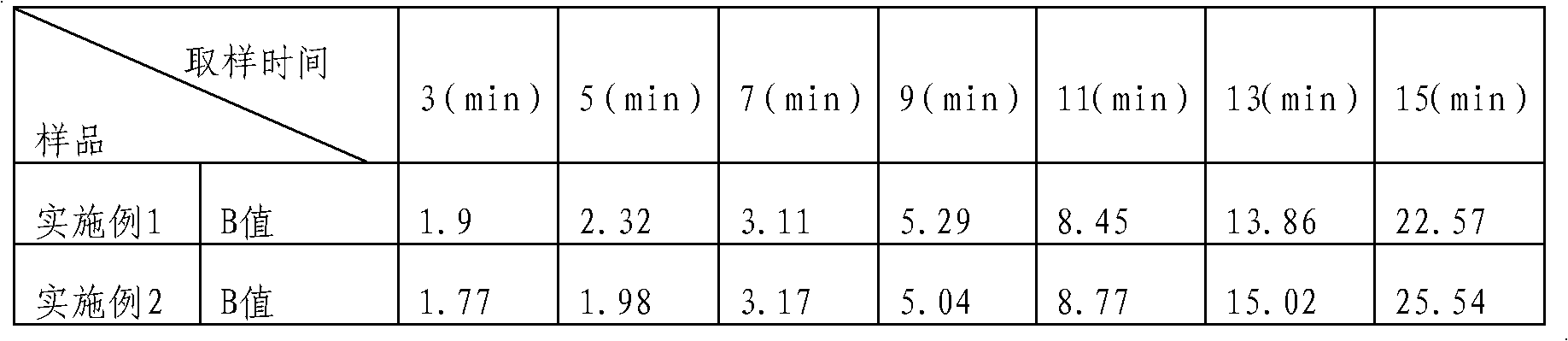

[0035] The B value that records in table 1, embodiment 1 and embodiment 2

[0036]

[0037] as table 1 and figure 2 As shown, the B values of sample 1 and sample 2 both increased with time, and the stability of sample 1 and sample 2 decreased with time, and the B value of sample 1 when sampling at 3min and 5min The value of B is greater than that of sample two, and the B value after 5 minutes is smaller than that of sample two. It can be concluded that the initial stability of sample one is better than that of sample two, but its long-term stability is worse than that of sample two.

Embodiment 3

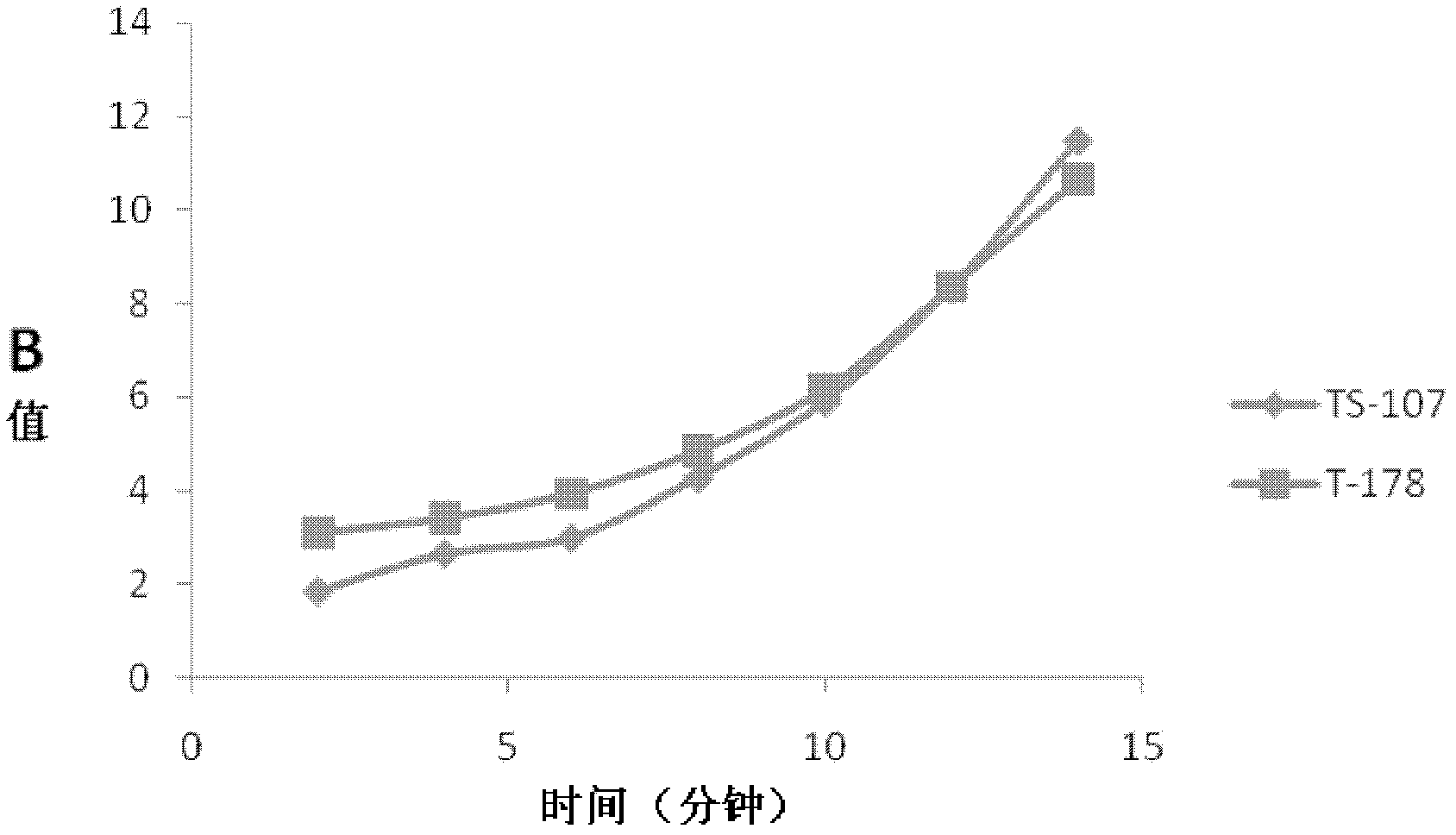

[0039] According to the formula, 100g DG-1000PVC resin powder (brand name of Tianjin Dagu Chemical Industry), 12.3g additives (including: 0.3g polyethylene wax, 1g titanium dioxide, 0.1g oxidized polyethylene wax, 0.6g paraffin wax, 0.3g calcium stearate , 10g calcium carbonate), 6g reverse ester tin stabilizer TS-107 (produced by Hubei Hoko Star Chemical Industry) batching, stirred on the mixer for 45s, weighed 65g in the weighing cup. The rheometer experiment can be started when the temperature of the torque rheometer (XSS-300 rheometer, Shanghai Kechuang Rubber and Plastic Machinery Equipment Co., Ltd.) is stable, and the material is pressed into the mixing device, and the rheometer software displays When the time reaches 4 minutes, use tweezers to pick up a little melt in the mixing device, put it into the pliers pressing groove and quickly press the pliers to cool and form the melt, use scissors to remove the overflowing edge around the circular sample, and then The mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com