Gapless gear transmission device and method for removing gear transmission gap

A technology of gear transmission and no backlash, which is applied in hoisting devices, components with teeth, portable lifting devices, etc., can solve the problems of increasing the axial size, the backlash of the teeth cannot be automatically compensated, and the structure is complex, etc., to achieve increased Axial size, wide range of application, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

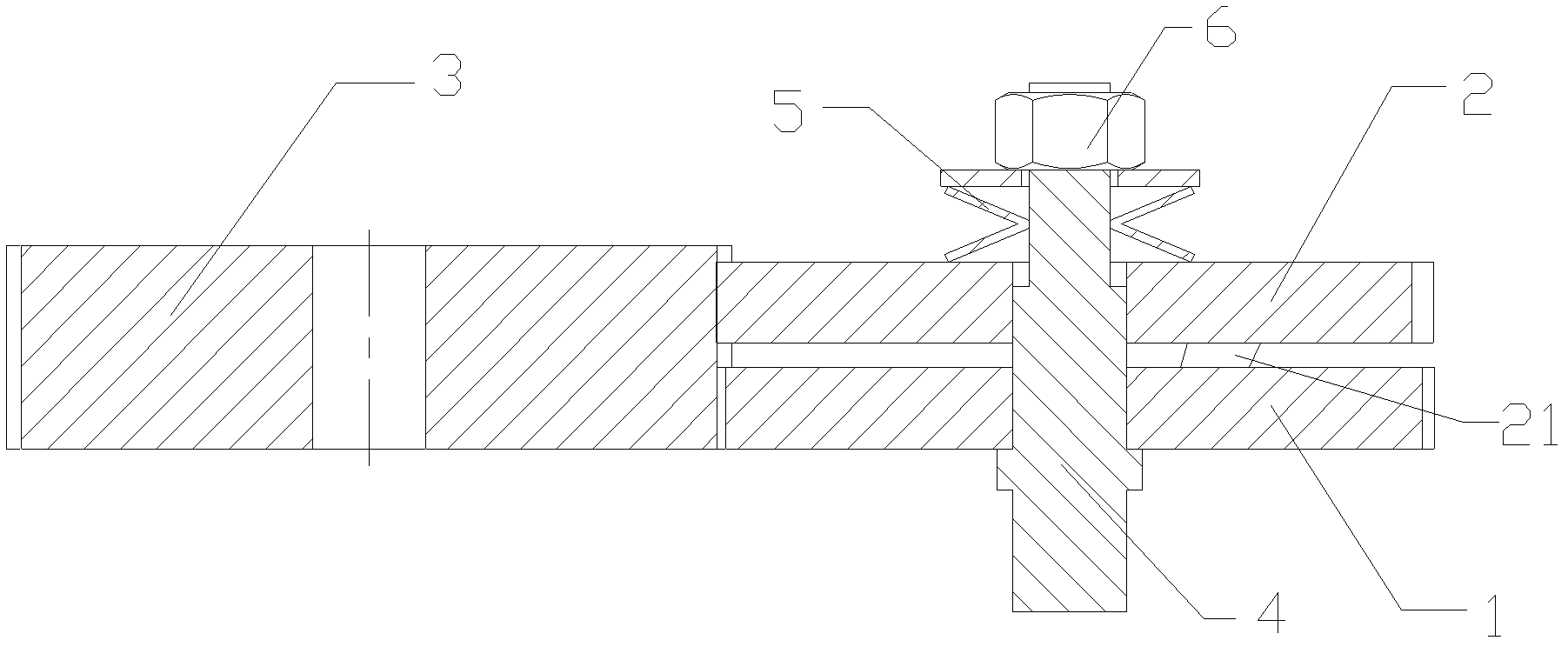

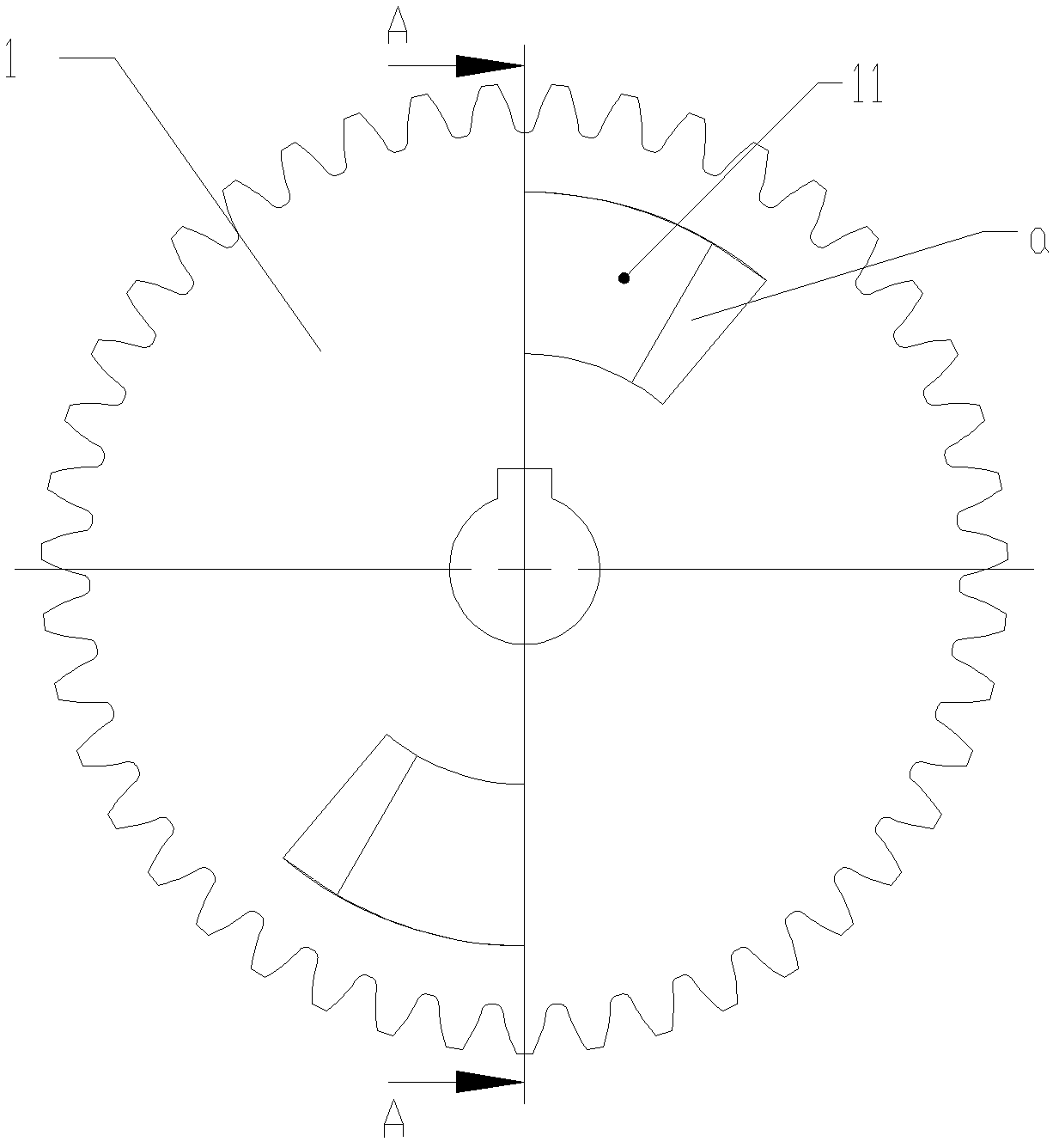

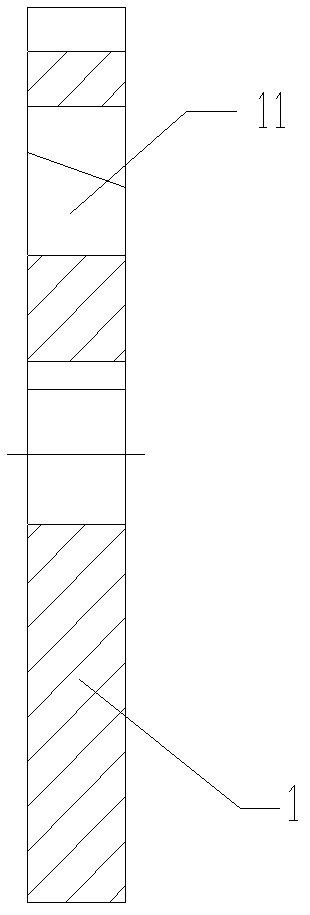

[0039] see Figure 1-5As shown, a backlash-free gear transmission includes a third gear 3 connected to a driving device such as an output shaft of a motor, and a first gear 1 and a first gear 1 that are simultaneously engaged with the third gear 3 and mounted on the gear shaft 4 in parallel. Second gear 2. The first gear 1 and the second gear 2 have the same gear modulus, the first gear 1 is fixed on the gear shaft 4 through a keyway, and a wedge-like hole 11 is provided on the gear surface; the second gear 2 is sleeved on the gear shaft 4, a spring 5 and an adjusting nut 6 are installed on the gear shaft 4 at the top of the second gear 2. The second gear 2 can rotate around the gear shaft 4, and can move axially through the spring 5 and the adjustment nut 6. A wedge-like hole 11 corresponding to the first gear 1 is provided on the second gear 2. The hole 11 matches the wedge-like protrusion 21 .

[0040] The wedge-like hole 11 of the first gear 1 and the wedge-like protrus...

Embodiment 2

[0045] A method for eliminating transmission gaps between gears, including a third gear 3 connected to the motor output shaft 4, and a first gear 1 and a second gear 2 that are simultaneously engaged with the third gear 3 and installed side by side on the gear shaft 4, The first gear 1 and the second gear 2 have the same gear modulus, and the first gear 1 and the second gear 2 are respectively provided with matching wedge-like holes 11 and wedge-like protrusions 21 . The side a of the wedge-like hole 11 arranged on the radial surface of the gear and the side b of the wedge-like protrusion 21 matching it are both spiral curved surfaces, and the other sides of the wedge-like hole 11 and the wedge-like protrusion 21 are all consistent with the first The surfaces of the gear 1 and the second gear 2 are perpendicular to each other; the stagger angle between the first gear 1 and the second gear 2 is adjusted by the mutual rotation between the sides a / B, and the transmission gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com