Jet type sand dredger

A jet-type sand ship technology, applied to special-purpose ships, mechanically driven excavators/dredgers, ships, etc., can solve the problems of high cost, high energy consumption, and impact on quicksand production, so as to reduce operating costs and reduce The effect of large investment cost and large sand mining output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

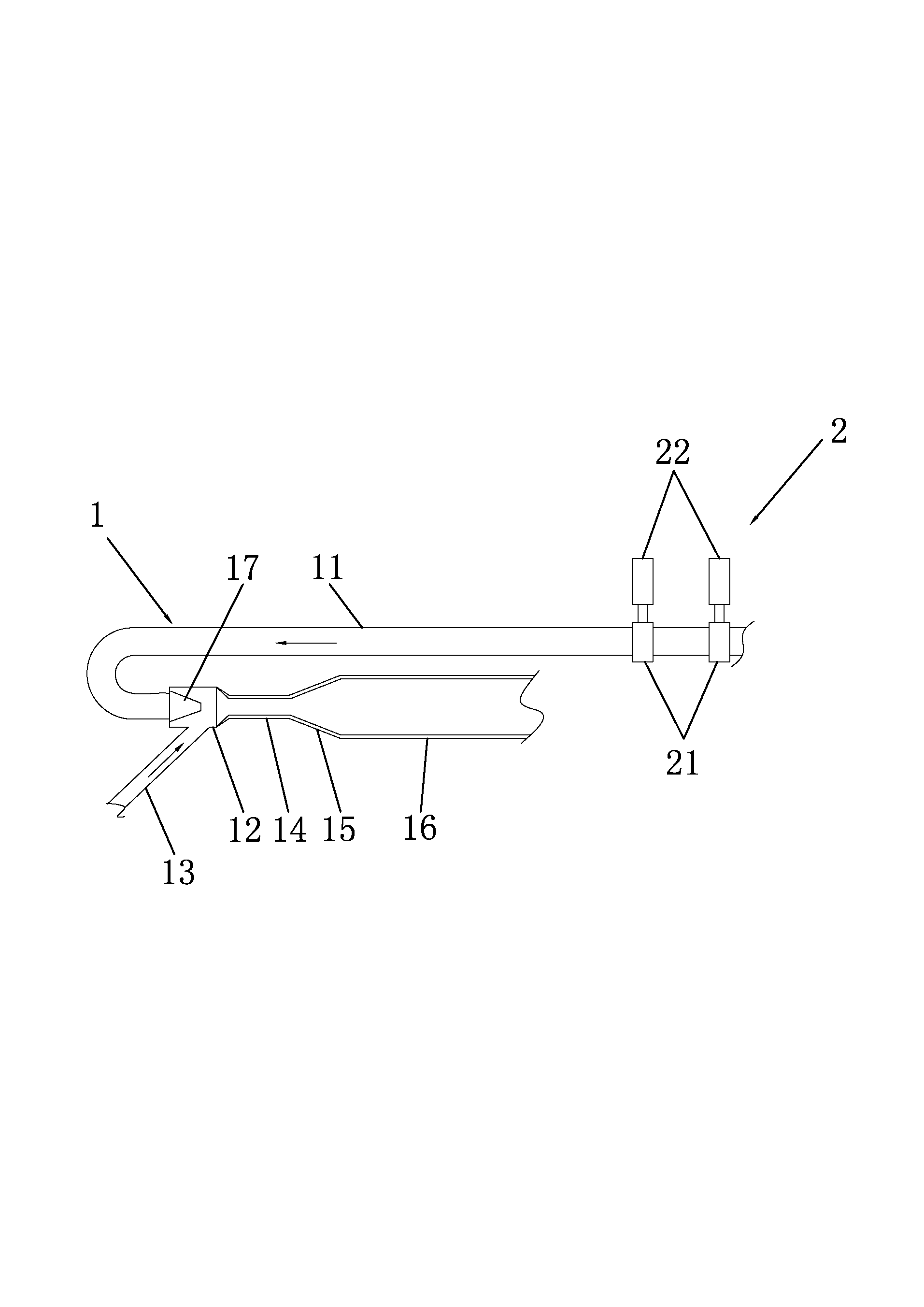

[0045] Such as figure 1 Shown, a kind of jet type dredging ship, it comprises sand pumping equipment, and dredging equipment comprises jet type dredging device 1 and water pump device 2, and jet type dredged device 1 comprises clean water pipe 11, vacuum chamber 12, upper sand nozzle 13 , mixing pipe 14, diffusion pipe 15 and upper sand pipe 16, vacuum chamber 12 is provided with nozzle 17, the water outlet port of clear water pipe 11 is connected with nozzle 17, and the outlet end of upper sand nozzle 13 is connected with vacuum chamber 12, and mixing pipe 14 is respectively Connect with vacuum chamber 12, diffuser pipe 15, diffuser pipe 15 is connected with the inlet end of upper sand pipe 16, water pump device 2 comprises water pump 21 and starting equipment 22, water pump 21 is provided with water inlet and water outlet, and the water outlet of water pump 21 and The water inlet port of the clean water pipe 11 is connected, and the water pump device 2 includes two water pum...

