Method for predicting rubber storage life on basis of compression stress relaxation test equipment

A technology for testing equipment and compressive stress, which is applied in the direction of applying stable tension/pressure to test the strength of materials, so as to improve work efficiency, ensure accuracy and repeatability, and avoid temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

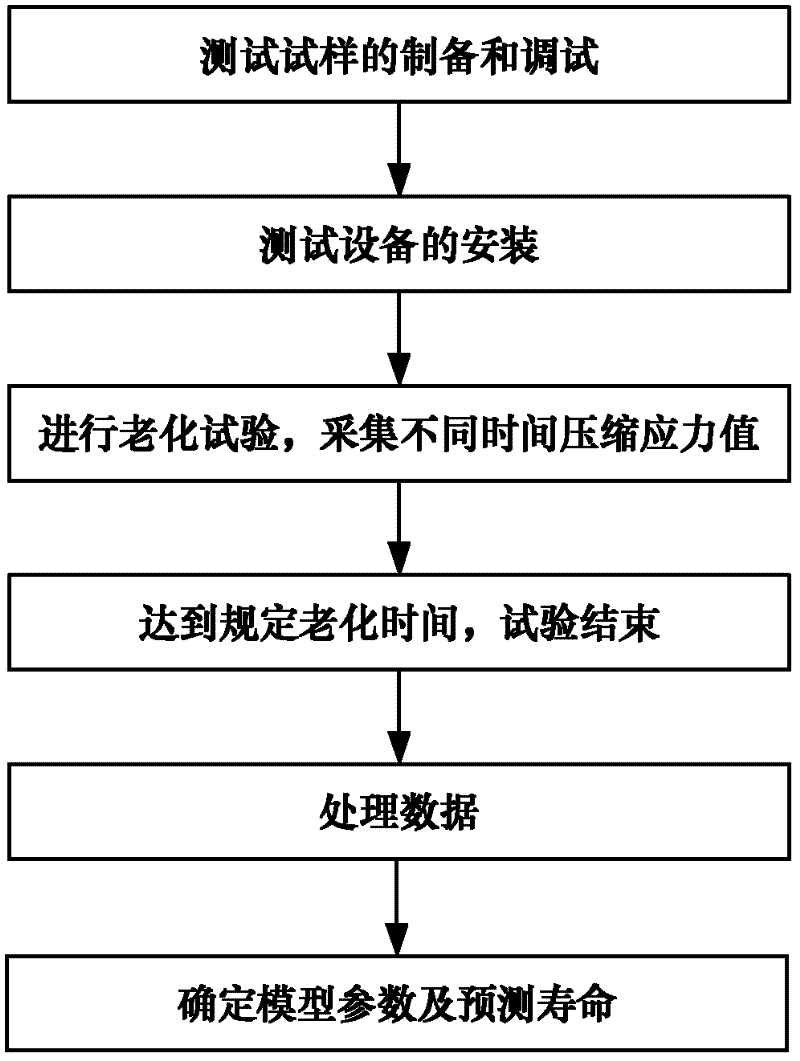

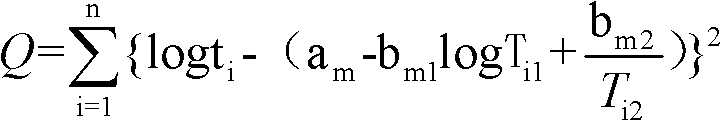

Method used

Image

Examples

Embodiment Construction

[0025] The testing equipment provided in the present invention can also be used to test the compression set in rubber aging tests at room temperature and high temperature, so as to explore the relationship between compression stress relaxation and compression set. In addition, the device of the present invention can also be equipped with several strain gauges to measure the stress-strain relationship at different positions of the same sample, so as to reduce the error caused by a single measurement.

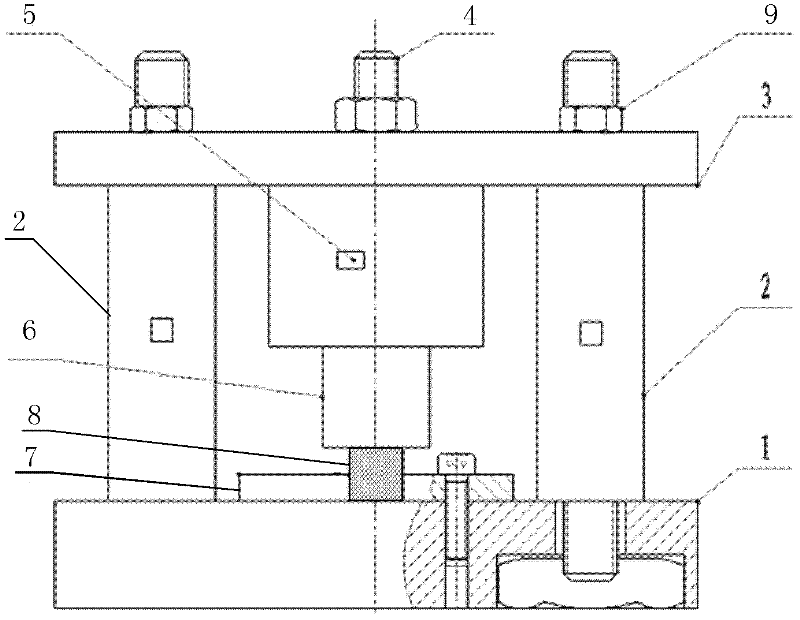

[0026] The test equipment used is as figure 1As shown, it mainly includes: lower plate 1, limiter 2, upper plate 3, pressure sensor 4, sensor lead wire 5, pressure head 6 and flange 7. The upper plate 3 is placed above the lower plate 1, the lower plate 1 is vertically corresponding to the central position of the upper plate 3, and the central position of the upper plate 3 is provided with a central through hole, each of which is symmetrical to the left and right of the central t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com