Scraping-rolling machine boring rod spiral sealing mechanism and scraping-rolling machine

A technology of screw sealing and boring bar, applied in the field of screw sealing mechanism of rolling scraper boring bar and scraping rolling machine, can solve the problems of poor sealing, pollution, affecting the normal operation of machine tools, etc., to facilitate replacement and assembly operations, and to promote Easy and fast application and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but it is only a preferred embodiment and is not used to limit the essential scope of the present invention.

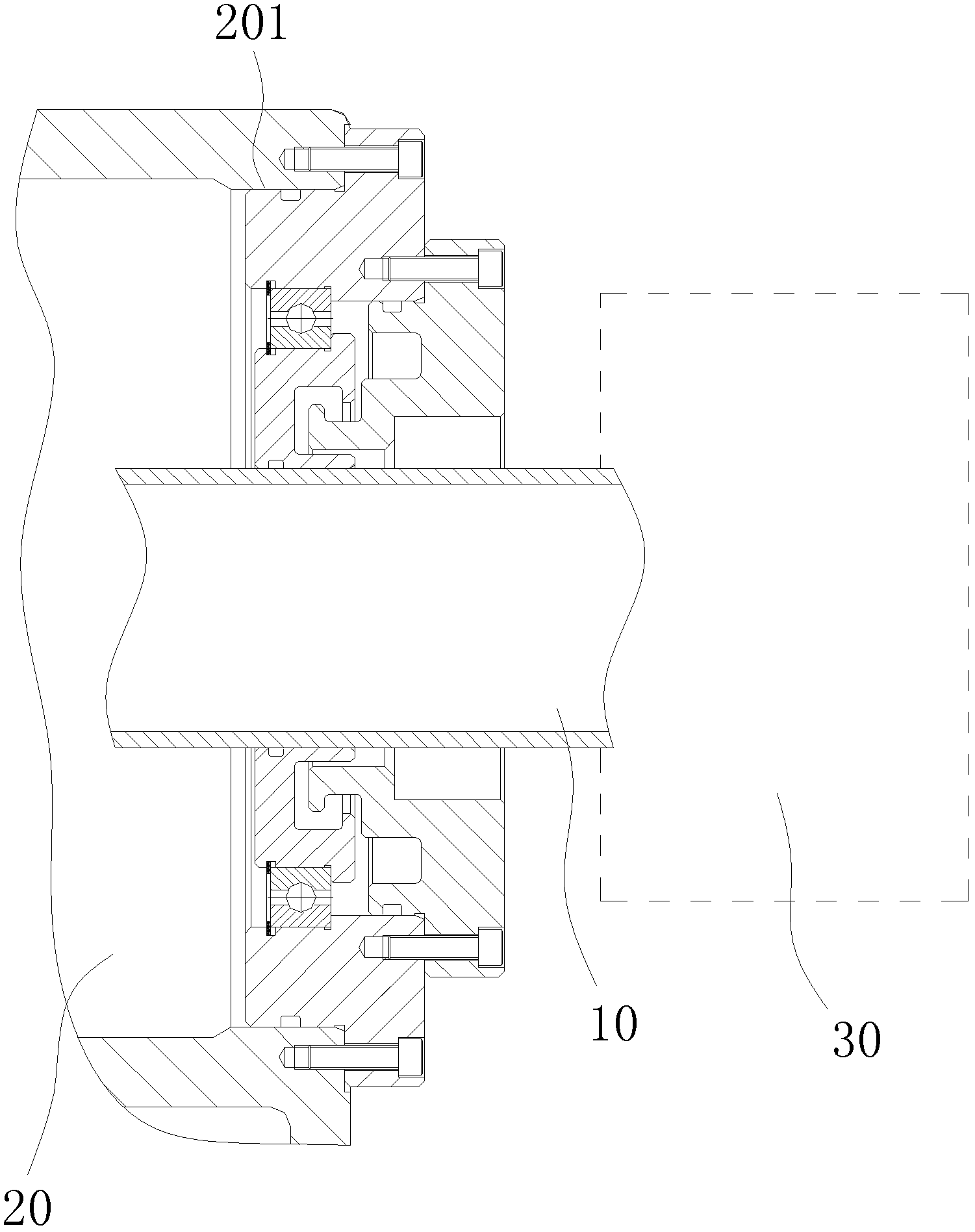

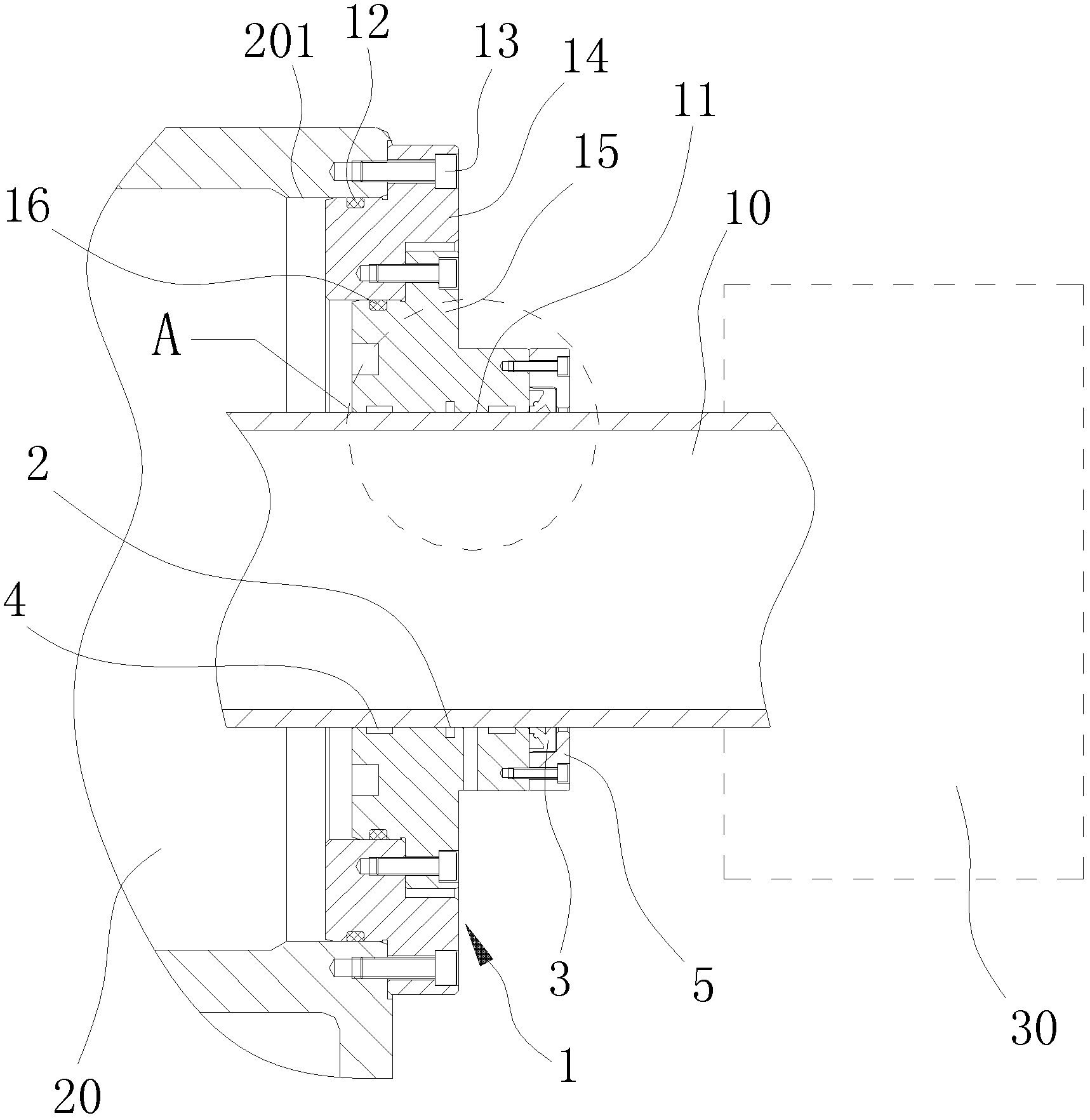

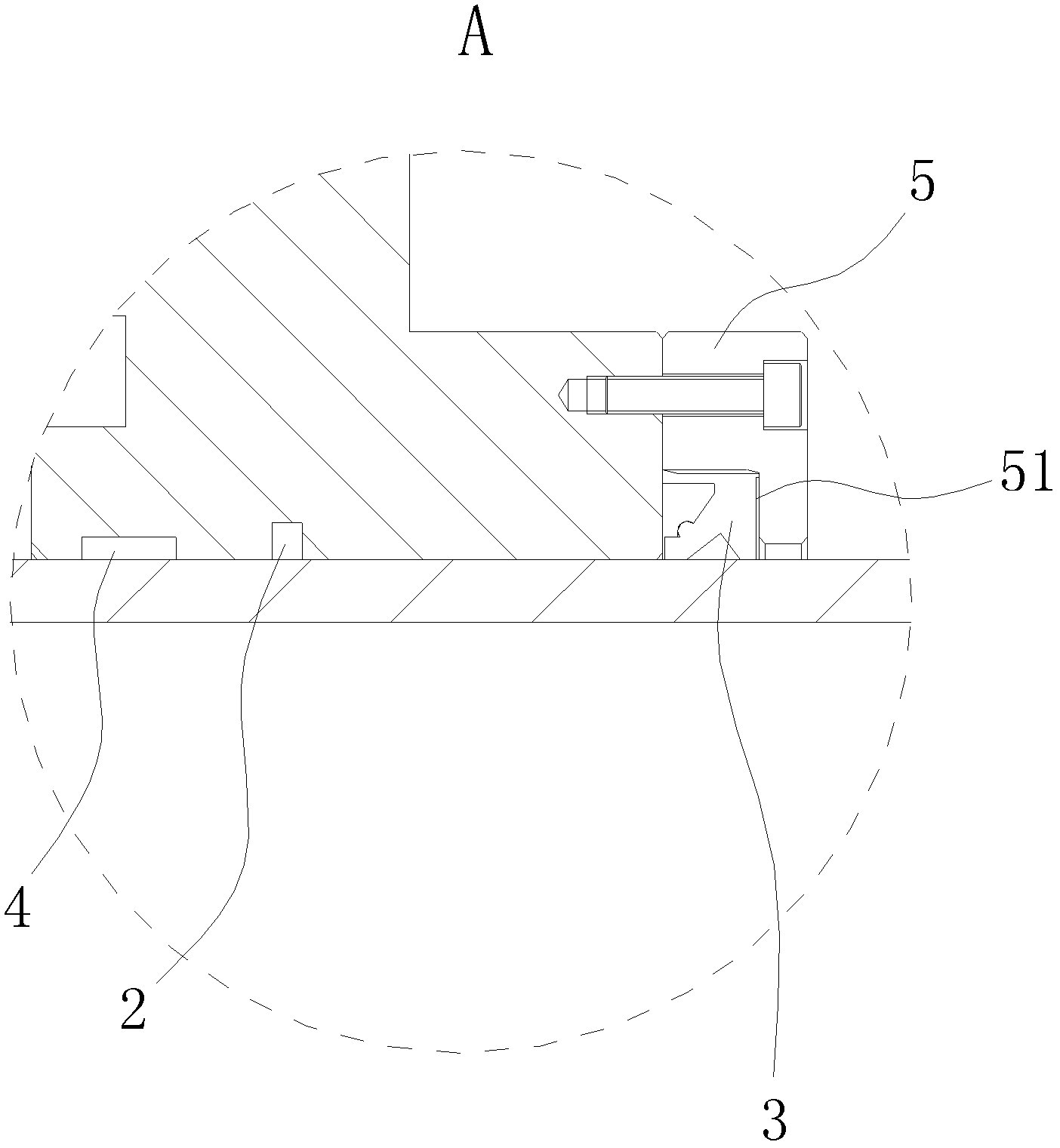

[0048] Please refer to figure 2 and image 3 ,in figure 2 It is a structural schematic diagram of the screw sealing mechanism of the boring bar of the scraping roller of the present invention, image 3 for figure 2 In the enlarged schematic diagram of part A, as shown in the figure, the screw sealing mechanism of the boring bar of the scraping machine of the present invention mainly includes: a flange 1, which is arranged on the opening 201 on the side of the oil receiver 20 close to the boring bar box 30; The outer edge of the flange 1 is fixedly connected to the wall plate of the opening 201 of the oil receiver, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com