Method for evaluating acoustical quality of ship and warship mechanical system according to effective power

A technology of mechanical system and acoustic quality, applied in the direction of ships, ship components, ship construction, etc., can solve the problems of estimation, inability to conduct vibration and noise of mechanical systems, lack of evaluation of acoustic quality of mechanical systems, etc., to achieve good operability and evaluation principles. Clear, easy-to-assess results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

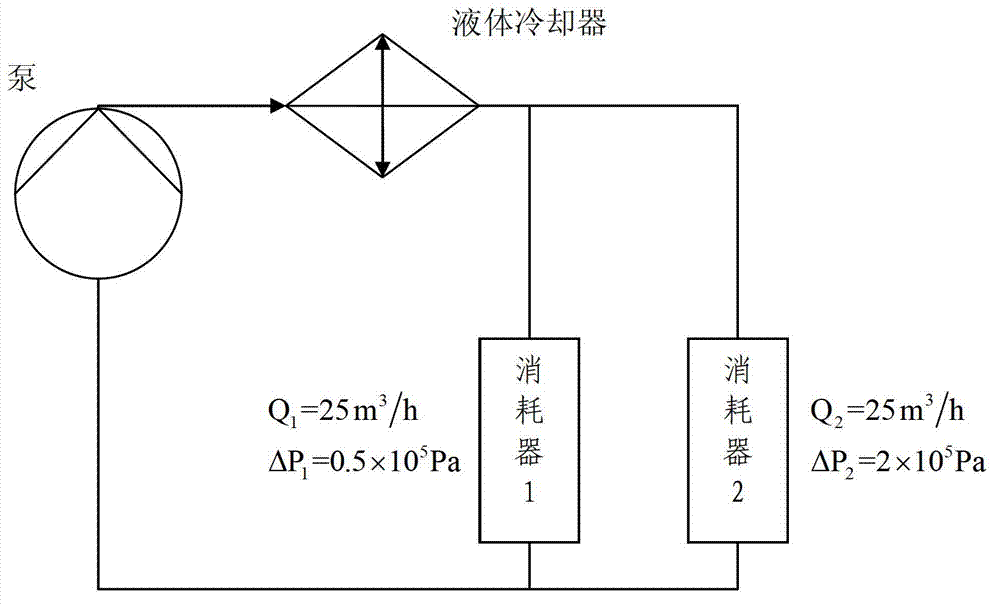

[0063] The following uses the efficiency parameter K of the pipeline transmission system N and B S , to specifically evaluate the acoustic quality of a typical ship cooling system.

[0064] Assuming that all consumers of the cooling system are connected in parallel, they are located between the inlet and outlet main lines, in which case the main lines act as collectors, each of which is kept at constant pressure. For simplicity, a water cooling system for two consumers is studied, the original functional scheme of this cooling system is shown in Figure 4 As shown, the nominal diameter of the transmission pipe supplying cooling water to each consumer is D y 100mm. The first consumer takes 25m under normal function 3 / h, its pressure loss is 5×10 4 Pa (5m water column), the second consumer also needs 25m 3 / h, but its head loss is 2×10 5 Pa (20m water column), the initial function scheme of the system is as follows image 3 .

[0065] In order to guarantee these parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com