Convex aspheric optical element surface type detection device

An optical element, surface detection technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inability to accurately measure the surface of convex aspheric optical components, and inability to ensure that the surface to be measured is perpendicular to the light source, etc. Simple structure, high positioning accuracy, and the effect of reducing positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments will further illustrate the technical solution of the present invention in conjunction with the accompanying drawings.

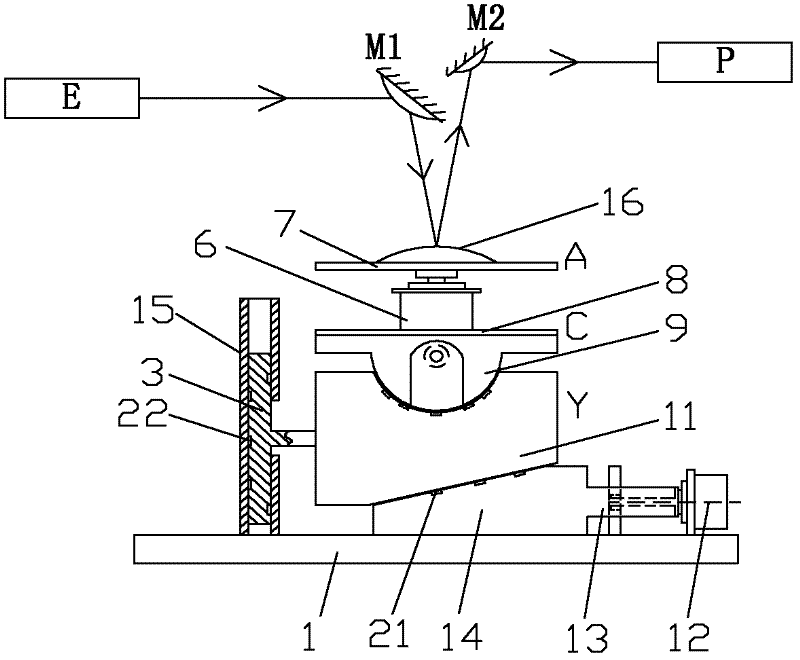

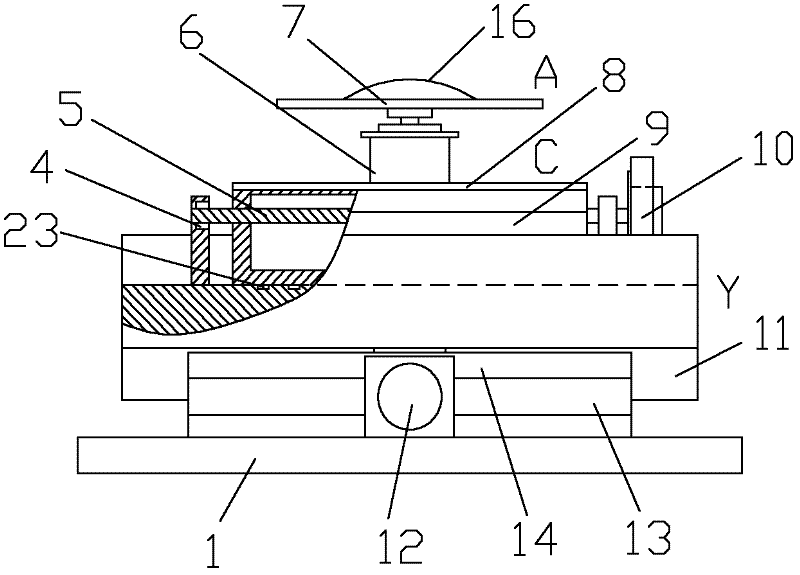

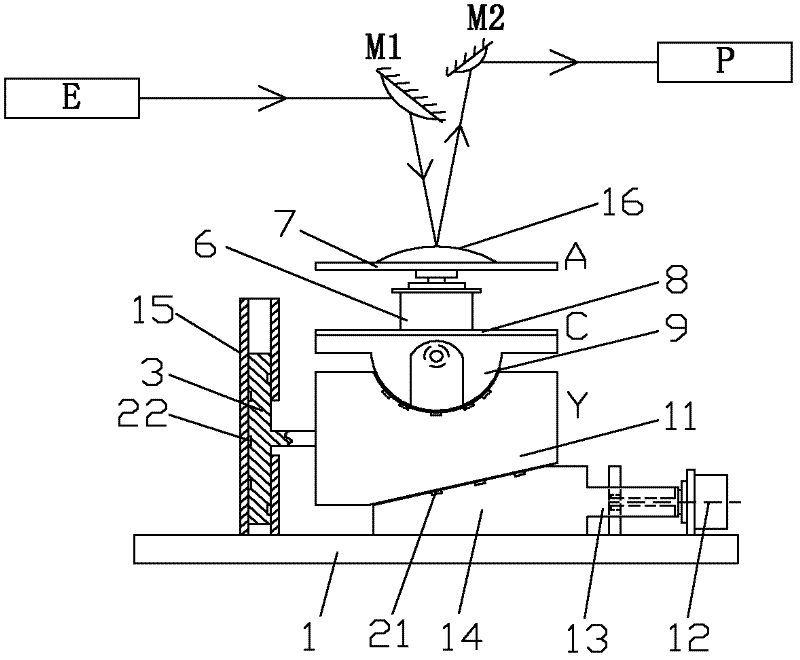

[0022] Such as figure 1 , 2 As shown, the embodiment of the present invention is provided with a light source E, a reflector M1, a receiver mirror M2, a detection platform, a lifting platform 11 and an analysis and processing system P. Among them, the detection platform is equipped with three parts: vertical motion mechanism, swing mechanism and rotary mechanism.

[0023] The vertical motion mechanism is provided with a base 1 , a first support oil chamber 21 , a lifting rod 3 , a screw motor 12 , a connecting plate 13 , a trimming wedge 14 and a limit groove 15 . The fine-tuning wedge 14 is located on the base 1, the connecting plate 13 is fixed on the fine-tuning wedge 14, and the connecting plate 13 is connected with the screw motor 12 through a ball screw. Lifting platform 11 is supported by fine-tuning wedges 14, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com