Panel spliced type backlight module

A technology of backlight module and jigsaw panel, applied in optics, light guide, electric light source, etc., can solve the problems of difficult thinning, heavy quality, high cost, etc., and achieve the effect of thinning design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

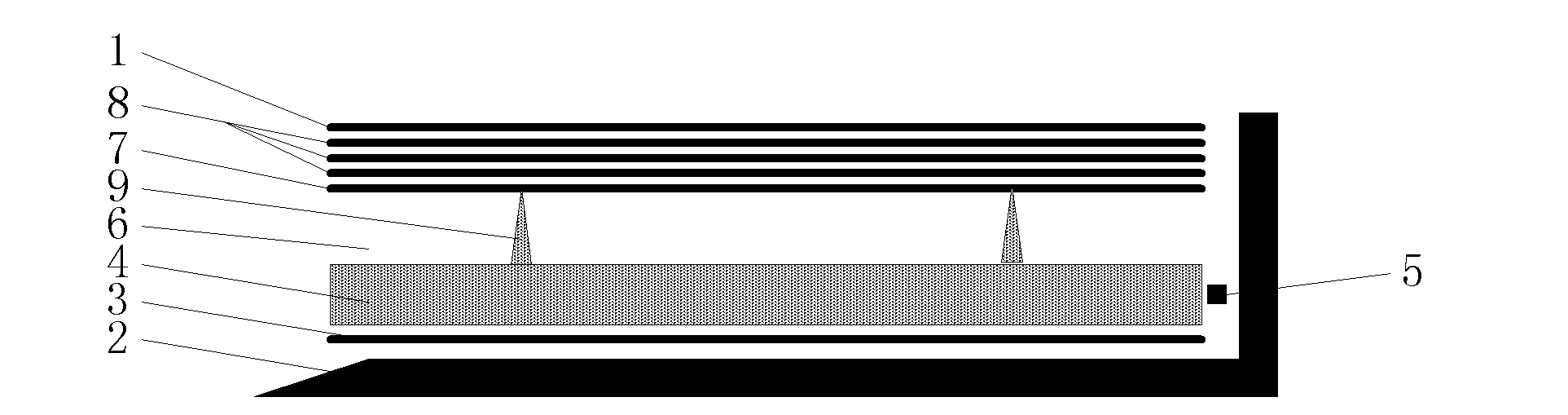

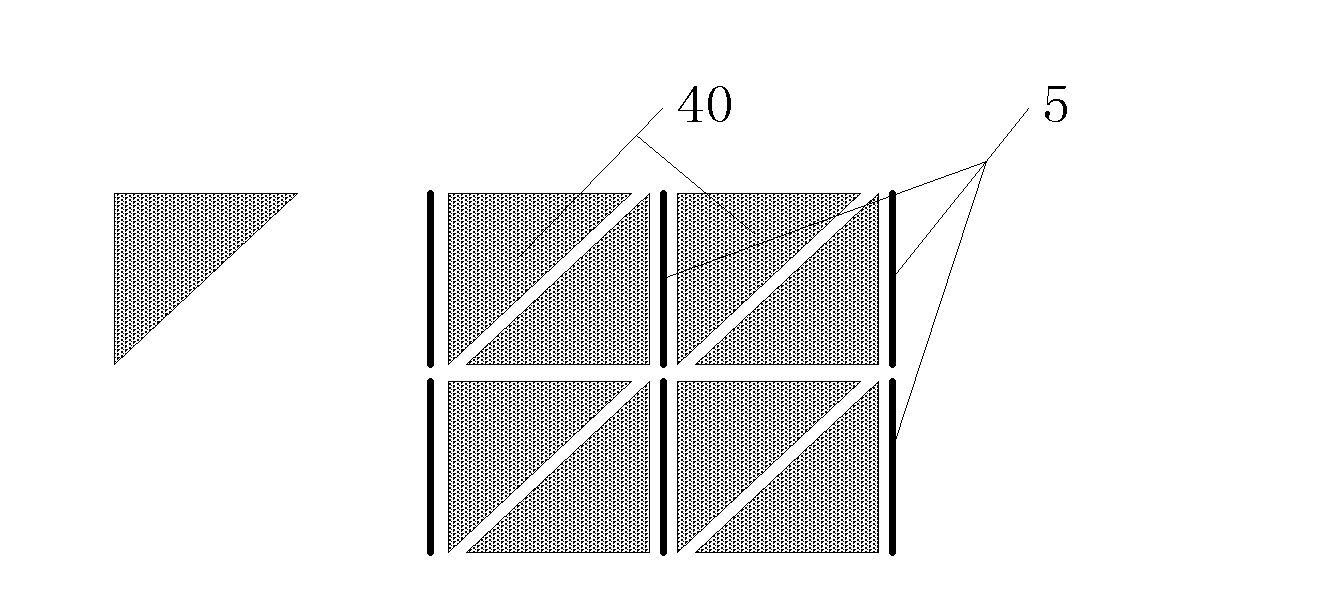

[0023] like figure 1 As shown in or 2, a panel-type backlight module of the present invention, which forms a large-scale thin liquid crystal display with a liquid crystal module 1, which sequentially includes a backplane 2, a reflector 3, a light guide module 4, a light source 5, a light mixing Space 6, diffuser plate 7 and optical film 