Functional cigarette paper

A cigarette paper and functional technology, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of negative impact of cigarettes, affecting the smoking quality of Chinese cigarettes, toxic and harmful chemical components, etc., achieve moderate burning speed of cigarettes, and improve cigarette smoking. The effect of mouthfeel and safety of pyrolysis products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

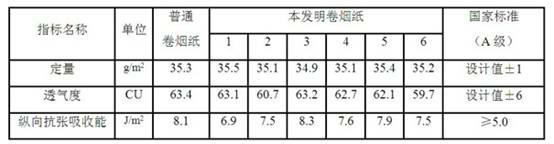

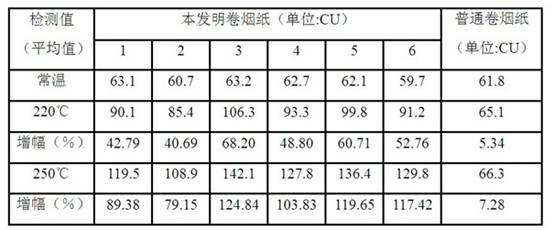

[0018] Example 1 : According to the description of the implementation process for the production of 1 ton of cigarette paper: 76 kg (7.6% by weight) of polylactic acid fibers (Jiaxing Pulilai New Material Co., Ltd.) with an average fiber length of 1.4mm are added to the pulping section, and needle leaves 224 kg of pulp (22.4% by weight), 400 kg of broadleaf pulp (40% by weight), 300 kg of calcium carbonate (30% by weight), and mix them evenly in the pulp mixing tank, press cigarettes The conventional paper production process is used for copying. After the cigarette paper is first dried and formed, 20 kg of citrate (potassium citrate and sodium citrate in a weight ratio of 1:1) is added in the sizing section. The basis weight, air permeability and air permeability increase of the cigarette paper are shown in Table 1 and Table 2.

Embodiment 2

[0019] Example 2 : According to the description of the implementation process of producing 1 ton of cigarette paper: 10 kg (1% by weight) of polyglycolic acid fiber (Changchun Shengboma Biomaterials Co., Ltd.) with an average fiber length of 0.8mm is added to the pulping section, 300 kg of coniferous pulp (30% by weight), 390 kg of broadleaf pulp (39% by weight), 300 kg of calcium carbonate (30% by weight), and mix them evenly in the slurry mixing tank, press The conventional production process of cigarette paper is copied. After the cigarette paper is first dried and formed, 20 kg of citrate (potassium citrate and sodium citrate in a weight ratio of 1:1) is added in the sizing section. The basis weight, air permeability and air permeability increase of the cigarette paper are shown in Table 1 and Table 2.

Embodiment 3

[0020] Example 3 : Description of the implementation process based on the production of 1 ton of cigarette paper: Add 150 kg (15% by weight) of polylactic acid powder (Shenzhen Yisheng New Material Co., Ltd.) 284 kg of pulp (28.4% by weight), 390 kg of hardwood pulp (39% by weight), 176 kg of calcium carbonate (17.6% by weight), and mix them evenly in the pulp mixing tank, press the cigarette paper Conventional production process for copying. After the cigarette paper is first dried and formed, 20 kg of citrate (potassium citrate and sodium citrate in a weight ratio of 1:1) is added in the sizing section. The basis weight, air permeability and air permeability increase of the cigarette paper are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com