Embodiment 2

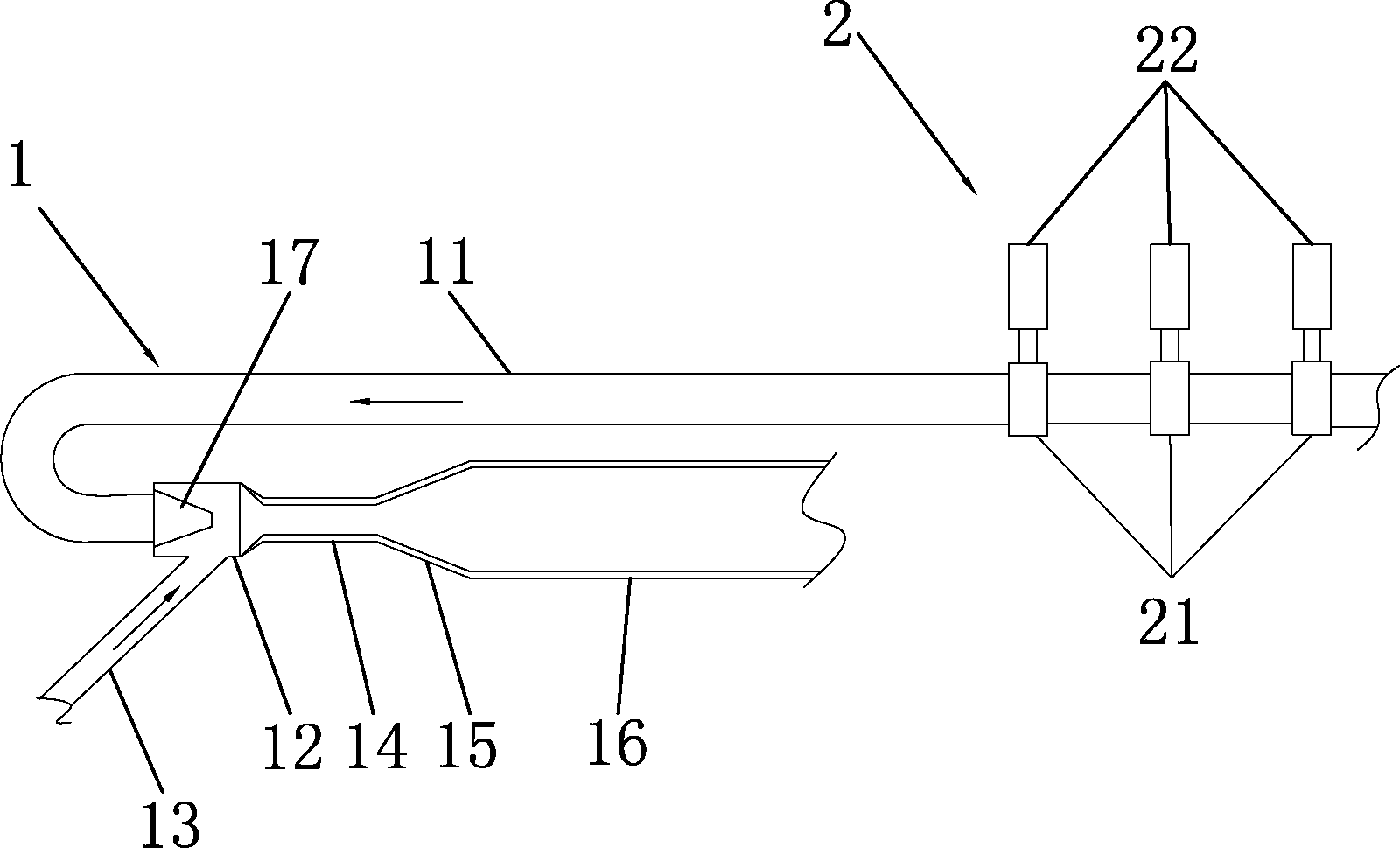

[0051] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the water pump device 2 of this embodiment includes three water pumps 21 and three starting equipment 22, each water pump 21 is connected to one starting equipment 22, and the water pump 21 and three starting equipment 22 are connected to each other. The water pumps 21 are connected in series. The starting device 22 is a diesel engine.

[0052] When the three water pumps 21 of the water pump device 2 are connected in series, Q 串 = Q 1 = Q 2 = Q 3 , H 串 =H 1 +H 2 +H 3 , and H=P / ρ (ρ is the density of water, 1000kg / m 3 ), it can be seen that P 串 =P 1 +P 2 +P 3 . When three water pumps 21 work in series, the total pressure produced is close to three times the pressure of one water pump 21, the pressure of the vacuum chamber 12 increases, the pressure generated inside and outside the upper sand nozzle 13 increases, and the suction force of the upper sand nozzle 13 incre...