8, more than two support positioning columns 9 are arranged between light guide module 4 and diffuser plate 7, light guide module 4, support positioning column 9, diffuser plate 7 and optical film 8 Fixed on the back plate 2, the optical film 8 is attached to the diffuser plate 7, the light guide module 4 is composed of two or more light guide plates 40, and the light source 5 is arranged outside the light guide plate 40 or two light guide plates Between 40.

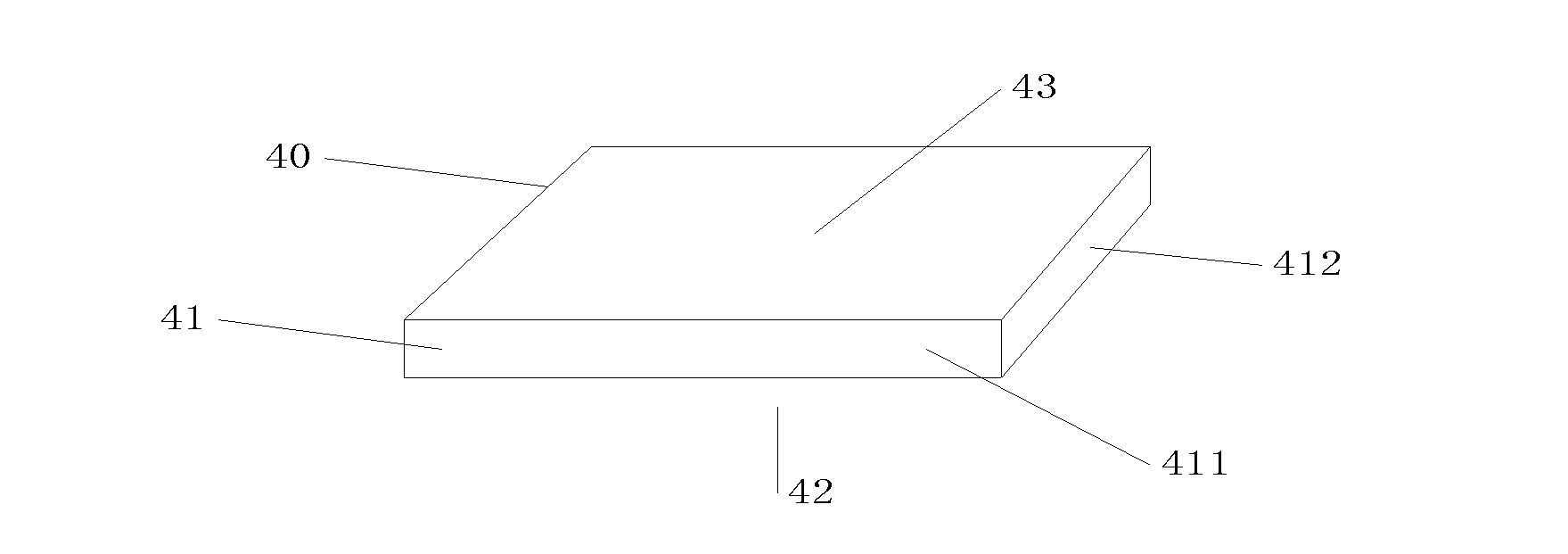

[0024] like figure 2 As shown, the light guide plate 40 includes a vertical surface 41, a reflective surface 42, and a light-emitting surface 43. The reflective surface 42 is parallel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com