Low ebb electricity and waste heat recovering, storing and recycling system of internal combustion engine generator

A technology for internal combustion generators and waste heat recovery, which is applied in the field of peak-shaving systems, can solve problems such as unreasonable waste heat recovery schemes, low recovery rates, and increased fuel consumption per unit power, and achieve the effect of improving energy utilization efficiency and broadening utilization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

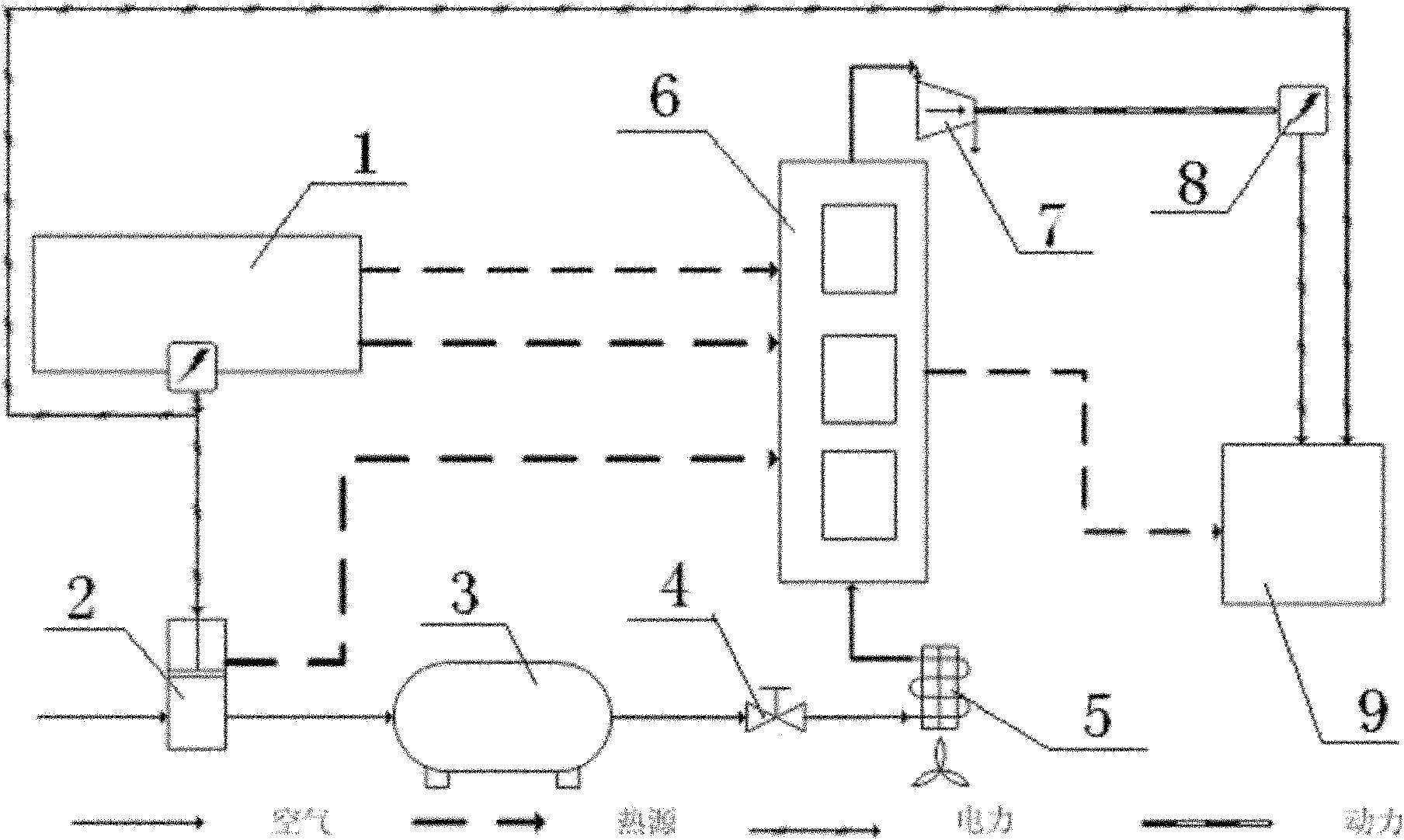

[0014] Such as figure 1 As mentioned above, the specific internal combustion generator low power and waste heat recovery, storage and reuse system includes: internal combustion generator 1; an air compression device composed of an air compressor 2 and a high-pressure air storage tank 3; a flow regulating valve 4; Compressed air preheating device 5 composed of annular fins and fans; heat storage / heat exchange device 6 composed of heat storage materials; expander 7; generator 8. Here, the internal combustion generator 1 is preferably a diesel generator, and the air compressor 2, the high-pressure gas storage cylinder 3, the compressed air preheating device 5, the heat storage / heat exchange device 6 and the expander 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com