Embodiment 3

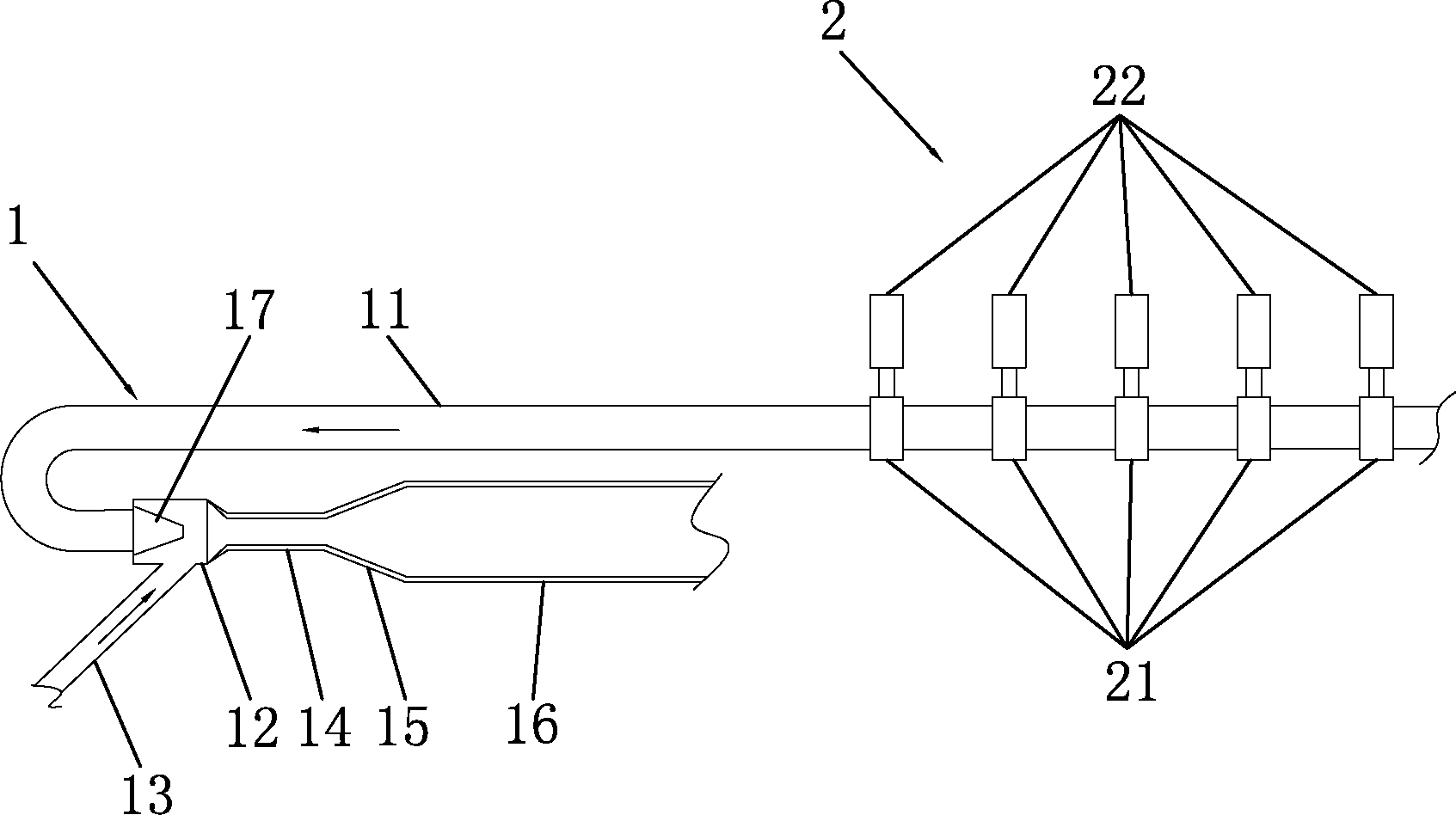

[0055] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the water pump device 2 of this embodiment includes five water pumps 21 and five starting equipment 22, each water pump 21 is connected to one starting equipment 22, and the water pump 21 and five starting equipment 22 are connected to each other. The water pumps 21 are connected in series. The starting device 22 is a diesel engine.

[0056] When the five water pumps 21 of the water pump device 2 are connected in series, Q 串 = Q 1 = Q 2 = Q 3 = Q 4 = Q 5 , H 串 =H 1 +H 2 +H 3 +H 4 +H 5 , and H=P / ρ (ρ is the density of water, 1000kg / m 3 ), it can be seen that P 串 =P 1 +P 2 +P 3 +P 4 +P 5 . When five water pumps 21 work in series, the total pressure produced is close to five times the pressure of one water pump 21, the pressure of the vacuum chamber 12 increases, the pressure generated inside and outside the upper sand nozzle 13 increases, and the suction of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com