Flexible flywheel assembly

A flexible flywheel and assembly technology, applied in the field of flywheels, can solve the problems of complex flywheel structure, low material utilization rate, and difficult manufacturing, and achieve the effects of saving labor and energy, high material utilization rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

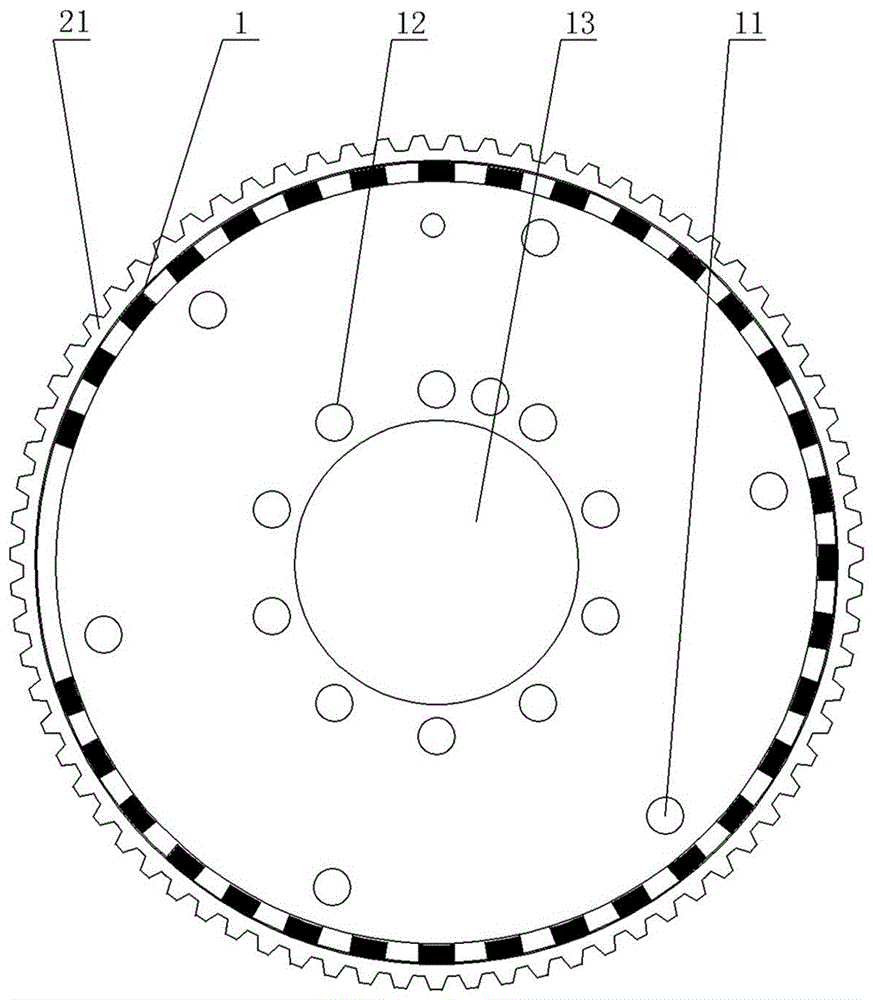

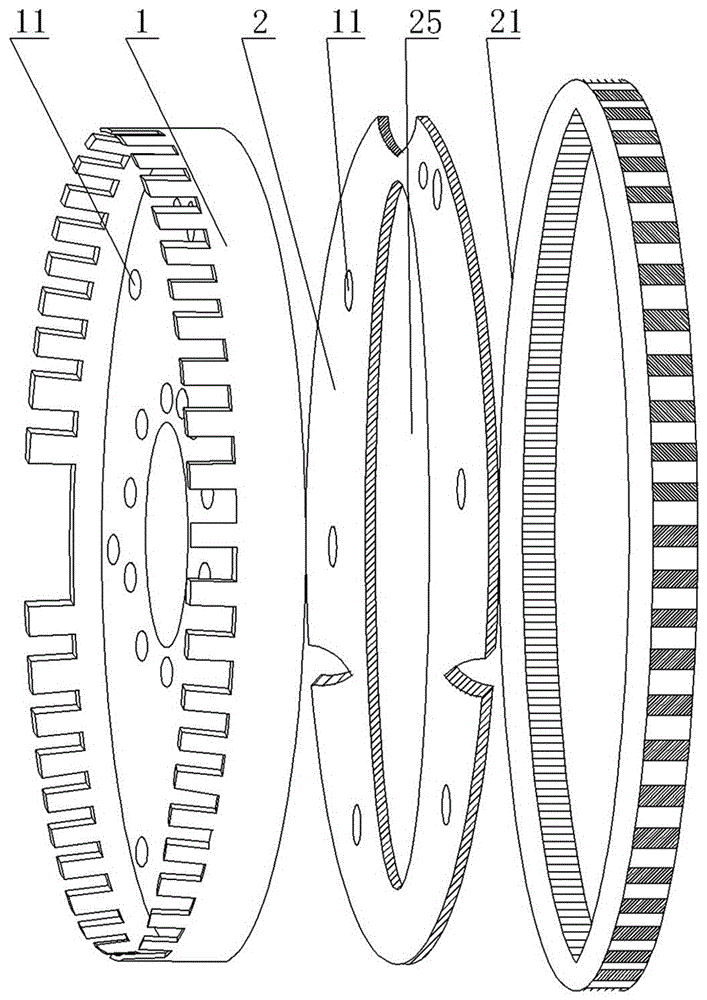

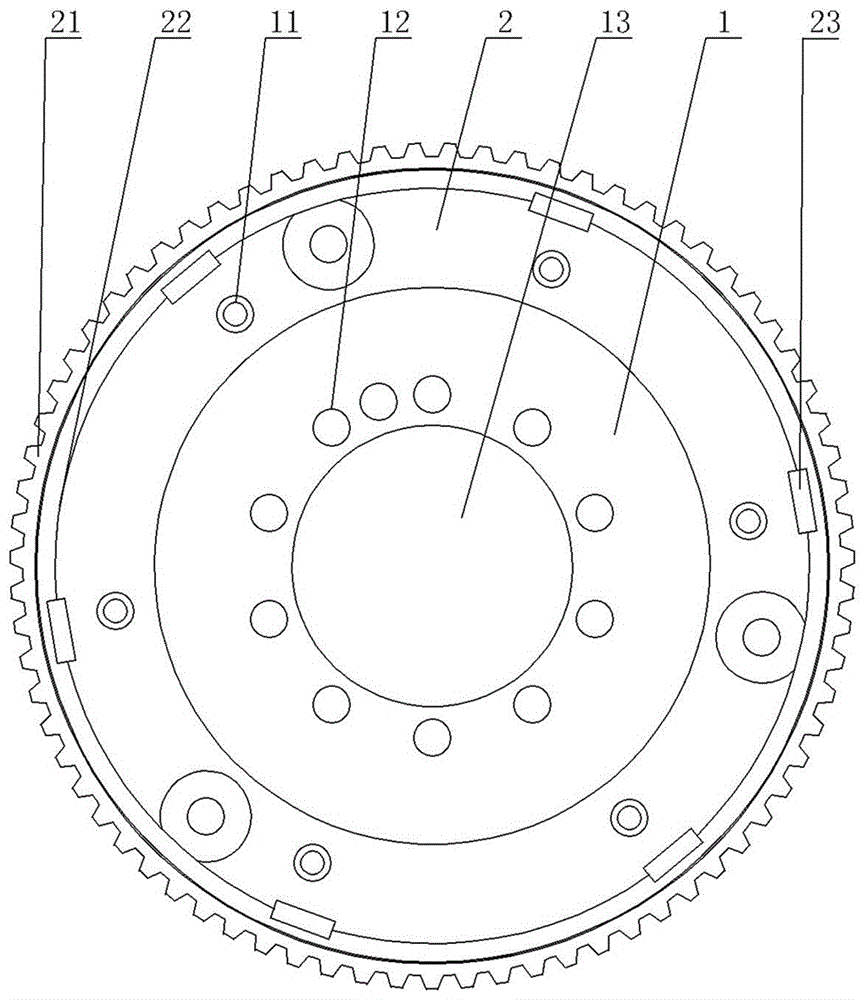

[0020] figure 1 It is a structural representation of the present invention. Depend on figure 1 combine figure 2 , 3 It can be seen that the flexible flywheel disc assembly is mainly composed of the signal disc 1 , the connection disc 2 , the flywheel ring gear 21 and the like. The thickness of the signal plate 1 is 2.5mm, and the thickness of the connection plate 2 is 3mm. The connection plate 2 and the signal plate 1 are respectively provided with 6 corresponding riveting holes 11 . The signal plate 1 and the connecting plate 2 are riveted together, and the bottom side wall of the connecting plate 2 is welded together with the ring gear 21 .

[0021] In order to reduce the stress after the connecting pad 2 and the signal pad 1 are recombined, the connecting pad is designed in a ring shape, and the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com